Method for improving straight shear bearing force of reinforced concrete member

A reinforced concrete, bearing capacity technology, applied in building construction, building maintenance, construction, etc., can solve the problem of no direct shear reinforcement found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

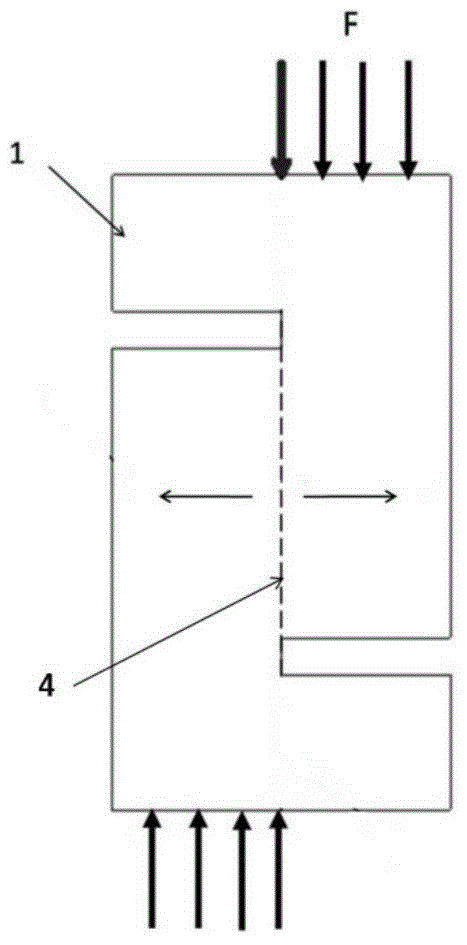

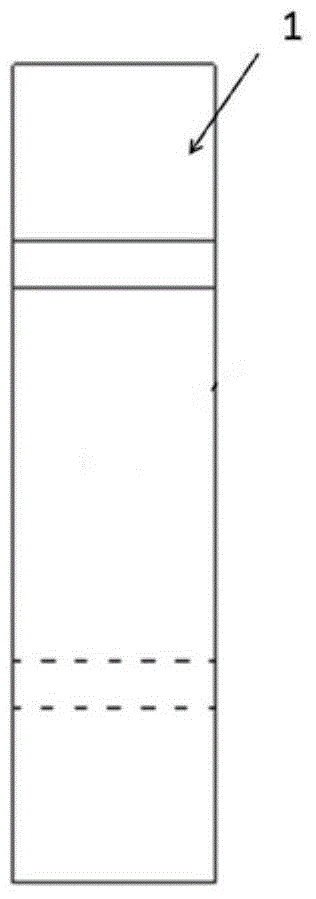

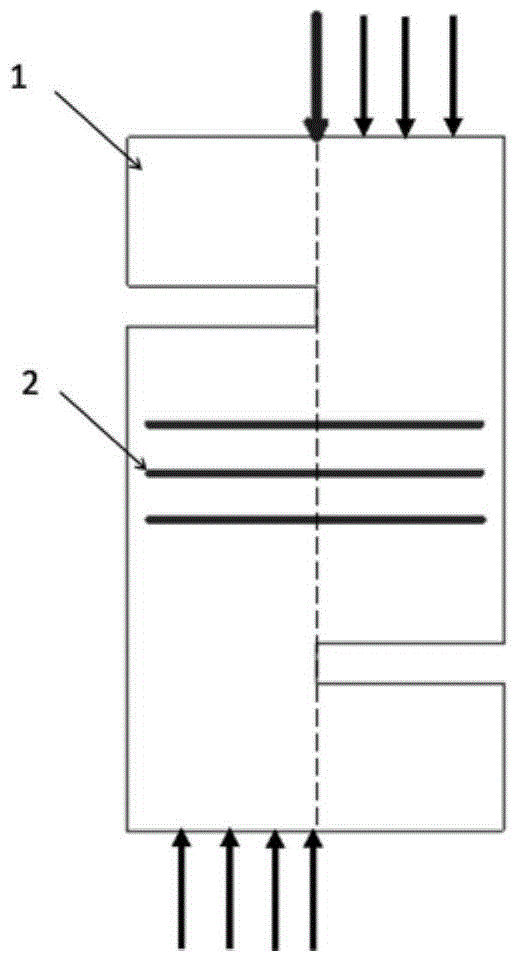

[0088] Such as Figure 9 , Figure 10 and Figure 11 As shown, the carbon fiber composite material is laid layer by layer on the outer surface of the pre-reinforced part of the reinforced concrete member. Under the action of load F, the carbon fiber composite stretches to both sides of the direct shear plane 4 (ie Figure 9 The direction X) is indicated by the double arrow shown. The length b of the carbon fiber composite varies with the specific parameters of the reinforced concrete member. In this embodiment, the length b is 400mm as an example for illustration. When pasting, the carbon fiber composite material is vertically pasted on the reinforcement part along the direction perpendicular to the potential direct shear surface 4, and the direct shear surface 4 is guaranteed to bisect the piece of carbon fiber composite material in the length direction, that is, the length of the reinforcement part is direct shear Surfaces 4 extend 200mm in the longitudinal direction, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com