Turbomachine stator internal shell with abradable material

一种涡轮机、内壳体的技术,应用在轴向涡轮机压缩机的压缩级,压缩级的密封领域,能够解决不可能明显改善密封等问题,达到制造成本降低、减小泄漏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the following description, the terms inner and outer refer to a position relative to the axis of rotation of the axial turbine.

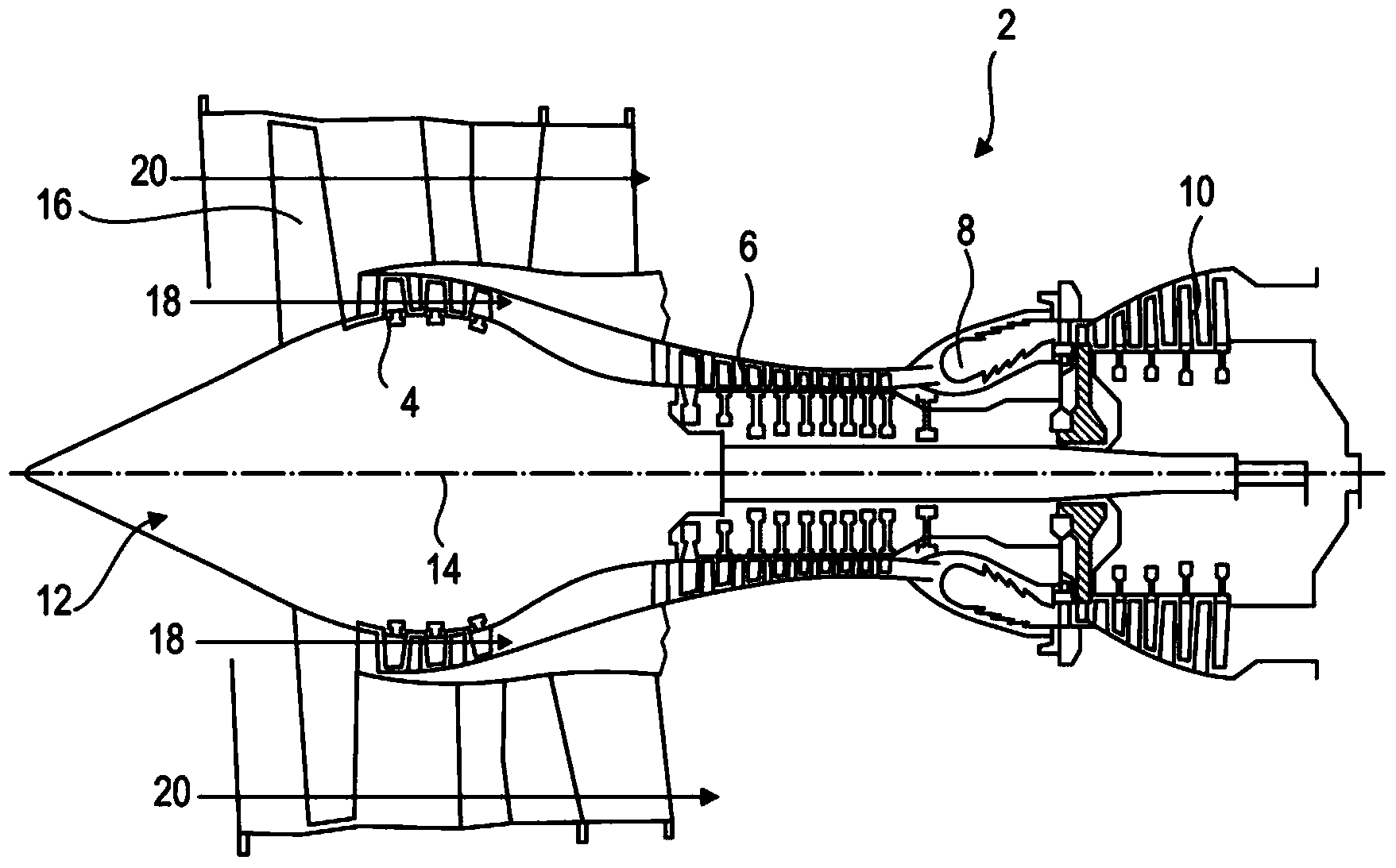

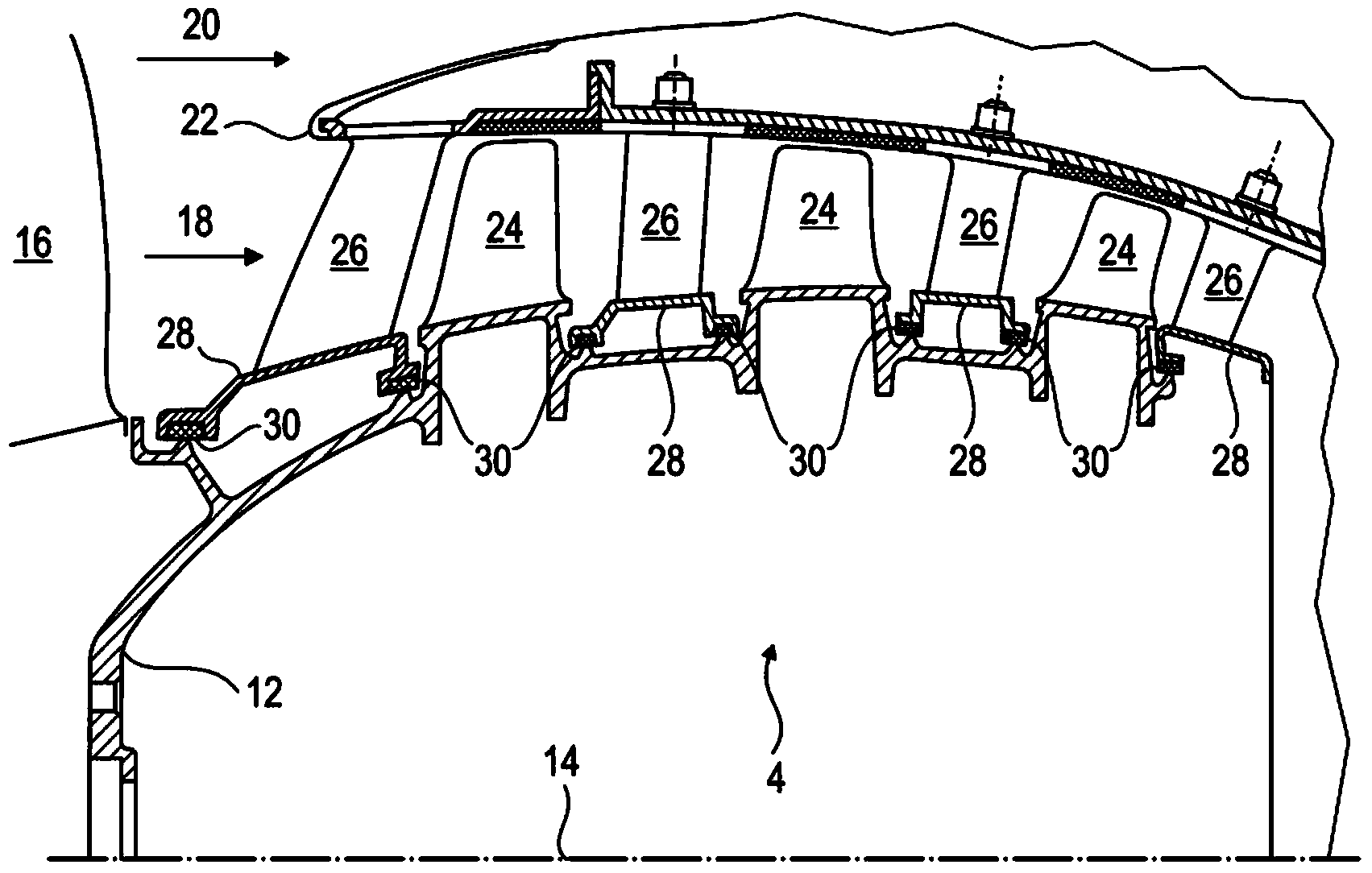

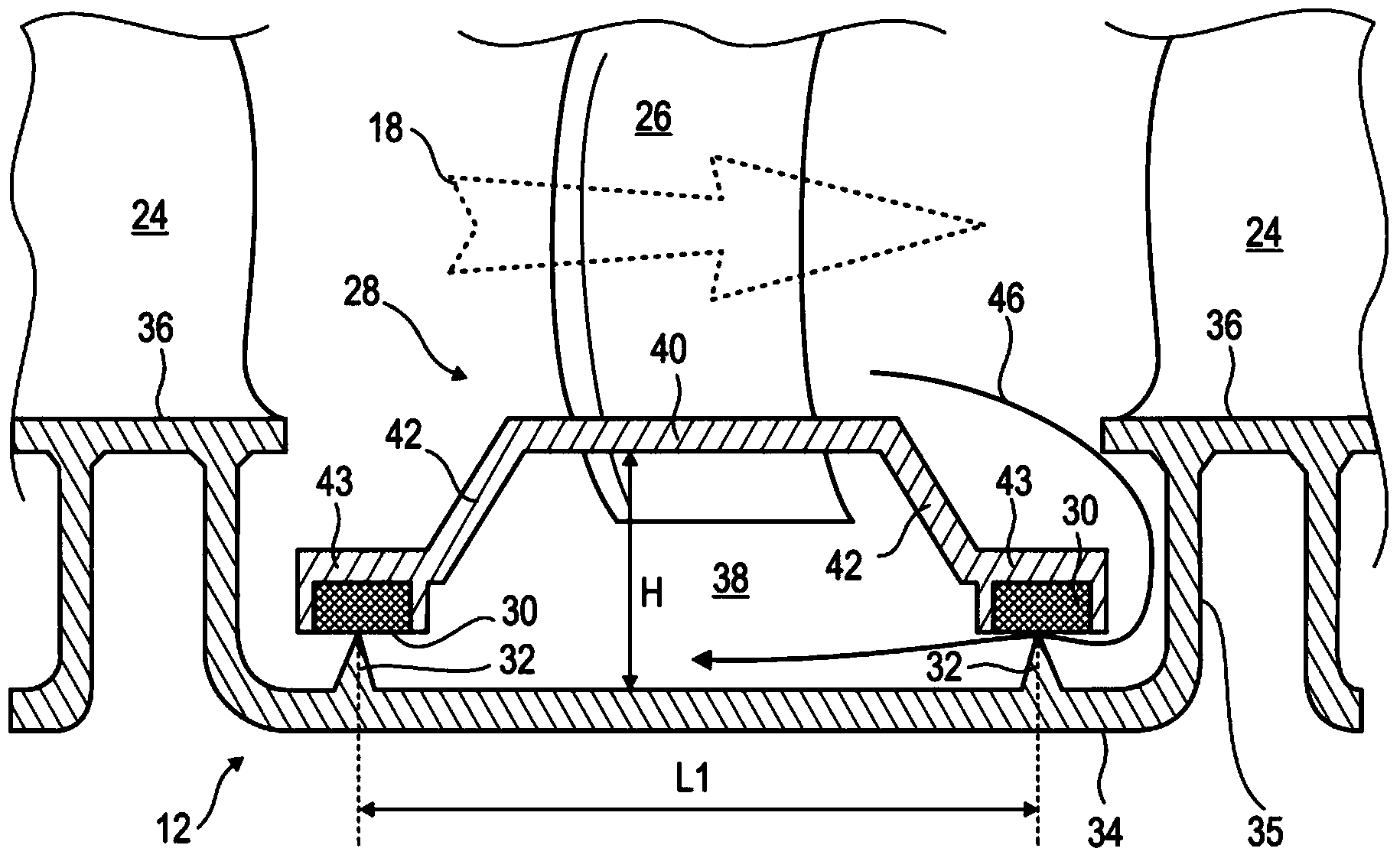

[0054] figure 1 An axial turbine is shown. In this example, it is a twin-flow turboprop 2 ; it could also be a turbojet 2 . The turboprop 2 comprises a first compression stage, a so-called low-pressure compressor 4 , a second compression stage, a so-called high-pressure compressor 6 , a combustion chamber 8 and one or more turbine stages 10 . In operation, the mechanical power of the turbine 10 is transmitted through the central shaft to the rotor 12 and drives the two compressors 4 and 6 . The reduction mechanism increases the rotational speed transmitted to the compressor. Alternatively, the different turbine stages may each be connected to the compressor stage by a concentric shaft. These concentric shafts include several rows of rotor blades associated with rows of stator blades. The rotation of the rotor about its axis of rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com