Method for manufacturing light reflecting material mold with microprism array structure

A technology of array structure and reflective material, applied in optics, optical components, instruments, etc., can solve the problems of single triangular pyramid structure, affecting the recognition performance of reflective materials, etc., and achieve the effect of good reflective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The manufacturing method of the reflective material mold with the microprism array structure comprises the following steps:

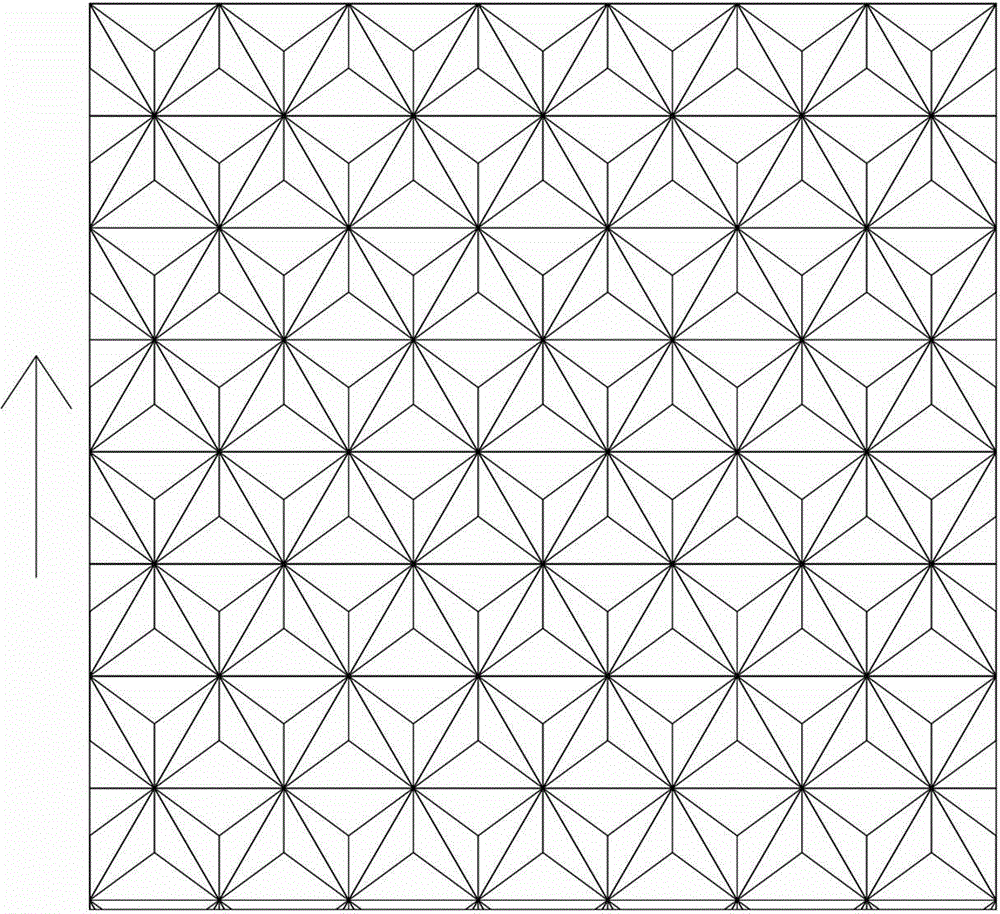

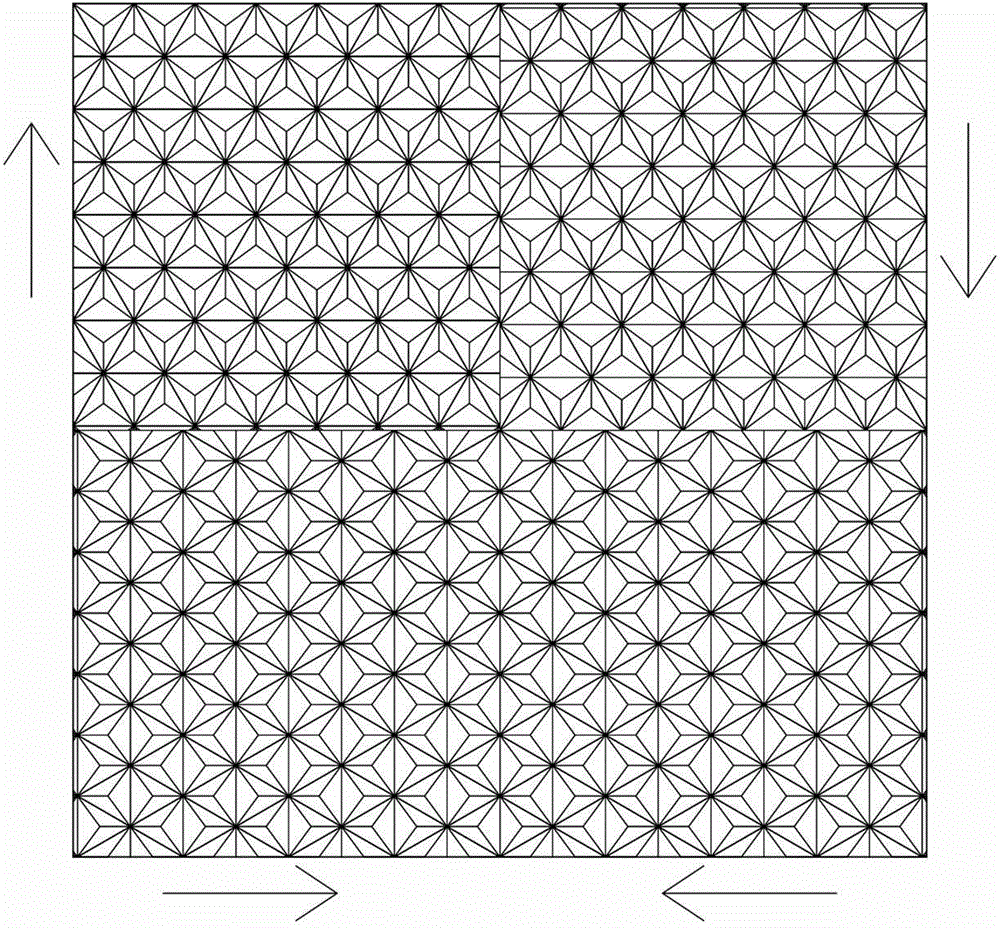

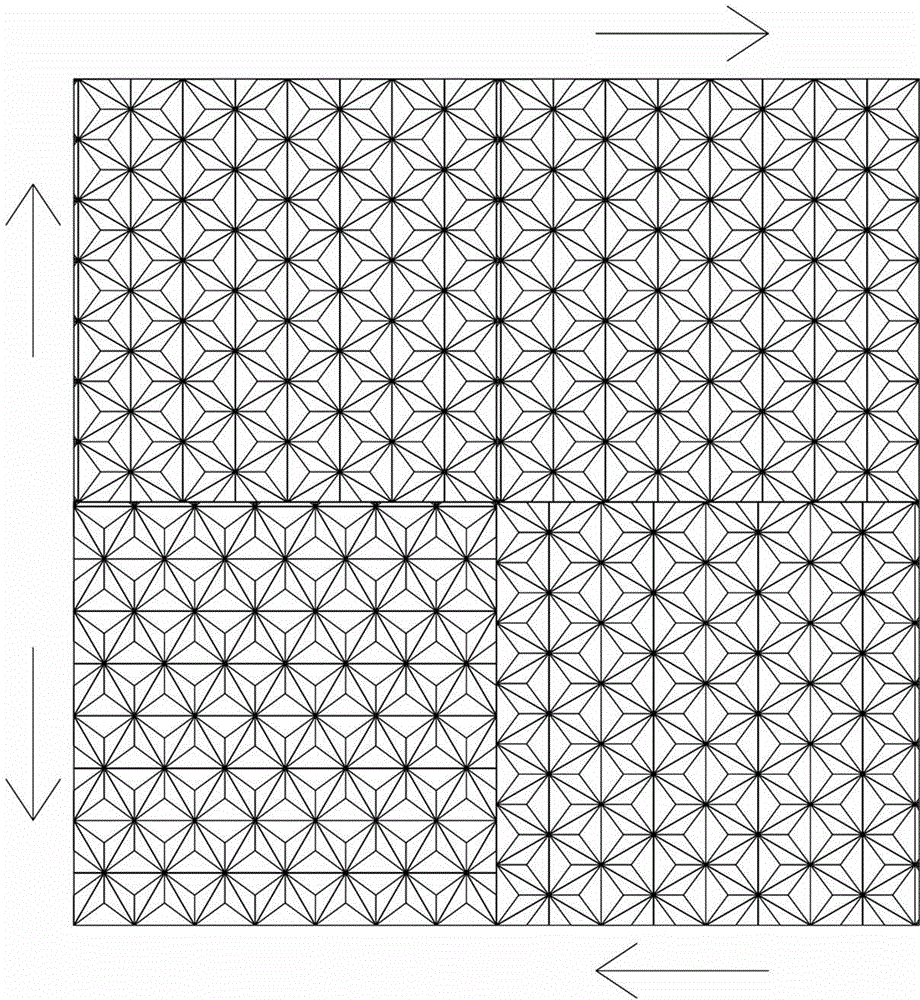

[0056] (a) Take a metal substrate, and engrave a raised microprism array structure on the metal substrate to form a metal template;

[0057] (b) Electroforming the metal template formed after the treatment in step (a) as a mother plate, using the mother plate as an electroforming cathode, copying a daughter plate made of nickel metal, and trimming the edges of the daughter plate ;

[0058] (c) cutting the sub-boards processed in step (b) to form multiple small boards;

[0059] (d) rotating and splicing the small plates obtained in step (c) to form large plates;

[0060] (e) Using the large plate obtained in step (d) as the cathode of electroforming to form a plurality of large plates through multiple copies, and splicing the large plates one or more times to form a larger-sized metal nickel template, The production of the reflective material m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com