Device for driving helicopter wheel to rotate

A belt-rotating and wheel-based technology, applied in the field of aircraft strength test devices, can solve problems such as difficult installation and debugging, cumbersome and complicated technology, and increased test costs, so as to improve authenticity and accuracy, improve test efficiency, and save test costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

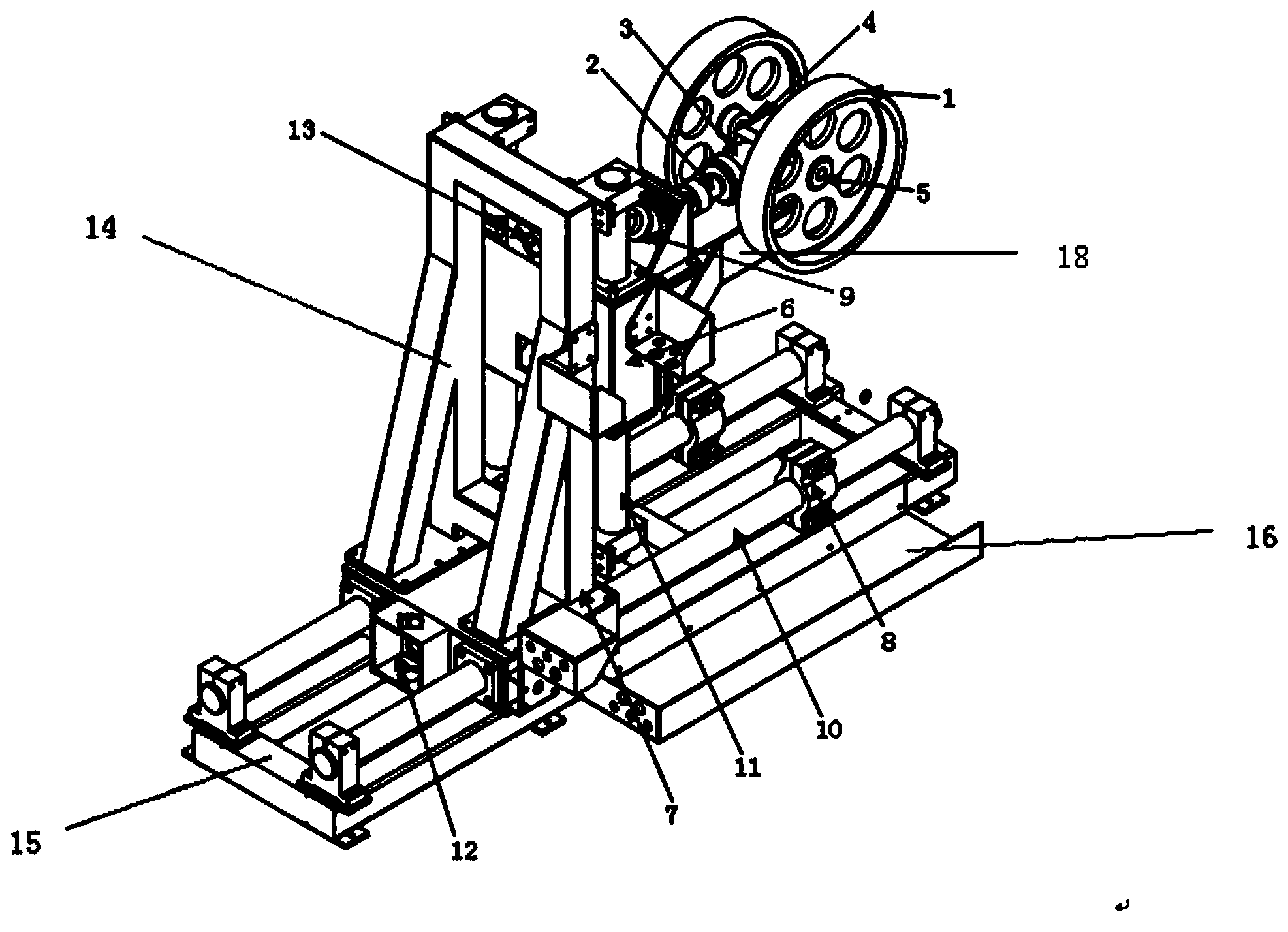

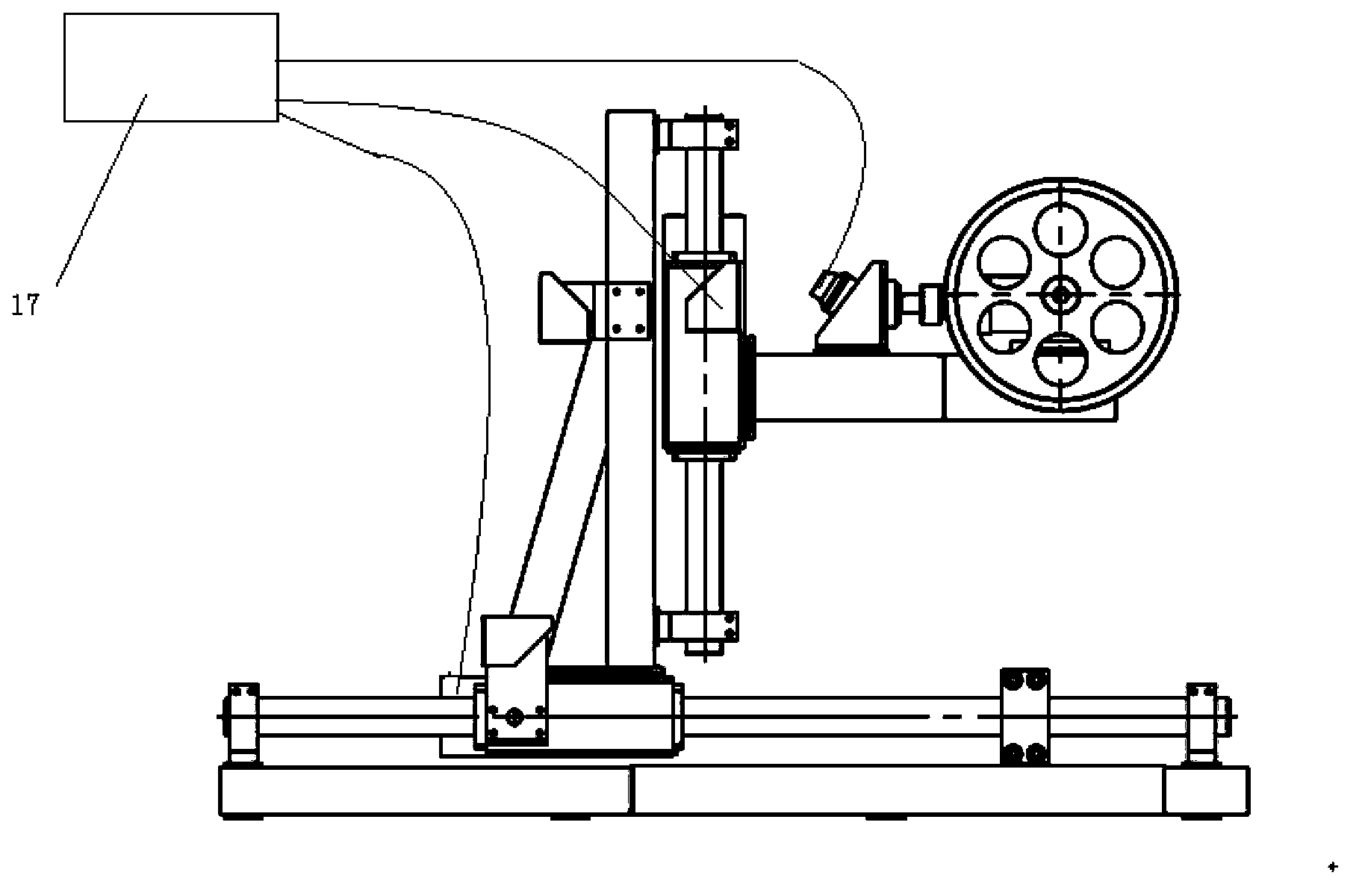

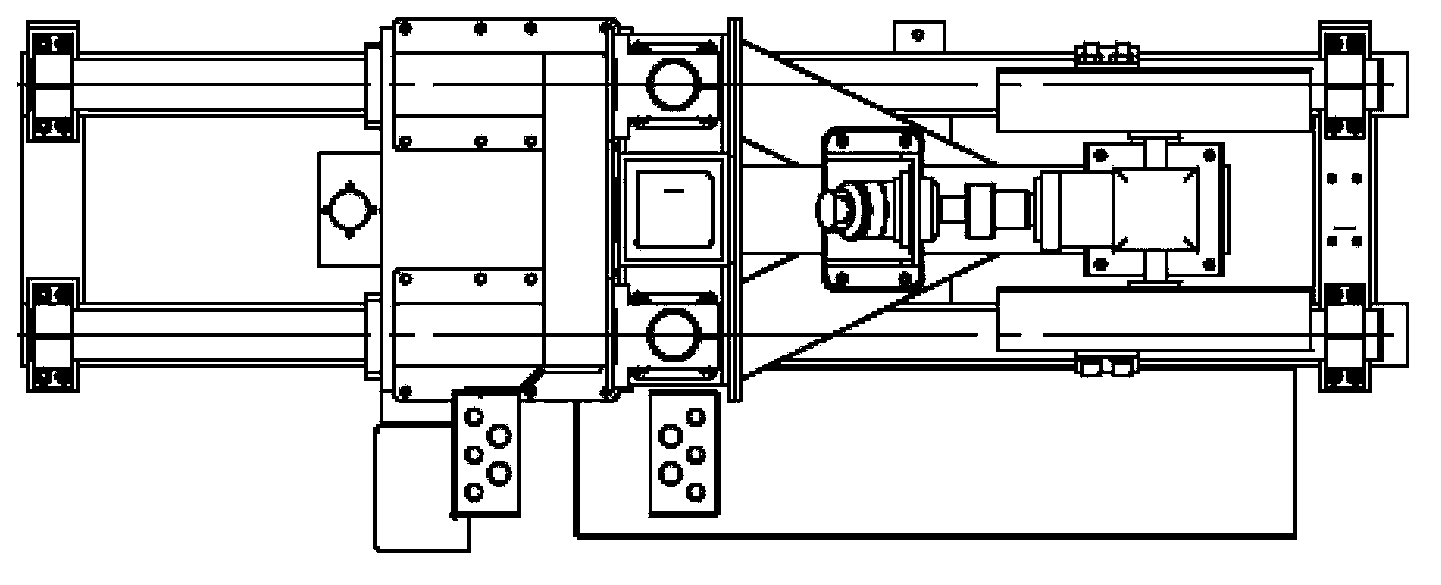

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings. Please refer to the attached figure 1 , 2 , 3, 4.

[0012] Wheel belt rotation device, including friction wheel 1, transmission shaft 2, hydraulic motor 3, gearbox 4, rotating shaft 5, lifting mechanism 6, retracting mechanism 7, limit hoop 8, servo valve 9, horizontal slide rail 10 , vertical slide rail 11, horizontal manipulation 12, up and down manipulation 13, vertical support 14, horizontal support 15, abutment 16, control system 17 and mounting bracket 18, wherein,

[0013] The upright support 14 and the horizontal support 15 are all rectangular frames, the horizontal support 15 is fixedly installed on the abutment 16, the horizontal slide rail 10 is fixedly installed on the horizontal support 15, and the retractable mechanism 7 is slidingly installed on the horizontal slide rail 10, and the vertical support 14 feet are fixedly installed on the retract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com