Built-in steel pipe mitre elbow discharging lofting device

A shrimp elbow, built-in technology, applied in workshop equipment, manufacturing tools, etc., can solve problems such as duplication of work and low efficiency, and achieve the effect of eliminating complicated calculations, avoiding multiple trimming, and achieving high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

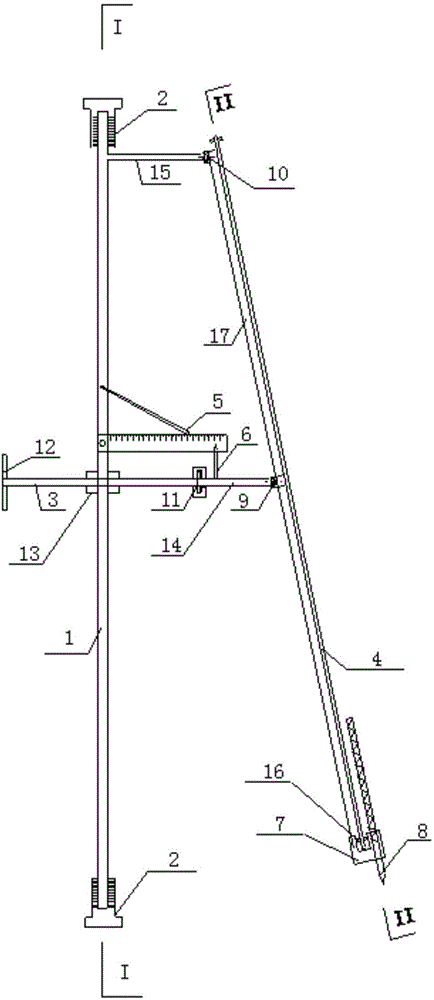

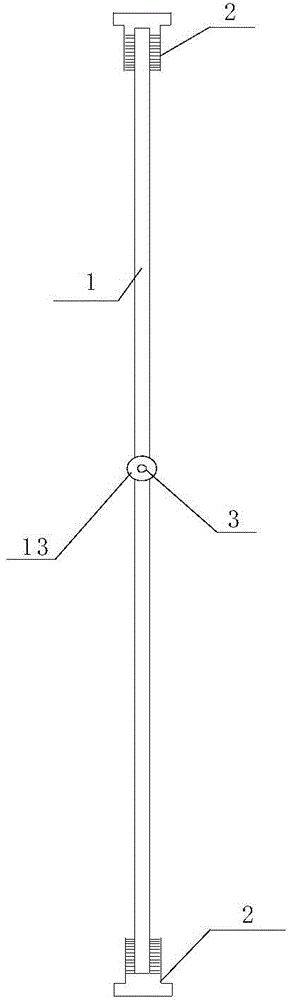

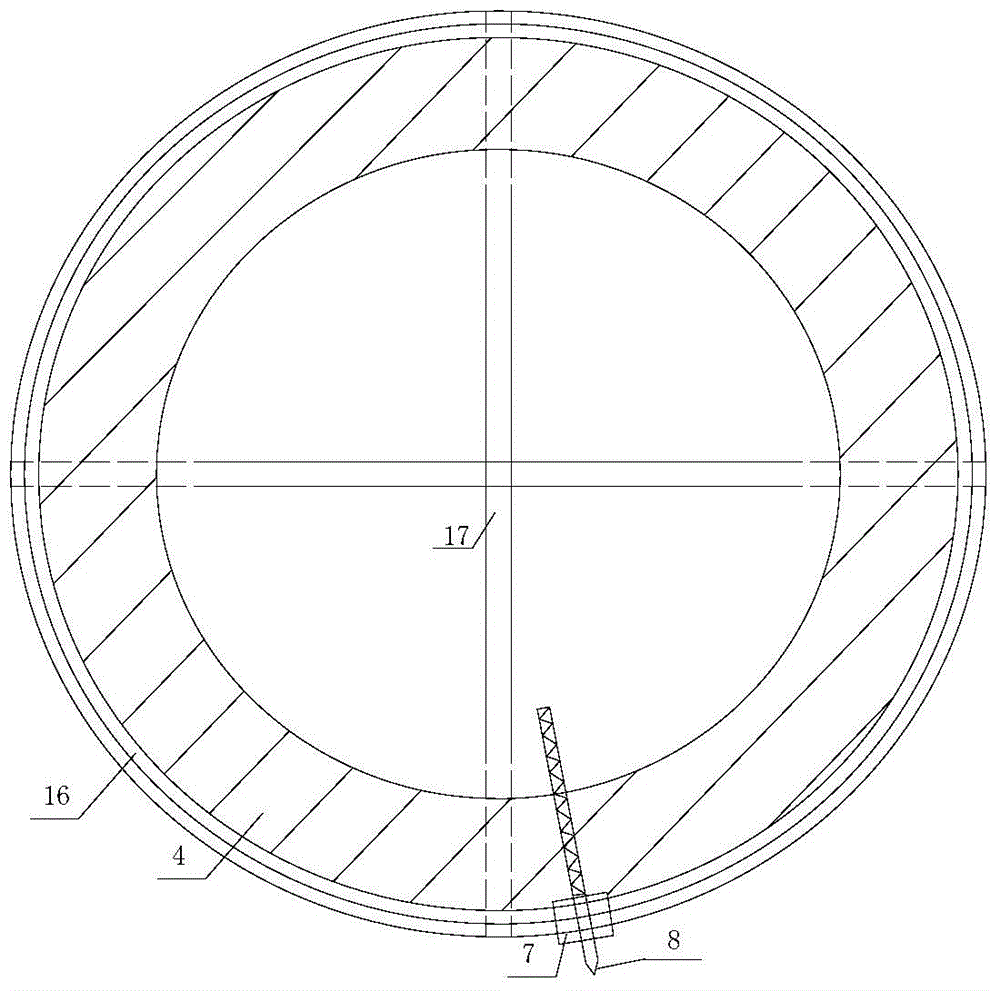

[0024] Such as figure 1 The built-in steel pipe elbow blanking and lofting device shown in the present invention includes a vertical rod 1, an adjustment support 2, a screw rod 3, a ring rod 4, an angle scale 5, a pointer 6, an electric walking device 7, an elastic drawing needle 8, First movable bushing 9, second movable bushing 10, movable collar 11, rotary handle 12, internally threaded bushing 13, connecting rod 14, cross bar 15, guide rail 16 and ring bar cross 17. One side of the top of the vertical rod 1 is provided with a cross bar 15, and one end of the cross rod 15 is flexibly connected with the top of the ring rod 4; An angle scale 5 is arranged parallel to the connecting rod 14 on the vertical rod 1, and a pointer 6 is arranged on the upper part of the connecting rod 14. Connection; the bottom of the ring rod 4 is provided with an elastic drawing pin 8 . According to the different sizes of steel pipes used, adjustable supports 2 of different sizes are movably arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com