Flexible and modular combined clamp for welding or machining locating of hydraulic hard tube

A modular and combined technology, applied in the field of mechanical processing, can solve the problems of low work efficiency, cumbersome and laborious process, etc., and achieve the effect of high production efficiency, simple structure and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

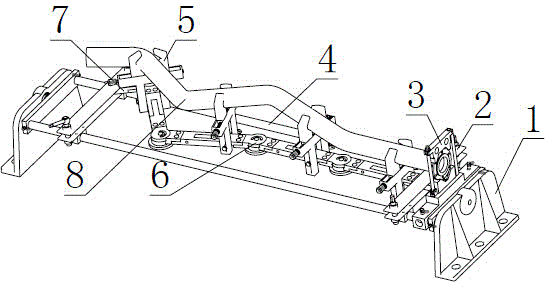

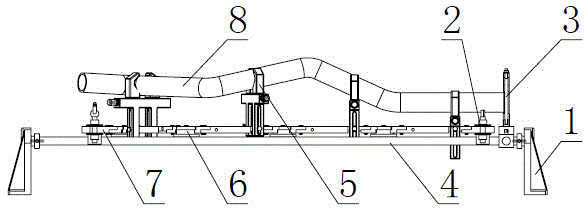

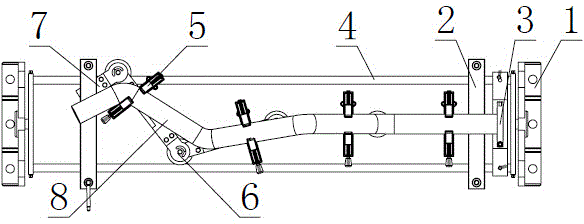

[0022] Refer to the attached figure 1 To attach Figure 10 The flexible, modular combined clamp for hydraulic hard pipe welding or processing positioning of the present invention will be described in detail below.

[0023] A flexible, modular combined fixture for hydraulic hard pipe welding or processing positioning, including a fixture body and a chuck device 5, the chuck device 5 is installed on the fixture body through a bending mechanism 6, and is characterized in that the The fixture body described above includes a base 1 and a guide rail 4. There are two bases 1 arranged opposite to each other on the left and right. Two parallel guide rails 4 are installed on the two bases 1. On the two parallel guide rails 4 Two sliding clamping mechanisms 4 are also provided, and four dry bending mechanisms 6 are arranged on the two sliding clamping mechanisms 4, and between two adjacent bending mechanisms 6 in the four bending mechanisms 6 The two ends of the four bending mechanisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com