Improved structure of windless area of spinning equipment

A windless zone and spinning technology, which is applied in the transformation of chemical fiber equipment and the improved structure of the windless zone of spinning equipment, can solve problems such as inability to adjust and disassemble, so as to ensure production quality, meet process requirements, and realize The effect of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

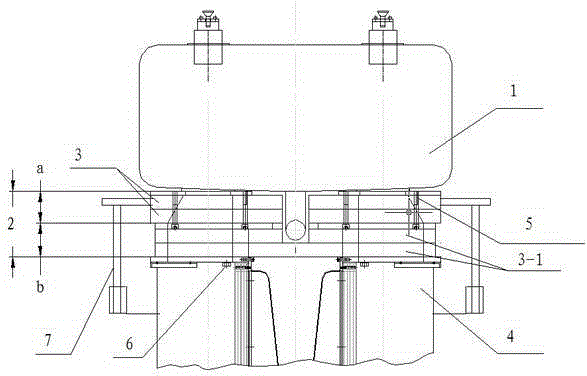

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] The improved structure of the windless area of spinning equipment includes a spinning box 1 and a windless area 2. The windless area is divided into an upper fixed area a and an adjustable area b connected to it, and a partition set in the windless area. Heat plate, side blowing device 4, fixed section connection screw 5, side blowing connection screw 6, the heat insulation board arranged in the windless area is also specifically divided into the heat insulation board 3 of the fixed area and the heat insulation board of the adjustable area Plate 3-1; specific connection method: the two ends of the lower end of the spinning box 1 are respectively connected to the heat insulation board 3 in the fixed area through two fixed section connecting screws 5, and the heat insulation board 3 in the fixed area is set on the heat insulation board in the adjustable area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com