Pigment dispersion and yellow resist composition for color filter and ink composition containing the pigment dispersion

A technology of pigment dispersion and pigment yellow, applied in pigment slurry, chemical instruments and methods, instruments, etc., can solve problems such as weak light fastness, and achieve the effect of excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

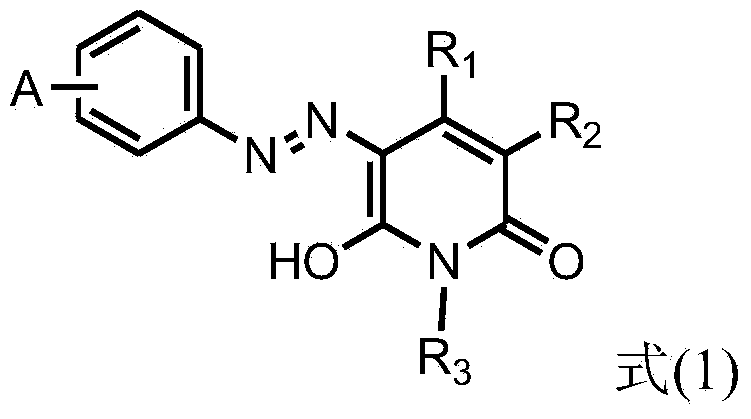

Method used

Image

Examples

Embodiment 1

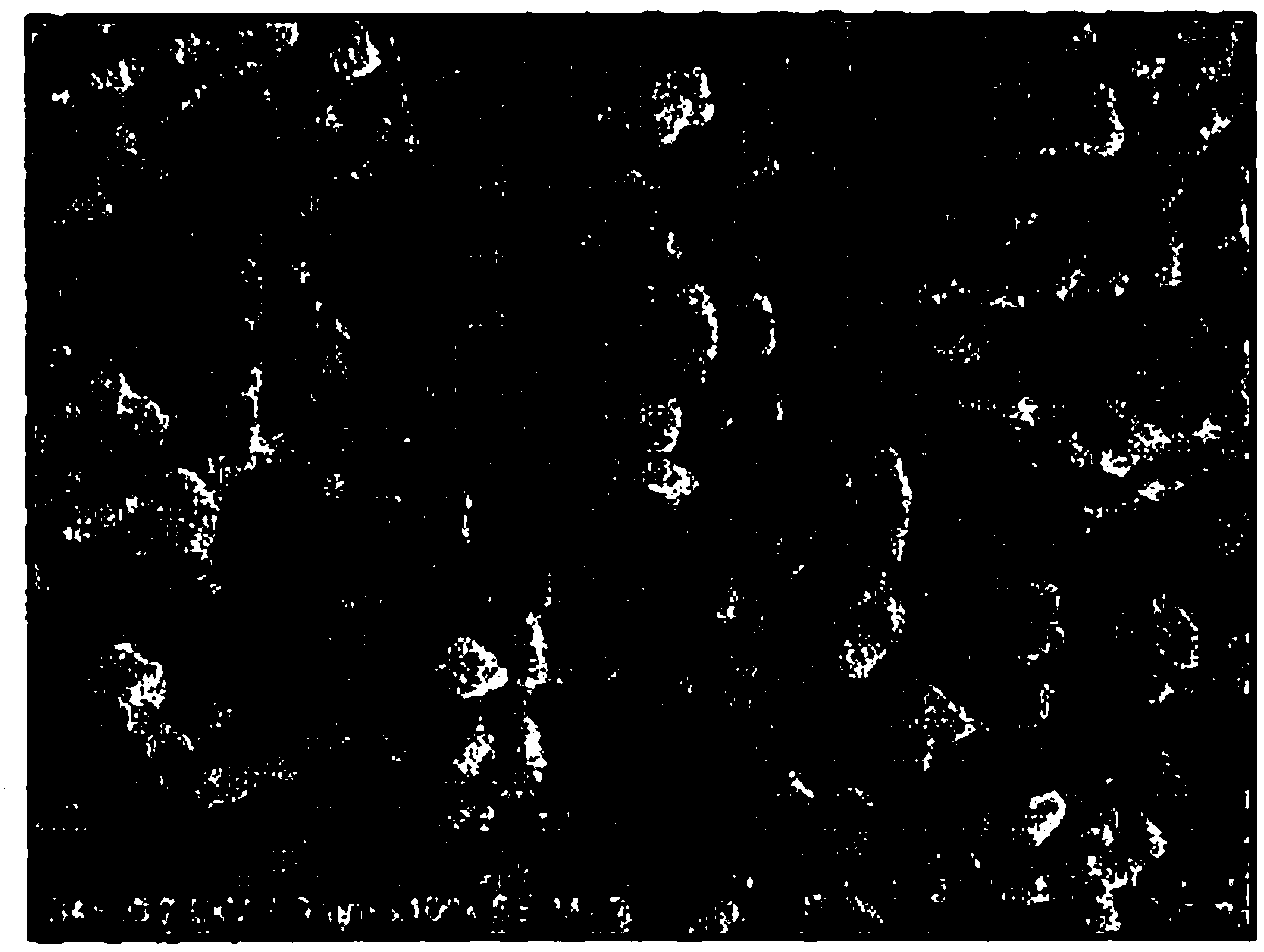

[0128] A mixture of 5 parts of C.I. Pigment Yellow 185 (manufactured by BASF Japan, Ltd. under the trade name "PALIOTOL YELLOW D1155") and 0.5 parts of compound (1) was mixed with 48 parts of polyester resin and 120 parts of ethyl acetate and ground with an ultrafine mill A pulverizer (manufactured by Mitsui Mining Co., Ltd.) was dispersed for 3 hours to obtain the pigment dispersion (1) of the present invention. The SEM photo of the pigment dispersion (1) is shown in figure 2 .

Embodiment 2

[0130] Pigment dispersion (2) was obtained by the same procedure as in Example 1, except that Compound (1) of Example 1 was changed to 1.5 parts of Compound (2) and ethyl acetate was changed to toluene.

Embodiment 3

[0132] Pigment dispersion (3) was obtained by the same procedure as in Example 1, except that Compound (1) of Example 1 was changed to 1.0 part of Compound (3) and ethyl acetate was changed to methyl ethyl ketone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com