Method for shifting gears of transmission device gear-shifting transmission capable of being switched between at least two transmission levels

A transmission and transmission technology, applied in transmission control, elements with teeth, belts/chains/gears, etc., can solve problems such as increasing manufacturing costs, and achieve the effect of small manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

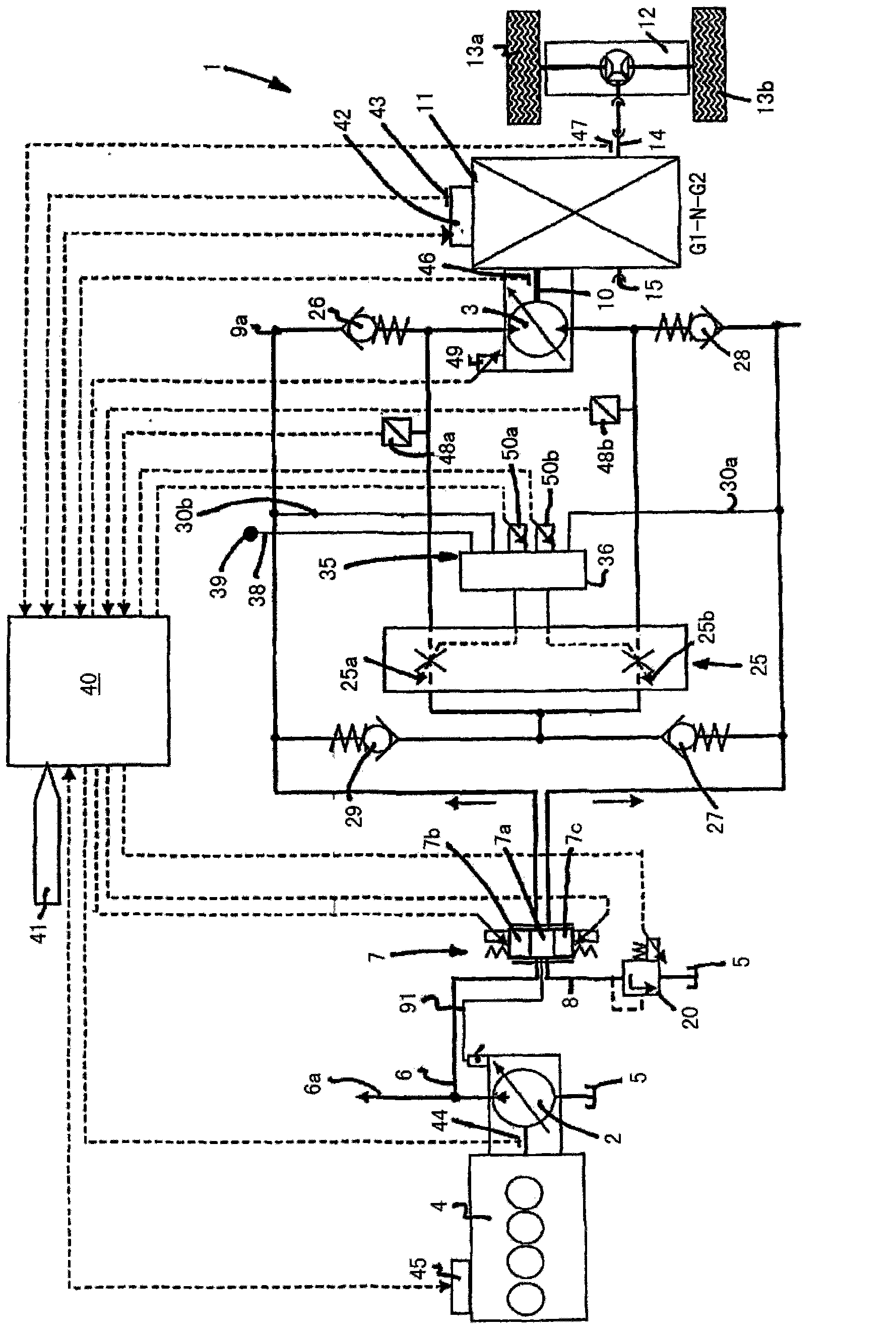

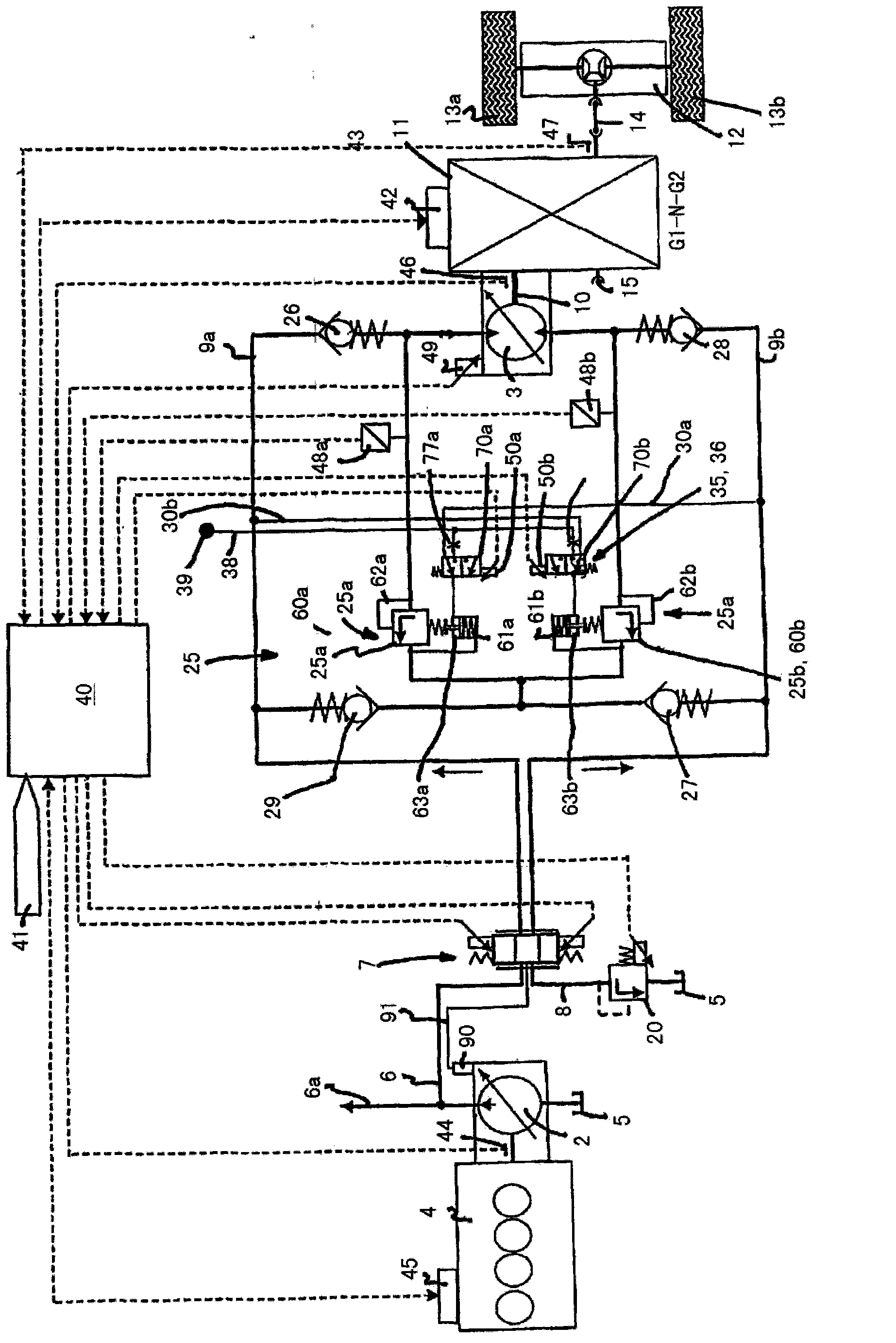

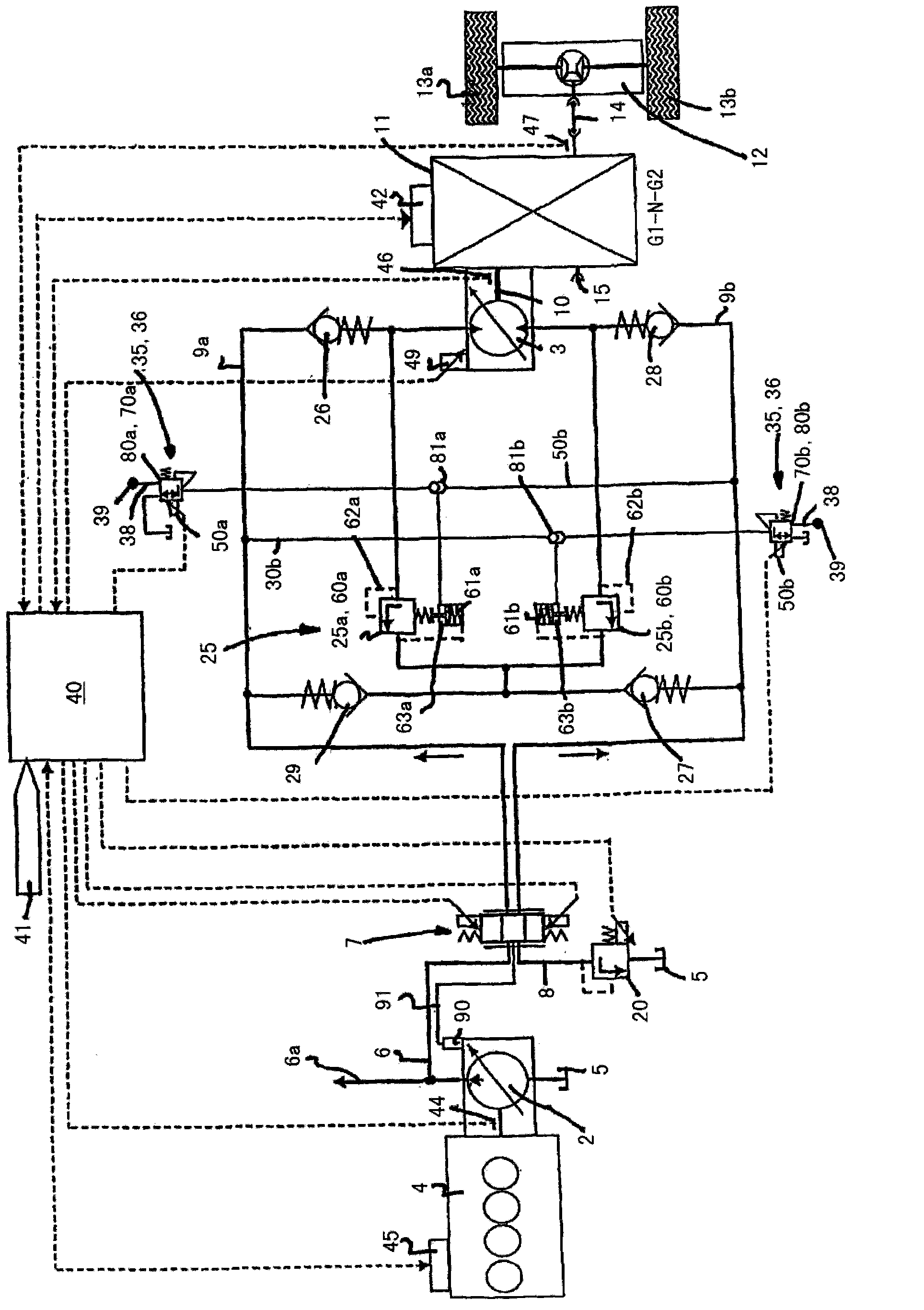

[0048] exist figure 1 A circuit diagram of an inventive transmission 1 of a working machine, for example an excavator, is shown in .

[0049] The chassis 1 comprises a hydrostatic transmission in an open circuit, which has a pump 2 with an adjustable fluid intake per revolution and a hydraulic motor 3 connected to the pump 2 in an open circuit. For driving, the pump 2 is connected to a drive motor 4 , for example an internal combustion engine. The pump 2 is connected at the input to a container 5 and delivers pressure medium into a delivery line 6 . In order to control the movement direction and movement speed of the hydraulic motor 3, a control reversing valve 7 limited in neutral is designed. The control directional control valve 7 is connected to the delivery line 6 , a container line 8 leading to the container 5 and a first pressure medium line 9 a leading to the hydraulic motor 3 and a second pressure medium line leading to the hydraulic motor 3 On line 9b. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com