Method for producing elastic jacquard spacer fabric by a double-needle-bar warp knitting machine

A double-needle bed warp knitting machine and spacer fabric technology, which is applied in the field of fabric textiles, can solve the problems of small deformation capacity, non-compact structure, and limited jacquard function, and achieve the effect of good elasticity and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of method for producing elastic single-color jacquard spacer fabric on a 7-comb double-needle bed warp knitting machine is as follows:

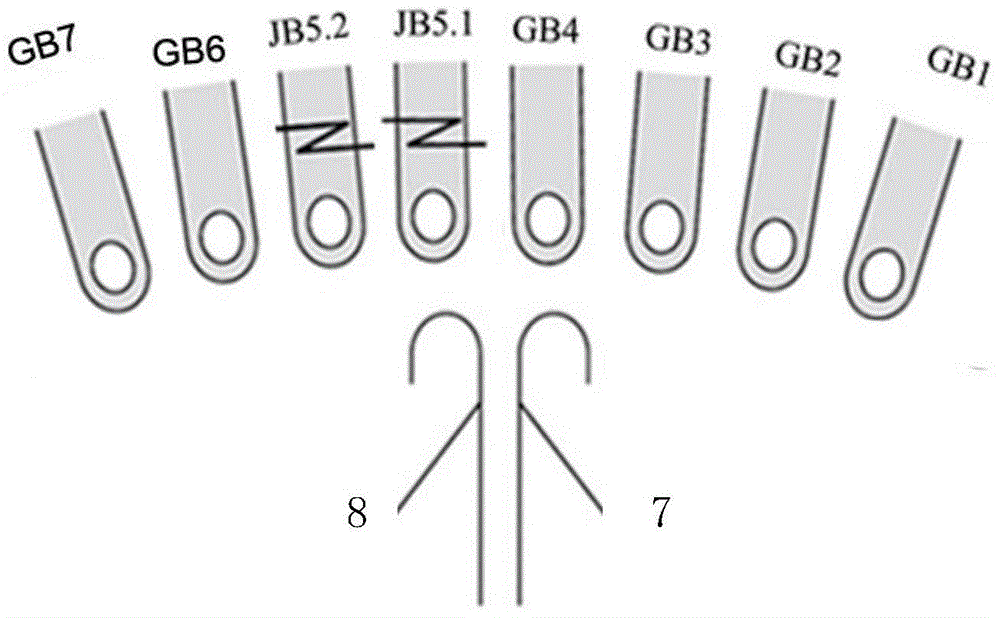

[0035] (1) Bar configuration: such as figure 1 As shown, GB1 and GB7 are elastic bars, GB2, GB3, and GB6 are ground bars, JB5.1 and JB5.2 are Jacquard bars, and GB4 is a spacer yarn guide bar, such as figure 1 shown;

[0036] (2) Configuration gauge: the spacer fabric is used for bra fabrics, and the distance between the front needle bed 7 and the rear needle bed 8 is set to be 2.5mm;

[0037] (3) Yarn preparation: the structure of the spacer fabric surface (non-jacquard surface surface) is an elastic plain weave structure, and 30dtex polyester monofilament, 78dtex nylon filament, and 44dtex spandex yarn are selected;

[0038] (4) CAD design: through CAD software, design a single-color jacquard surface, such as figure 2 shown in;

[0039] (5) Upper machine weaving: Elastic bars GB1 and GB7 are fully penetrated ...

Embodiment 2

[0043] Embodiment 2 A kind of method for producing elastic two-color jacquard spacer fabric on a double-needle bar warp knitting machine with 8 combs, its steps are:

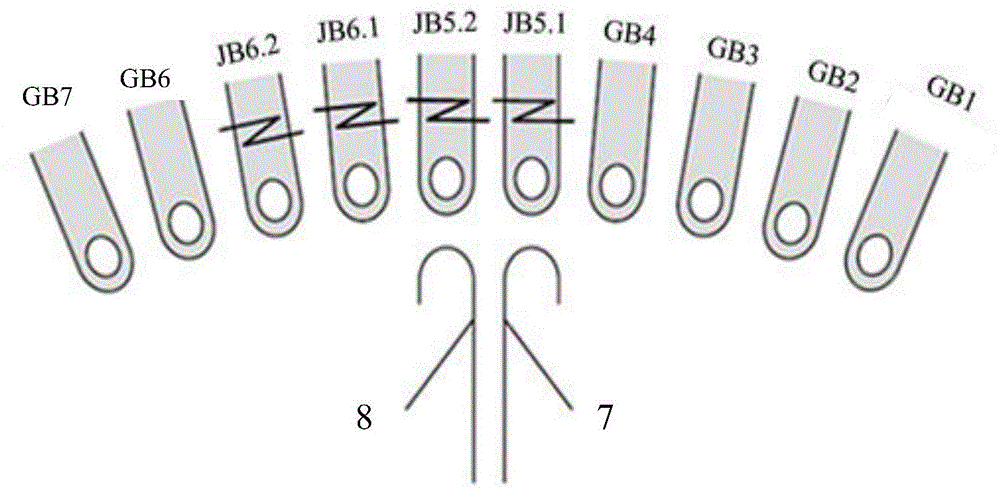

[0044] (1) Bar configuration: such as image 3 As shown, GB1 and GB7 are elastic bars, GB2, GB3, and GB6 are ground bars, JB5.1, JB5.2, JB6.1, and JB6.2 are Jacquard bars, and GB4 is spacer yarn guide bars ,like image 3 shown;

[0045] (2) Configure the gauge: the spacer fabric is used for the shoe material fabric, and the distance between the front needle bed 7 and the rear needle bed 8 is set to 3.5mm;

[0046] (3) Yarn preparation: the structure of the spacer fabric surface (non-jacquard surface) is an elastic plain weave structure, and 30dtex polyester monofilament, 78dtex nylon filament, 78dtex A-color nylon filament, and 78dtex B-color nylon filament are selected. , 44dtex spandex yarn;

[0047] (4) CAD design: through CAD software, design a two-color jacquard surface, such as Figure 4 shown;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com