Novel multifunctional vegetable strapping machine

A multi-functional, strapping machine technology, applied to the parts of strapping machinery, strapping materials, etc., can solve the problems of unreasonable structural design, inconvenient operation, and unstable operation of the vegetable strapping machine, and achieve easy movement, portability, The effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

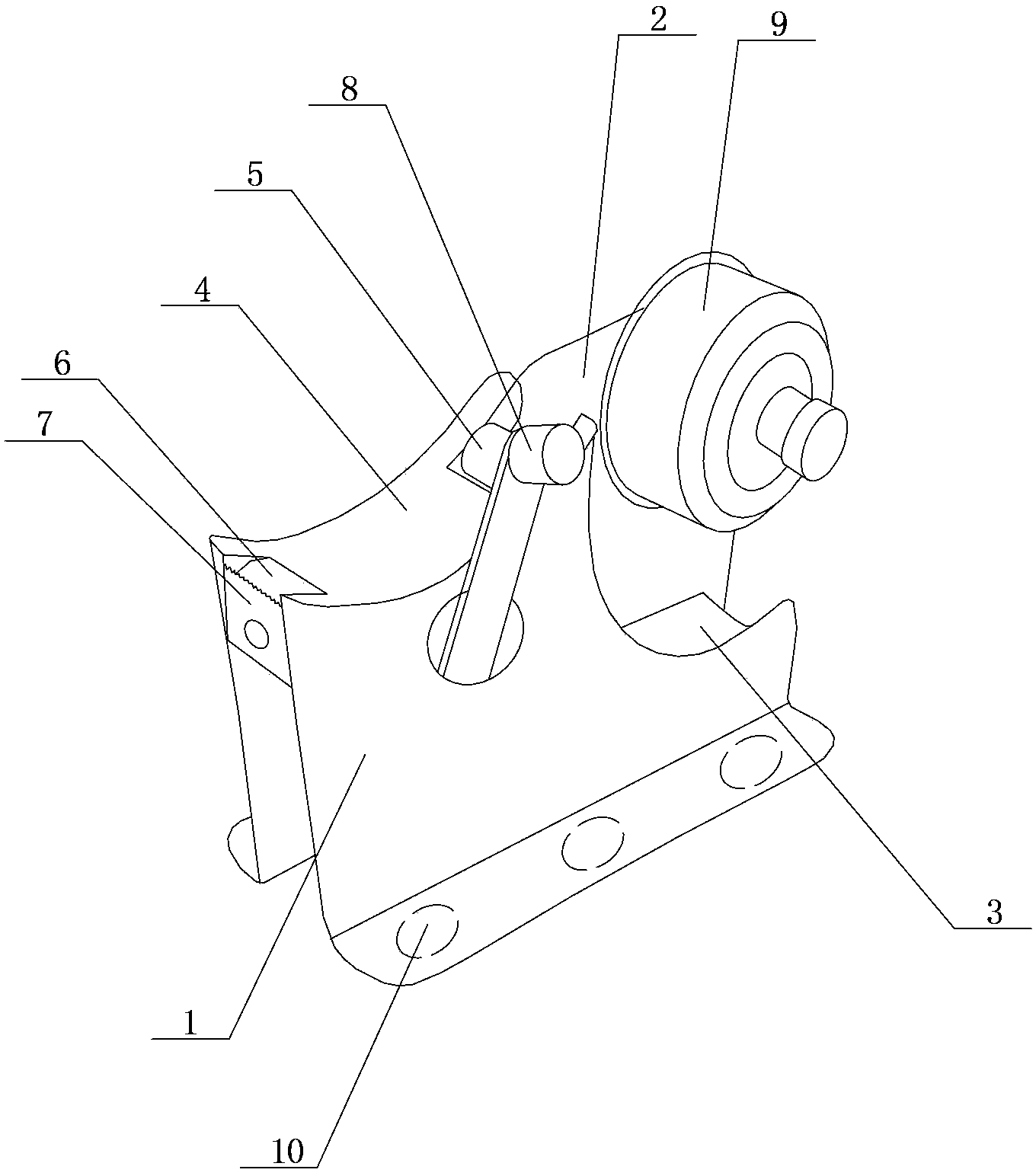

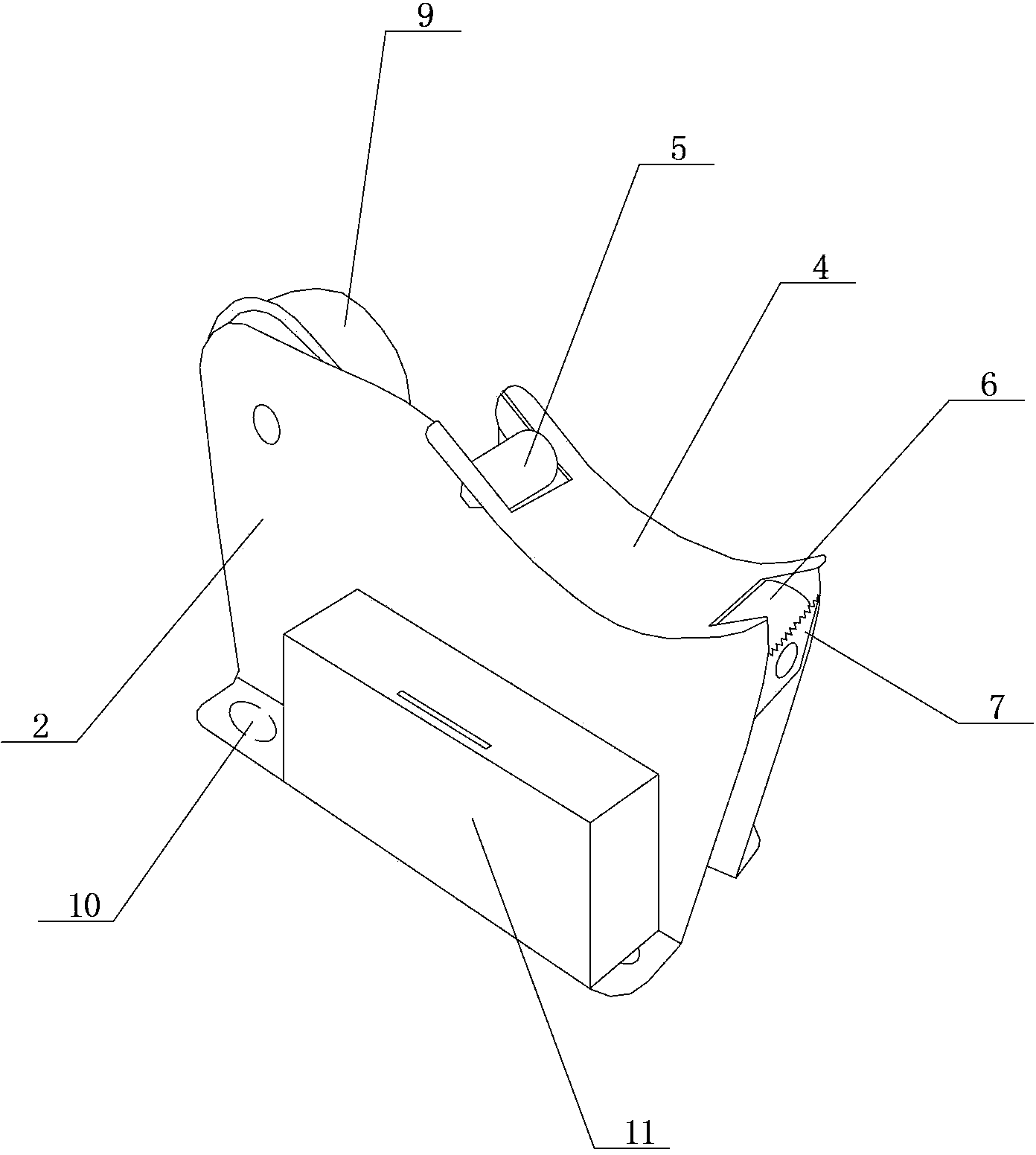

[0011] refer to figure 1 , figure 2 , the specific embodiment adopts the following technical scheme: it is composed of the first side plate 1, the second side plate 2, the bottom plate 3, the arc-shaped stainless steel blade 4, the first roller 5, the second roller 6, the sawtooth cutting plate 7 , manual handle 8, tape roller 9, suction cup 10, and tape placement box 11; Arc-shaped stainless steel blades 4 are arranged between them, and the two ends of the arc-shaped stainless steel blades 4 are respectively provided with a first roller 5 and a second roller 6, and the sawtooth cutting edge 7 is fixed on the outside of the second roller 6 by screws. The shaking handle 8 is arranged on the first side plate 1, and the tape roller 9 is fixed on the upper end of one side of the second side plate 2 by screws. The bottoms of the first side plate 1 and the second side plate 2 are all provided with several suction cups 10. Adhesive tape placement boxes 11 are arranged on the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com