Superplastic Forming Method of LC4 Aluminum Alloy Ring with Complicated Section

A technology of aluminum alloy and ring parts, applied in metal rolling, metal processing equipment, etc., can solve the problems of superplastic forming that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

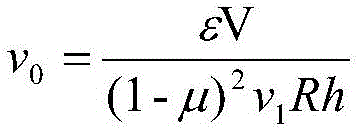

Image

Examples

specific Embodiment approach

[0023] To implement the superplastic forming method of the LC4 aluminum alloy ring with complex cross-section described in the present invention, it is necessary to provide equipment such as a high-temperature heating furnace, a press, a manipulator, and a ring rolling mill. The diameter of the main roll of the ring rolling mill is Φ860mm. The specific implementation is as follows:

[0024] The main chemical element content (percentage by weight) of LC4 aluminum alloy is: 0.40%-0.60% Si content, 0.40%-0.60% Fe content, 1.40%-2.00% Cu content, 0.20%-0.60% Mn content, 0.20%-0.60% Mn content, The Mg content is 1.80%-2.80%, the Cr content is 0.1%-0.25%, the Zn content is 5.00%-7.00%, and the balance is Al.

[0025] The superplastic forming process steps of LC4 aluminum alloy ring parts with complex cross-section are as follows:

[0026] Cut the LC4 aluminum alloy into rods according to certain specifications; in the salt bath, heat the LC4 aluminum alloy rods to 460±10°C for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com