Improved phosphor deposition system for leds

A phosphor layer and transparent conductor technology, which is applied in the field of color-changing light-emitting device packaging, can solve the problems of reducing the range of color adjustability between color endpoints, and achieve the effects of low cost, high mechanical robustness, and large thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

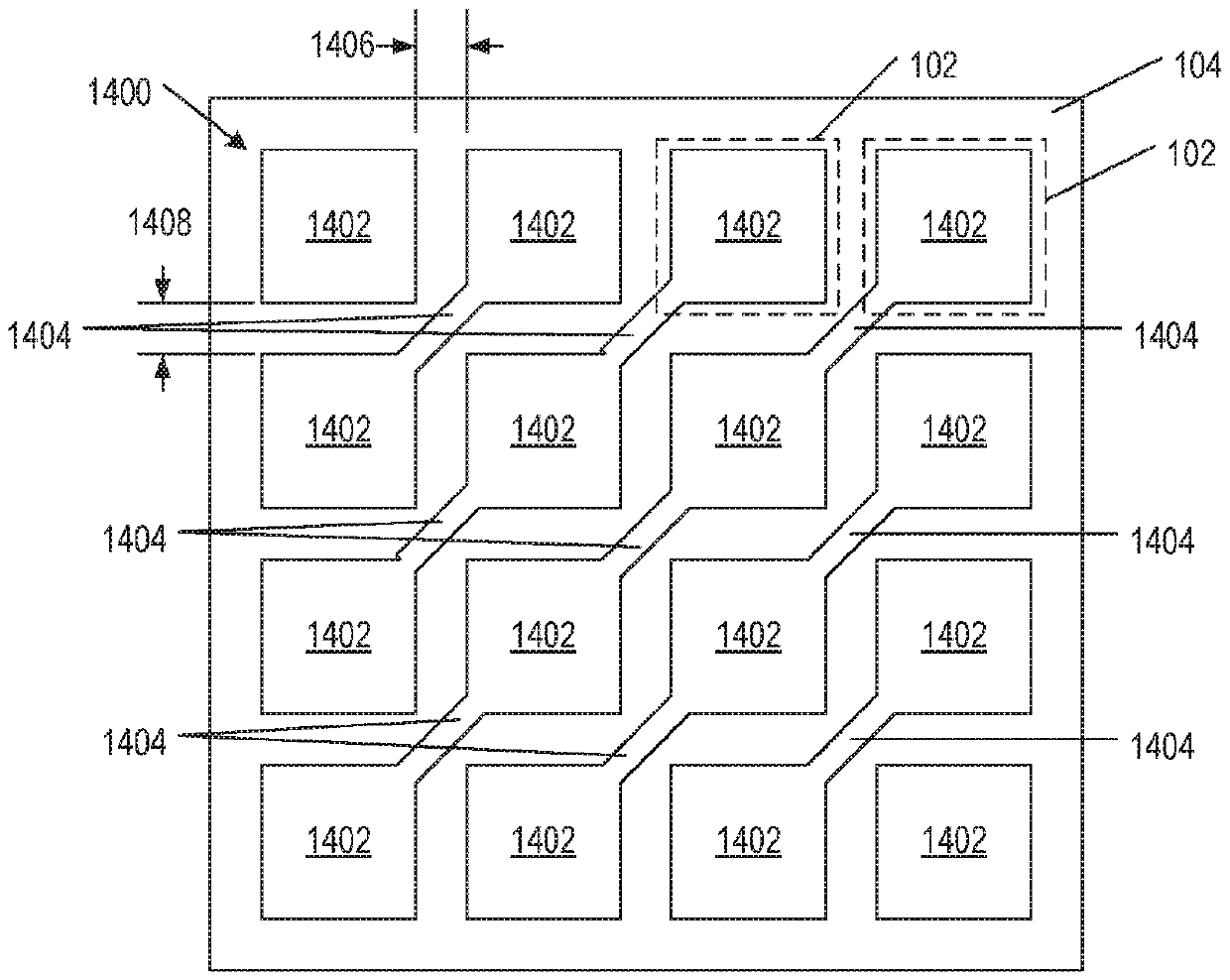

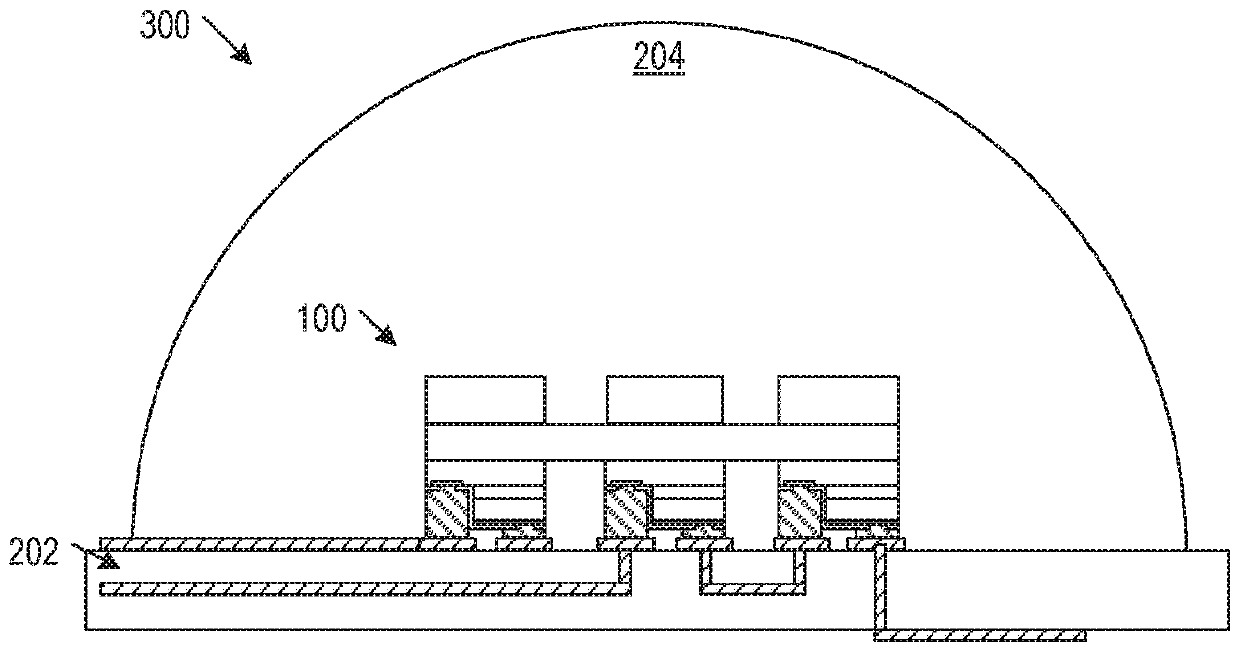

[0077] Picture 1-1 is a top view of a light emitting diode (LED) die 100 in some examples of the present disclosure. LED die 100 may be a segmented or multi-junction LED die. LED die 100 includes an array of junctions 102-1, 102-2, . ). The array of junctions 102 in LED die 100 is not limited to any size or shape. A trench 106 down to growth substrate 104 surrounds junction 102 such that they are fully electrically isolated from each other. Trenches 106 may be formed by wet etching, dry etching, mechanical sawing, laser scribing, or another suitable technique.

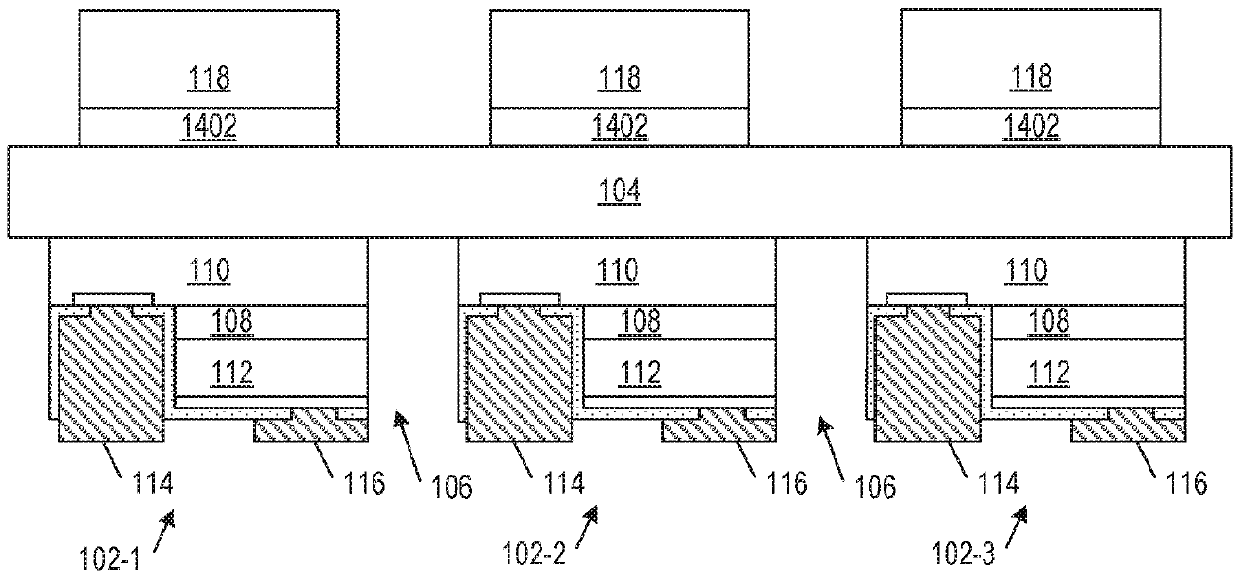

[0078] Figure 1-2 is a cross-sectional view of an LED die 100 in some examples of the present disclosure. Each junction 102 has a semiconductor structure including an active region 108 between an n-type semiconductor layer 110 and a p-type semiconductor layer 112 . Each junction 102 has a cathode 114 coupled to its n-type semiconductor layer 110 through an ohmic p-contact through an opening in the insulator (d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com