Aquaculture wastewater treatment process

A breeding sewage and process technology, which is applied in animal husbandry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Deal with problems such as unsatisfactory effects, achieve the effect of improving the quality of agricultural products, reducing investment and operating costs, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] Example 1

[0016] A process for treating aquaculture sewage, which includes the following steps:

[0017] Preparation of bacterial agent: mix the mixed bacterial liquid and sawdust at a weight ratio of 1:1, stir evenly, and then dry at 4°C at low temperature, and control the moisture content at 8% after drying to obtain; the mixed bacterial liquid has the following volume Mixture of raw material bacteria: 10 parts of Bacillus pumilus, 8 parts of Thiobacillus denitrificans, 6 parts of Alcaligenes faecalis, 5 parts of Pseudomonas aeruginosa, 2 parts of Bacillus cereus, 2 parts of Sphingosine Parts and 1 part of Rhodococcus; the concentration of the above-mentioned raw material bacteria is controlled at 1×10 8 Pcs / ml.

[0018] Impurity removal and sedimentation: The farming sewage passes through the grille and the muddy water separator in turn to remove solid materials such as pig manure and collect the solid materials, which can be used as organic fertilizer; then the sewage e...

Example Embodiment

[0021] Example 2

[0022] Take the pig farming wastewater of our company as an example to test the wastewater treatment effect of Example 1. As long as all indicators meet the ideal discharge standard, the testing indicators of farming wastewater are shown in Table 1:

[0023] Table 1 Parameters before and after sewage treatment

[0024] project name

Example Embodiment

[0025] Example 3

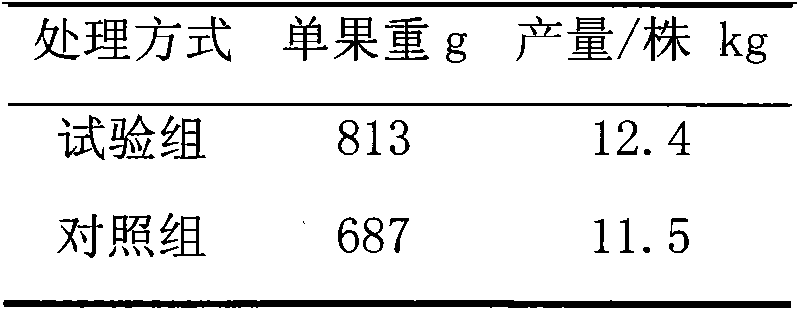

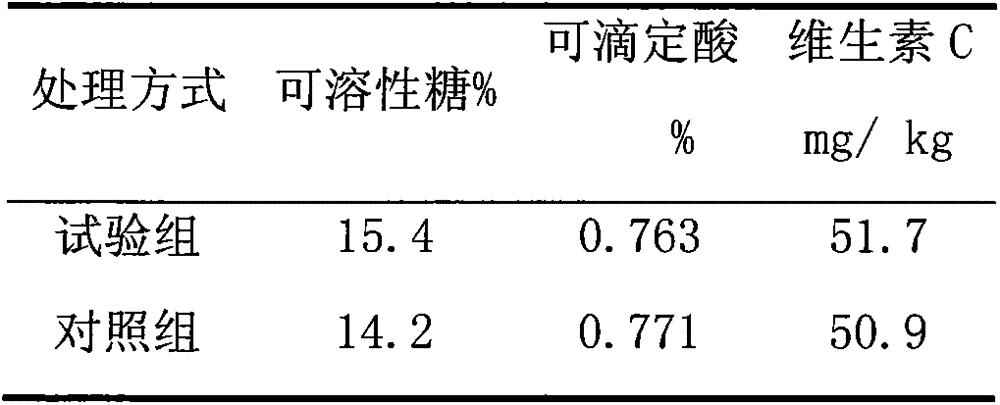

[0026] The influence of the bacterial fertilizer prepared in Example 1 of the present invention on the yield and quality of grapes. The test grapes were 3-year-old Kyoho, and ordinary soybean meal organic fertilizer was used as a control. Example 1 of the present invention was the test group; the application rate was 2 kg / plant per plant of the present invention and 2 kg / plant of ordinary organic fertilizer under routine management. The results are shown in Tables 2 and 3. The use of the present invention can increase the sugar-acid ratio and the degree of coloring of Kyoho grapes, and the fruit flavor is better; the use of the present invention also significantly increases the weight of individual grapes.

[0027] Table 2 The influence of the present invention on the yield of Kyoho grapes

[0028]

[0029] Table 3 The influence of the present invention on the quality of Kyoho grapes

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com