A vacuum suction type screw extrusion solid-liquid separation system

A technology of screw extrusion and solid-liquid separation, which is applied in filtration separation, separation method, moving filter element filter, etc. It can solve the problems of inability to adjust the dry humidity of the material at the outlet, and the device occupies a large area, and achieve the best curing effect. , The effect of reducing the occupied area and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

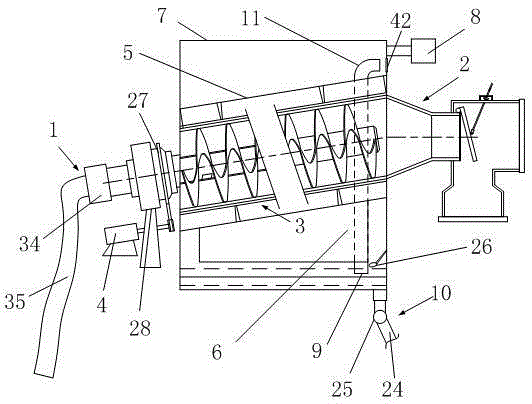

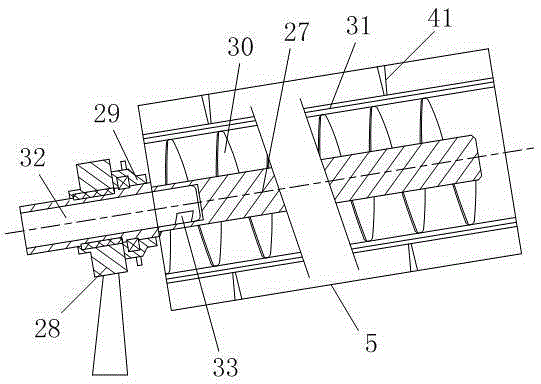

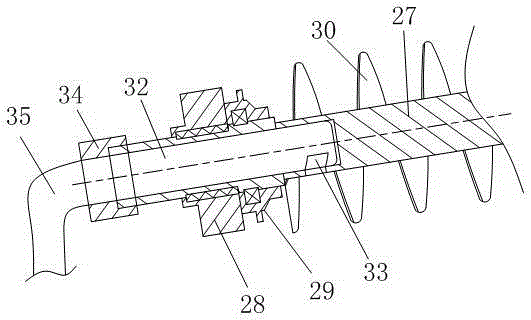

[0032] Such as Figure 1 to Figure 8 As shown, the vacuum suction type screw extrusion solid-liquid separation system includes a screw extrusion mechanism 3 connected with a continuous feeding mechanism 1 and a continuous solid removal mechanism 2, and a driving mechanism that provides rotational power for the screw extrusion mechanism 4. A sealed box body 5 that seals the screw extrusion mechanism and connects the continuous feeding mechanism and the continuous solid discharge mechanism with the outside; the screw extrusion mechanism is arranged obliquely, and its inlet height is lower than the outlet height; The bottom of the sealed box is provided with a collection tank 6 that communicates with the bottom of the sealed box and is used to collect liquid, and the sealed box is accommodated in a sealed water tank 7; The system provides a vacuum machine 8 with vacuum suction force; the bottom of the collection tank near the end of the continuous solid discharge mechanism is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com