Tool-type steel formwork and its construction method for the facade cushion layer around the pile foundation cap

A tool-type, cushioning technology, applied in infrastructure engineering, construction, etc., can solve the problems of many construction procedures, many types of materials, and high transportation costs, and achieve the effect of simple processes, single types of materials, and increased construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

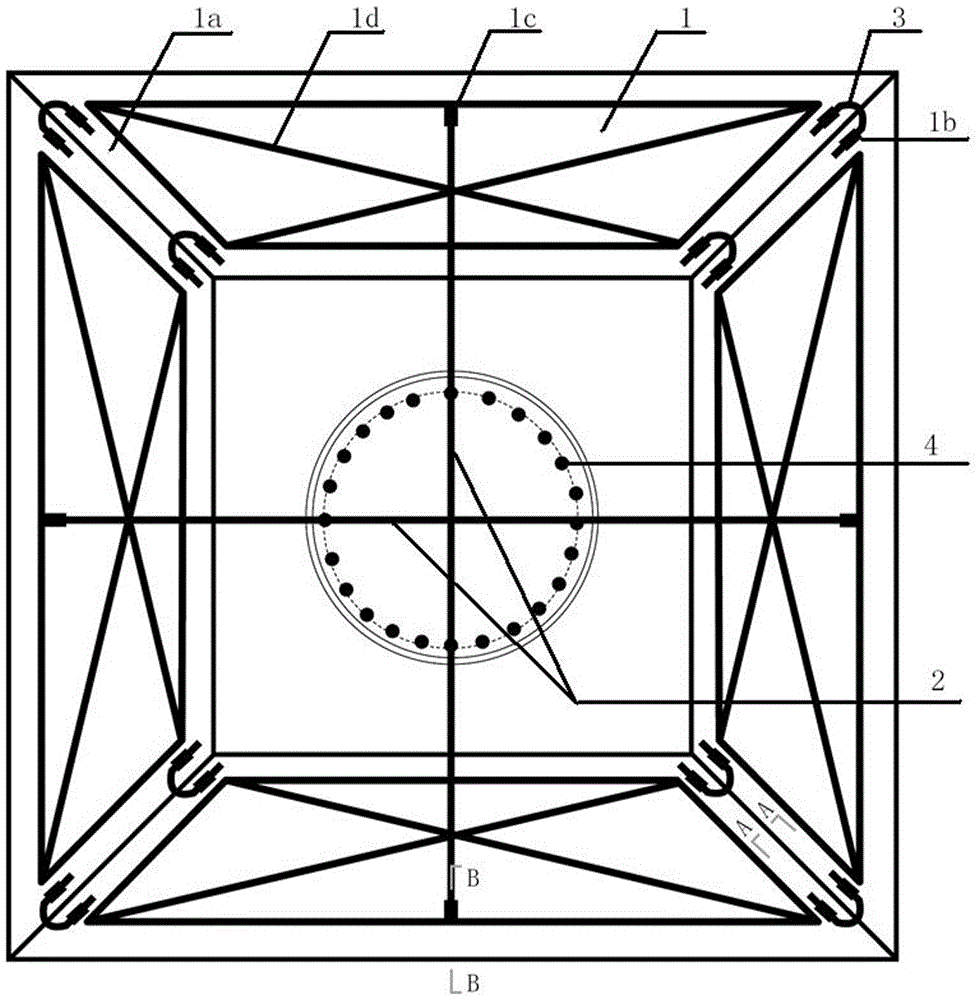

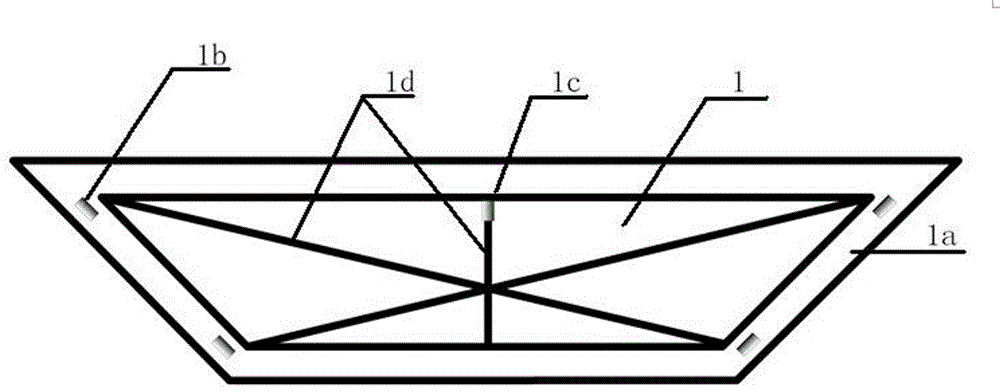

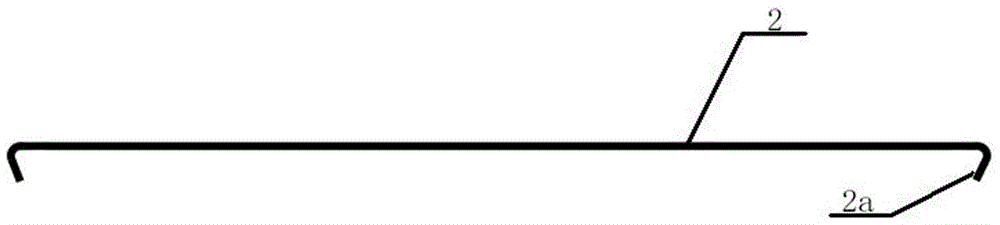

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the tool-type steel formwork of the facade cushion around the pile foundation cap includes four trapezoidal steel formworks 1 enclosed by four pieces of trapezoidal steel formwork 1 around the pile foundation 4, forming a square cone with a wide top and a narrow bottom. The supporting piece 2 between the trapezoidal steel formworks 1, and the U-shaped clip-type connector 3 connecting two adjacent steel formworks. The side of the steel formwork has an outwardly turned flange 1a, and the U-shaped clip-type connector 3 is clamped on the flanges of two adjacent steel formworks to closely connect the two adjacent steel formworks. A reinforcing rib 1d is provided on the steel formwork. Reinforcing rib 1d is welded on the periphery of the steel formwork, in the middle position between the upper bottom edge and the lower bottom edge, and at the diagonal position, so as to increase the rigidity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com