Processing method of anti-counterfeiting printed products

A processing method and printed matter technology, applied to the printing, printing process, and printing of special varieties of printed matter, can solve the problems of easy loss of security and counterfeiting of anti-counterfeiting measures, and achieve the effect of high anti-counterfeiting security, effective anti-counterfeiting means, and complex design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] A kind of processing method of anti-counterfeit printed matter of the present invention, comprises the following steps:

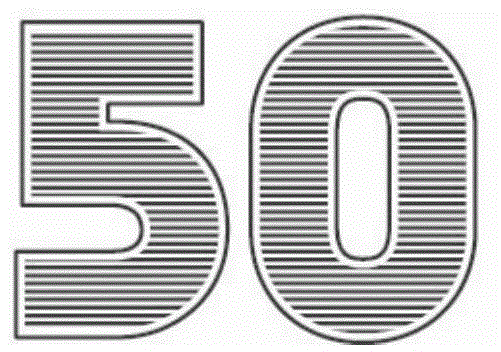

[0022] Step 1. Use optical color-changing ink to print the base pattern on the substrate. The printed base pattern can be printed by screen printing, gravure printing or embossing, such as figure 1 As shown, the screen-printed base pattern, 100% of the base pattern area is covered by ink, figure 1 The color shown is the first color of the optically variable ink when viewed directly.

[0023] Step 2, design the embossed concave-convex pattern of the intaglio and letterpress layout, the outline of the embossed concave-convex pattern is smaller than the outline of the above-mentioned base pattern, and the outline of the embossed concave-convex pattern is filled with geometric element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com