Floor heating floor

A floor and floor heating technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of unsolved water and floor heating products, and achieve the effects of light weight, simple installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

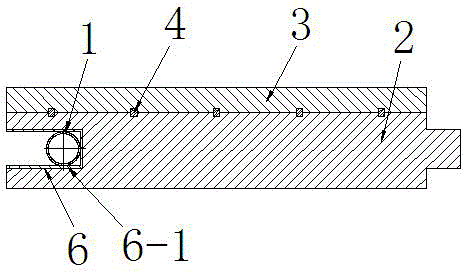

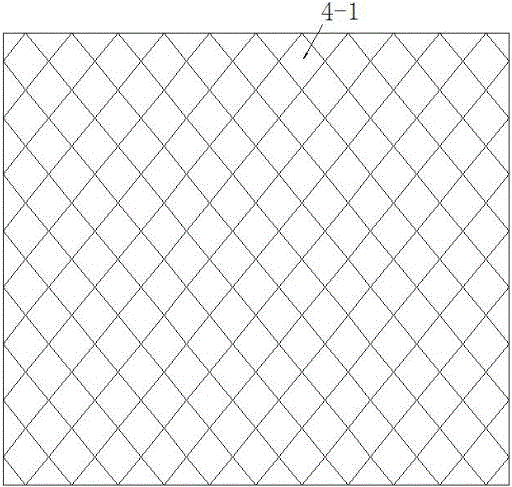

[0035] Embodiment 1: see attached figure 1 , attached figure 2, a floor heating floor, comprising a base material layer 2 at the bottom, a decorative panel layer 3 bonded to the top of the base material layer 2 by wood glue, and a metal mesh layer 4, the metal mesh layer 4 is placed between the base material layer 2 and the Between the decorative panel layers 3 and embedded in the connected base material layer 2 and the decorative panel layer 3 by hot pressing to form an integral structure, the thickness of the metal mesh layer 4 is less than or equal to the compression deformation of the connected base material layer and the decorative panel layer quantity. A tenon joint groove 6 is provided at the end of the floor, and a heat conduction surface 6-1 is provided on the inner wall of the tenon joint groove 6. The heat conduction surface 6-1 is made of a metal material aluminum alloy, and a hot water pipe is accommodated in the tenon joint groove 6-1. 1.

[0036] After hot r...

Embodiment 2

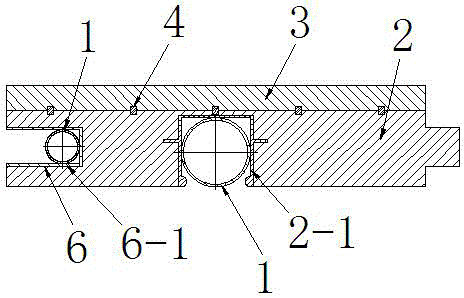

[0040] Embodiment 2: see attached figure 2 , attached image 3 , a floor heating floor, comprising a base material layer 2 arranged at the bottom, a decorative panel layer 3 bonded by wood glue on the upper part of the base material layer 2, and a metal mesh layer 4, between the adjacent base material layer 2 and the decorative panel A metal mesh layer 4 is arranged between the layers 3, and the metal mesh layer 4 located between the adjacent substrate layer 2 and the decorative panel layer 3 is embedded between the connected substrate layer 2 and the decorative panel layer 3 by hot pressing . The thickness of the metal mesh layer 4 is less than or equal to the compression deformation of the connected substrate layer and decorative panel layer. A tenon joint groove 6 is provided at the end of the floor, and a heat conduction surface 6-1 is provided on the inner wall of the tenon joint groove 6. The heat conduction surface 6-1 is made of a metal material aluminum alloy, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com