Method for detecting heat sealing defects of external packaging transparent film

A transparent film and detection method technology, which is applied in the direction of optical testing flaws/defects, etc., can solve problems such as defects, packaging bubbles, and slack, and achieve the effects of effect and objectivity, automation, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

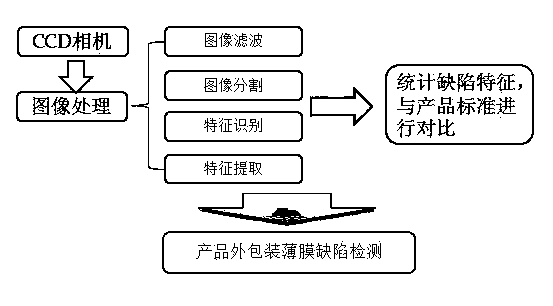

[0012] The present invention will be further described below in conjunction with the accompanying drawings. The specific implementation of the present invention is described by taking the detection of the side defects of the transparent film of a small box of a certain product as an example.

[0013] like figure 1 As shown, the present invention uses a CCD camera installed on the production line to collect information on the outer packaging film of the product, converts the collected information into digital image information and inputs it into a computer for image processing.

[0014] The image processing toolbox of MATLAB is used for image processing. Firstly, the collected digitized image is preprocessed, the image size is adjusted and the gray scale is processed, and the image noise is reduced by filtering technology.

[0015] The median filter is used for denoising, and the filtering window is a 3×3 square window.

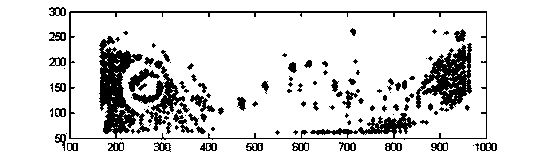

[0016] The preprocessed image is segmented to obtain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com