A kind of corn peeling machine

A technology of peeling machine and corn, which is applied in the direction of grain husking, grain processing, application, etc. It can solve the problems of rigid setting, waste of manpower, and sticking of corn husks, etc., so as to achieve the effect of convenient use and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

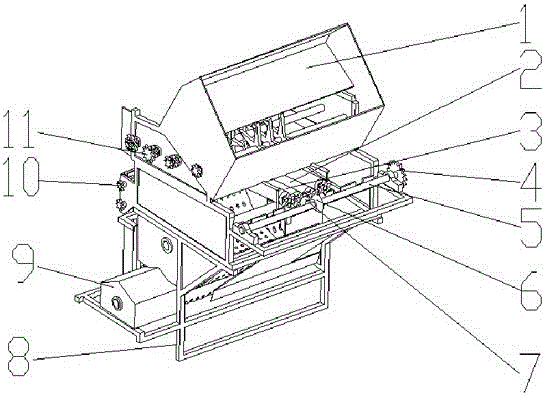

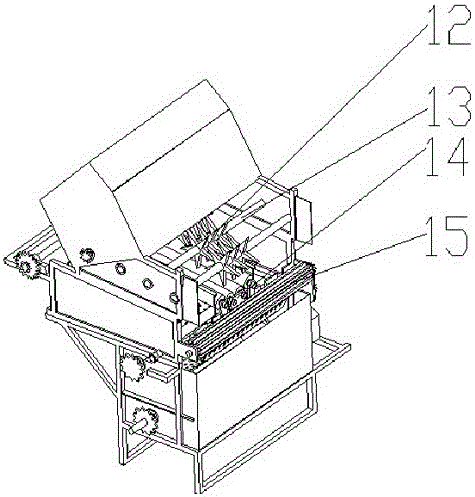

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

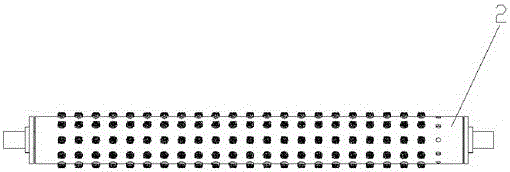

[0028] figure 1 , figure 2 The main structure of the corn peeling machine in the present invention is shown. In the corn peeling machine of the present invention, a peeling roller group is arranged side by side and tilted side by side above the frame 8, and the peeling roller group is arranged alternately by nail type peeling rollers 2 and spiral peeling rollers 3 Composition, nail type peeling roller 2 and spiral peeling roller 3 two ends are fixed on the frame 8 through bearing block 14, and the nail type peeling roller 2 of the higher end of the inclined peeling roller group and spiral peeling roller 3 are respectively equipped with gear 7 and Mutual meshing realizes the opposite rotation of the nail-type peeling roller 2 and the spiral peeling roller 3. The gear 7 is driven by the driving gear 6. The driving gear 6 is installed on the transmission shaft 5. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com