Band gap adjustable type phononic crystal vibration isolator based on shape memory alloy

A phononic crystal and memory alloy technology, which is applied in the field of vibration isolators, can solve the problems of non-adjustable band gap, narrow vibration isolation frequency range and working space limitation of one-dimensional phononic crystal vibration isolators, so as to expand the vibration isolation frequency. or frequency range, outstanding vibration isolation effect, and low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

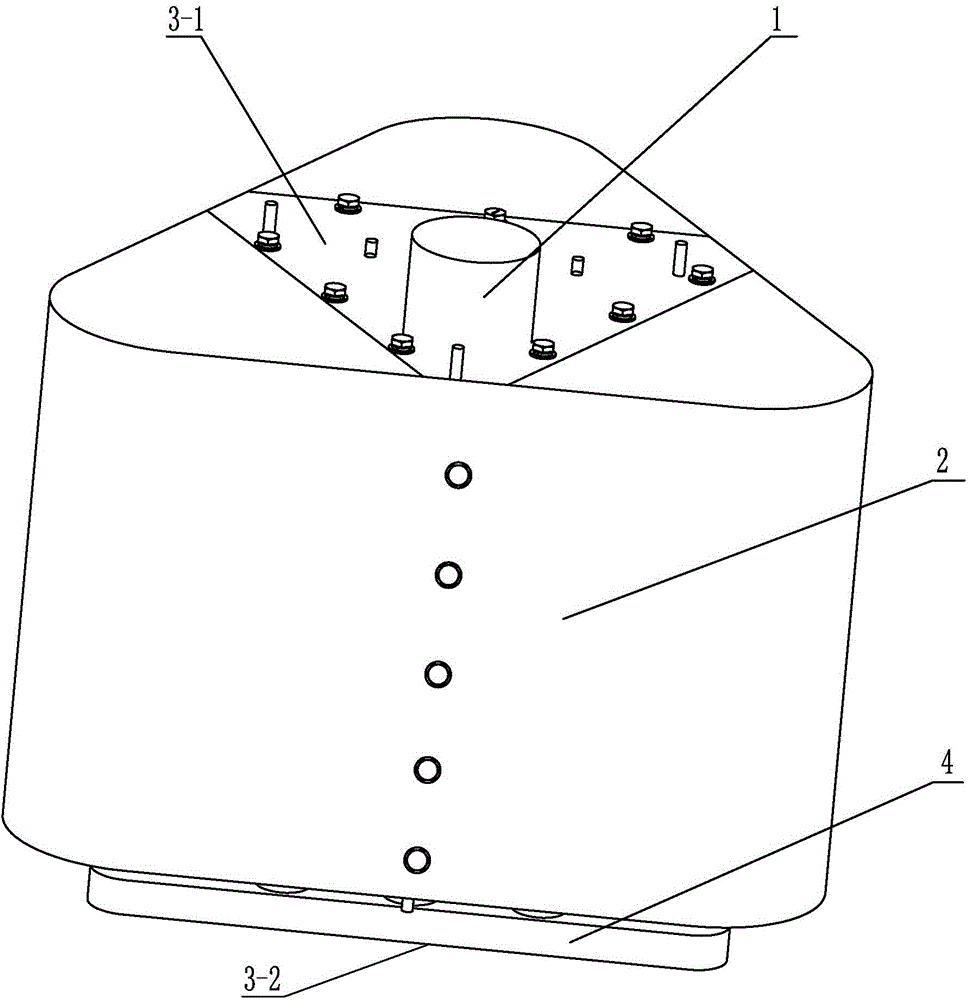

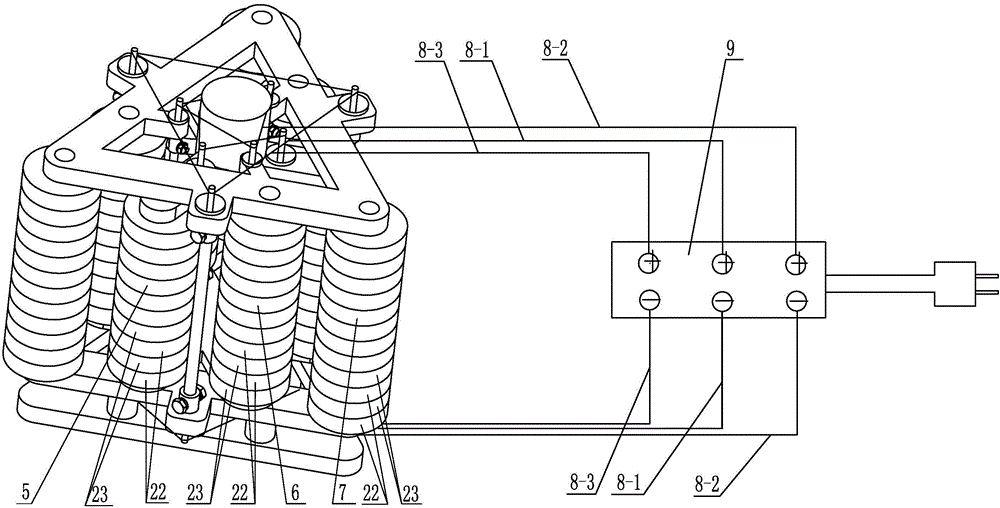

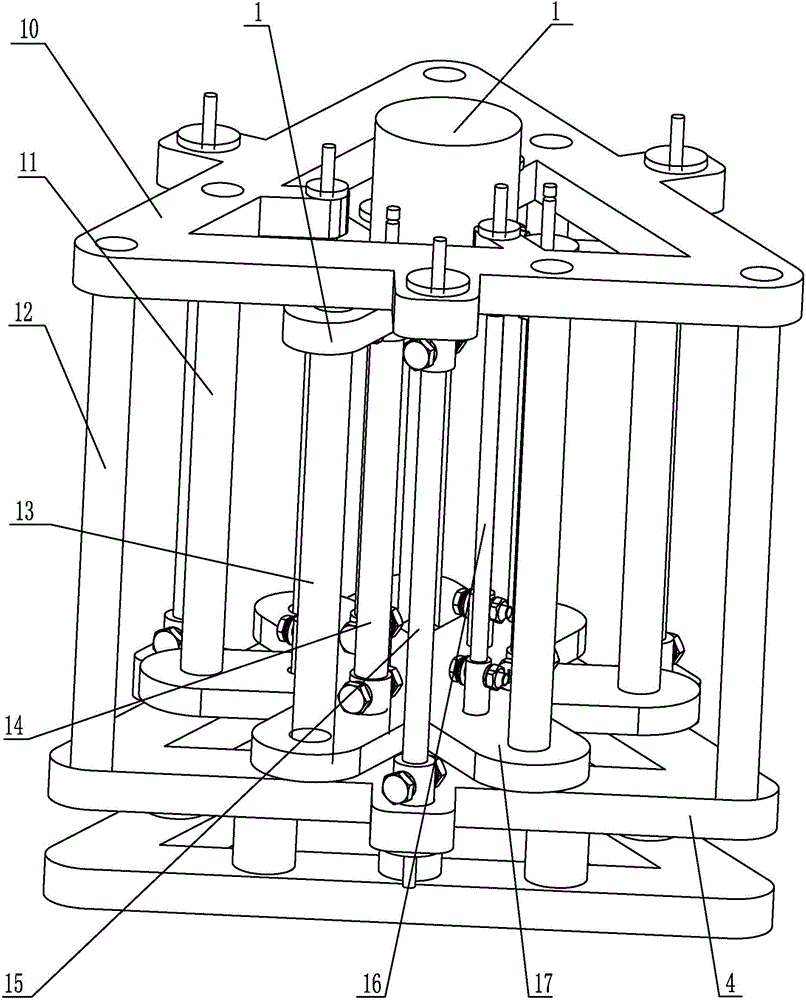

[0017] Specific implementation mode one: combine Figure 1-Figure 3 as well as Figure 4 Explain that a phononic crystal vibration isolator based on a shape memory alloy with adjustable bandgap in this embodiment includes a vibration input support 1, a side skin 2, an upper skin 3-1, a lower skin 3-2, two Level 1 vibration isolation upper support 10, vibration output support 4, level 1 vibration isolation lower support 17, three level 1 vibration isolation phononic crystal support columns 13, three level 2 vibration isolation phononic crystal support columns 11, three level 3 phonon crystal support columns Vibration isolation phononic crystal support column 12, three sets of first-level vibration isolation shape memory alloy compression drive components 14, three sets of second level vibration isolation shape memory alloy compression drive components 16, three sets of third level vibration isolation shape memory alloy compression drive components Drive assembly 15, three sets...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 2 with image 3 Note that each set of first-level vibration-isolated phononic crystal oscillator components 5, each set of second-level vibration-isolated phononic crystal oscillator components 6, and each set of three-level vibration-isolated phononic crystal oscillator components 7 in this embodiment are composed of a plurality of circular rings The first vibration-isolated phononic crystal oscillator 22 is composed of a plurality of circular-shaped second vibration-isolated phononic crystal oscillators 23 that are consistent with the number of circular-shaped first vibration-isolated phononic crystal oscillators 22, and each circular-shaped first vibration-isolated phononic crystal oscillator 23 A vibration-isolated phononic crystal oscillator 22 is made of aluminum, lead or copper, and each ring-shaped second vibration-isolated phononic crystal oscillator 23 is made of epoxy resin or nitrile rubber; the primary v...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 5 with Image 6 Note that each set of first-level vibration-isolated phononic crystal oscillator components 5, each set of second-level vibration-isolated phononic crystal oscillator components 6, and each set of three-level vibration-isolated phononic crystal oscillator components 7 in this embodiment include a plurality of local Resonance type phononic crystal local oscillator 21, each local resonance type phononic crystal local oscillator 21 is a cylindrical structure with inner and outer double layers glued together; the first-level vibration isolation phononic crystal support column 13, the second-level isolation Both the vibrating phononic crystal support column 11 and the three-stage vibration-isolation phononic crystal support column 12 are bonded with a plurality of local resonant phononic crystal local oscillators 21 arranged at regular intervals. In this way, the overall local resonance type phononic cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com