Slurry-water balanced horseshoe-shaped shield machine

A mud-water balance and horseshoe-shaped technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of large impact on the formation disturbance and the environment, limit the scope of application of horseshoe-shaped tunnels, and fail to meet the requirements of environmental protection, etc., so as to improve the adaptability of the formation performance, expand the scope of application, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

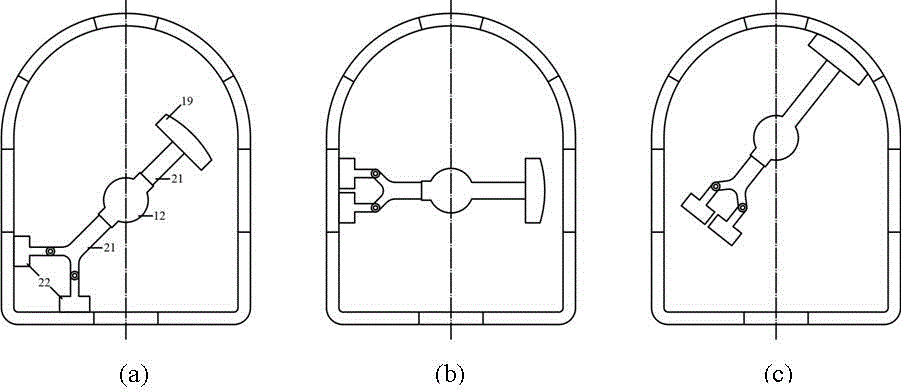

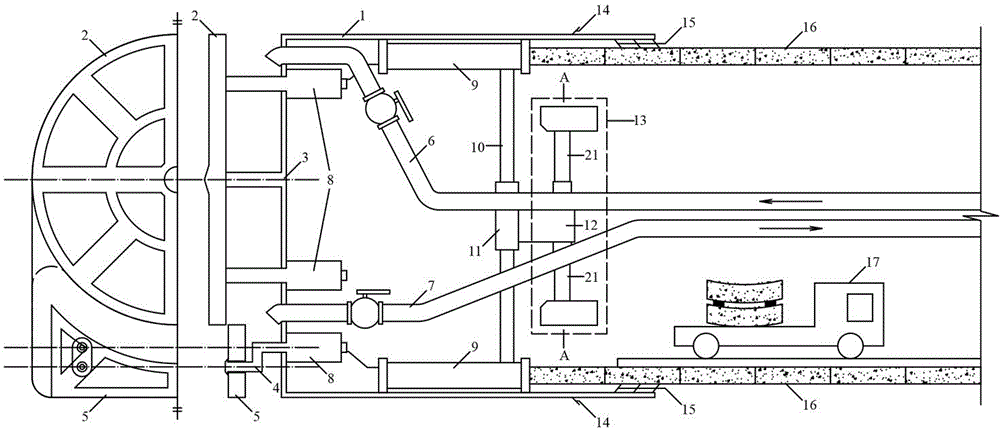

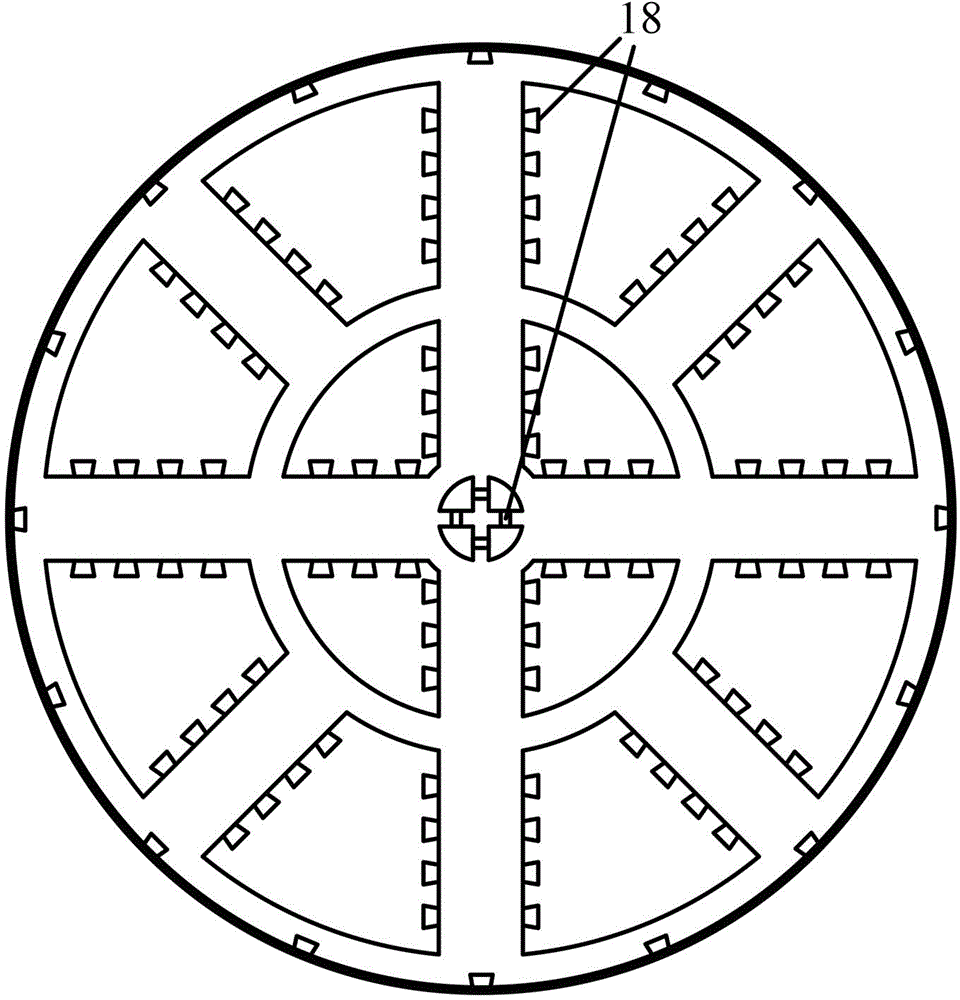

[0031] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, the horseshoe-shaped shield machine of the present invention includes: a shield casing 1, a cutterhead group at the front end of the shield casing 1 (composed of a circular cutterhead 2 and a special-shaped cutterhead 5), a double-head segment assembly machine 13 and other auxiliary devices. A scraper 18 is arranged on the circular cutter head 2 and the special-shaped cutter head 5 . The cutter head 2 is connected to the shield shell 1 through the shaft 3, and is connected to the power system by the main bearing 8; the cutter head 5 is connected to the shield shell 1 through the crankshaft 4, and is connected to the power system by the main bearing 8.

[0032] Such as figure 1 As shown, behind the cutter head group are the pulp inlet pipe 6 and the pulp outlet pipe 7. The soil cut by the shield machine is transported to the ground through the slurry outlet pipe 7, and new mud is replenished through the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com