Foaming mold manufacturing method for avoiding generation of fash due to deformation

A manufacturing method and foaming mold technology, which is applied in the field of EPS foaming mold manufacturing to offset the deformation of the parting surface, can solve the problems of cumbersome anti-deformation manufacturing process, and achieve the effects of offsetting mold deformation and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] A method for manufacturing a foaming mold that solves deformation and produces seams, comprising the steps of:

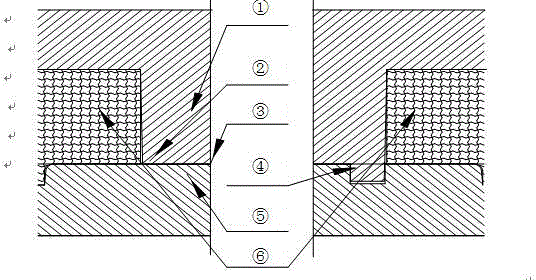

[0018] After the mold is designed, a 3mm deep and 40mm wide groove ④ is designed on the boundary of the molding surface of the punch ⑤, and a corresponding size convex platform is designed corresponding to the boundary of the molding surface of the concave mold ①;

[0019] Cast blanks according to design drawings;

[0020] by design Figure 1 Complete the fine and rough machining of the mold for the first time, and finally release the pressure plate to limit the circumference of the mold and offset the deformation groove along the circumference; polish the surface of the mold;

[0021] Detect the processing size of each component;

[0022] Assemble the product according to the design assembly drawing

[0023] On-site assembly: docking with equipment, mass production.

example 2

[0025] A method for manufacturing a foaming mold that solves deformation and produces seams, comprising the steps of:

[0026] After the mold is designed, a 4mm deep and 50mm wide groove ④ is designed on the boundary of the molding surface of the punch ⑤, and a corresponding size convex platform is designed corresponding to the boundary of the molding surface of the concave mold ①;

[0027] Cast blanks according to design drawings;

[0028] by design Figure 1 Complete the fine and rough machining of the mold for the first time, and finally release the pressure plate to limit the circumference of the mold and offset the deformation groove along the circumference; polish the surface of the mold;

[0029] Detect the processing size of each component;

[0030] Assemble the product according to the design assembly drawing

[0031] On-site assembly: docking with equipment, mass production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com