Multilevel cleaning device and multilevel cleaning method for various waste plastics

A cleaning device and waste plastic technology, applied in the field of waste plastic recycling, can solve the problems of high water consumption, low efficiency, incomplete separation, etc., and achieve the effects of saving electricity, water, and reducing material transportation links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

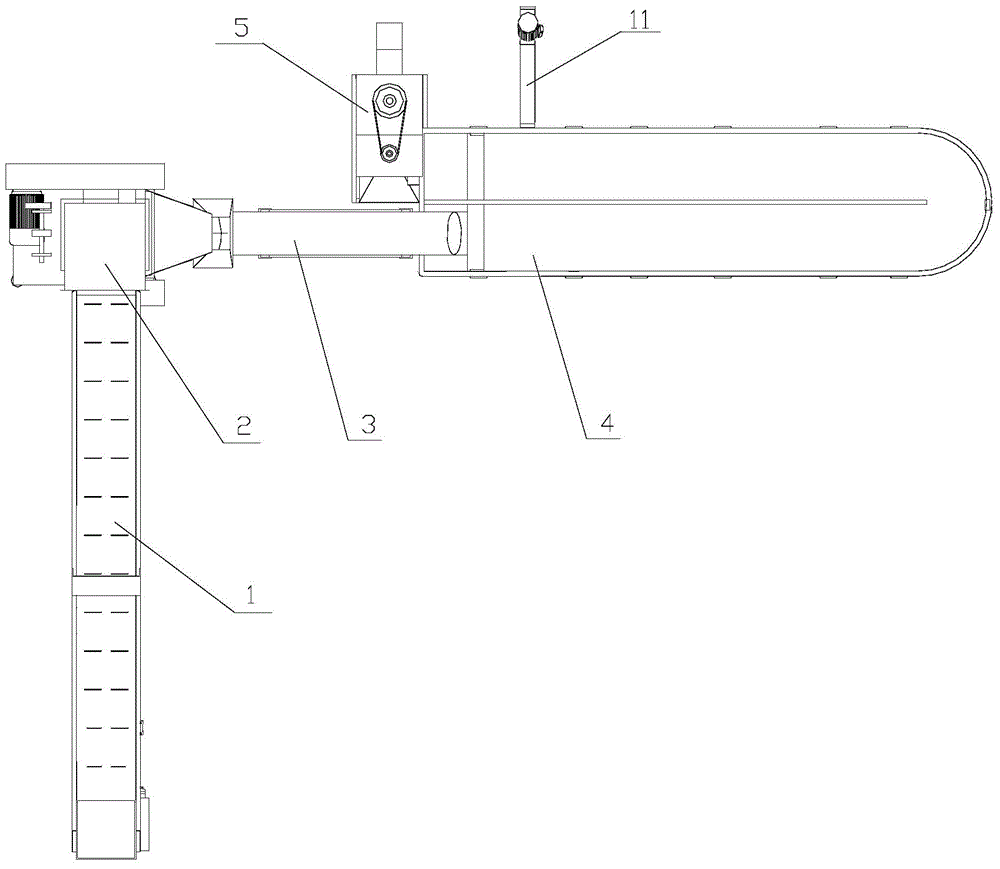

[0042] This embodiment is a multi-stage cleaning device suitable for various waste plastics, mainly used for cleaning rigid waste plastic fragments. Such as figure 1 As shown, the multi-stage cleaning device includes a belt conveyor 1, a crusher 2, a washing cage 3, a rinsing tank 4, and a terminal dehydrator 5 connected in sequence. A first-stage circulating water treatment pool is provided under the washing cage, and the first-stage circulation The water treatment pool is respectively connected to the feed end of the crusher and the washing cage through the first-stage return pipe, and the second-stage circulating water treatment pool is installed under the terminal dehydrator, and the second-stage circulating water treatment pool is connected to the The rinsing tank is connected; the first-stage circulating water treatment pool and the second-stage circulating water treatment pool are set independently of each other.

[0043] Among them, according to the needs of the actua...

Embodiment 2

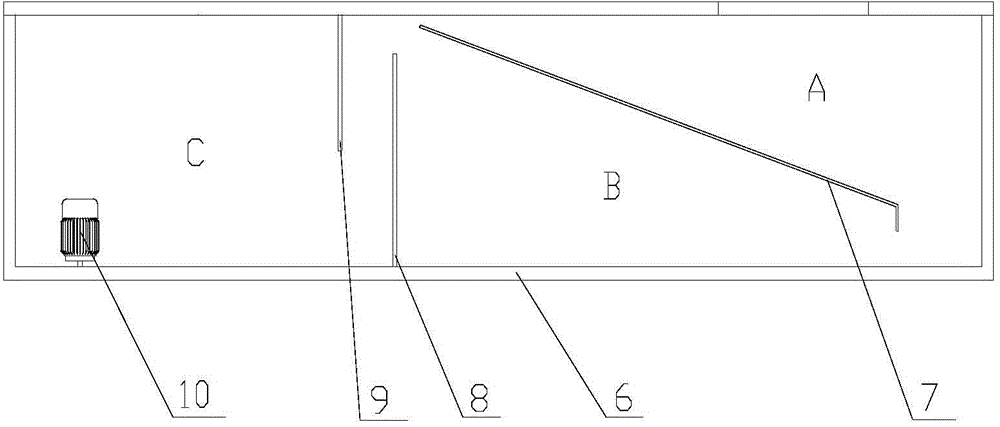

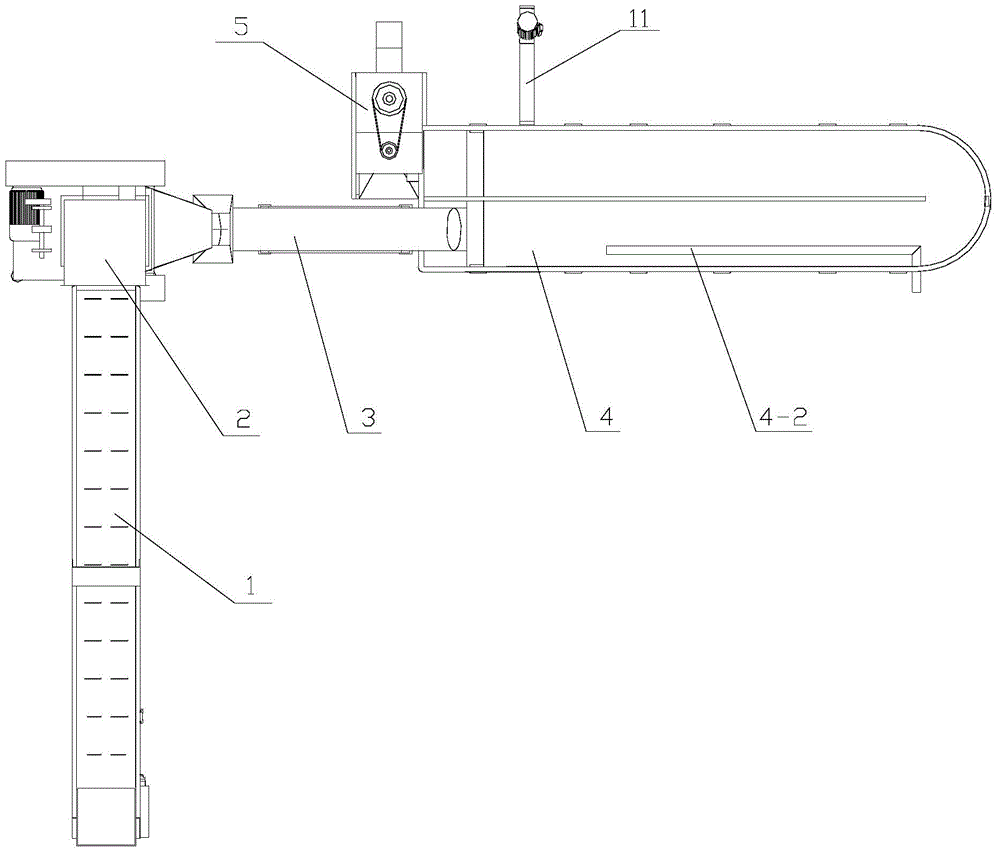

[0057] This embodiment is a multi-stage cleaning device suitable for various waste plastics, mainly used for cleaning flexible waste plastic fragments, such as image 3 Shown, compared with embodiment 1, its difference has the following two points:

[0058] 1. In the washing cage, the push rod adopts a spiral push rod, and the top of the outer cylinder is set as an open structure. There is a nozzle above the opening. During the transportation of waste plastic fragments, the waste plastic fragments pass through the cleaning water from the feed end. To clean, spray cleaning water into the outer cylinder through the nozzle. At this time, the waste plastic fragments can be cleaned more fully. After cleaning, all the cleaning water is discharged from the hole at the bottom of the outer cylinder to the circulating water treatment pool.

[0059] 2. The rinsing tank includes the tank body and the air distribution pipe, such as Figure 4 As shown, the air distribution pipe 4-2 is arra...

Embodiment 3

[0072] This embodiment is a multi-stage cleaning device suitable for various waste plastics, and is mainly used for cleaning flexible waste plastic fragments. Compared with Example 2, its difference is that, as Figure 5 As shown, there is also a first-stage dehydrator 12 between the washing cage and the rinsing tank, and the first-stage dehydrator is also located above the first-stage circulating water treatment pool, and the water outlet of the first-stage dehydrator is connected to the first-stage circulation The water treatment pool is connected. The addition of a first-stage dehydrator can completely separate the cleaning water contained in the waste plastic fragments before they enter the rinsing tank, minimize the amount of cleaning water entering the rinsing tank, and maintain the independence between the two stages of cleaning to prevent cleaning Water contaminates the fluid medium in the rinse tank.

[0073] The present embodiment realizes a kind of cleaning method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com