A suction-energy-pressure tunnel support system and method suitable for weak and broken surrounding rock

A technology for crushing surrounding rocks and tunnels, which is applied in the field of tunnel support structure systems, can solve problems such as support system instability and damage, large deformation of surrounding rocks, etc., and achieve the effect of inhibiting the deterioration of plastic slip and alleviating instantaneous damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

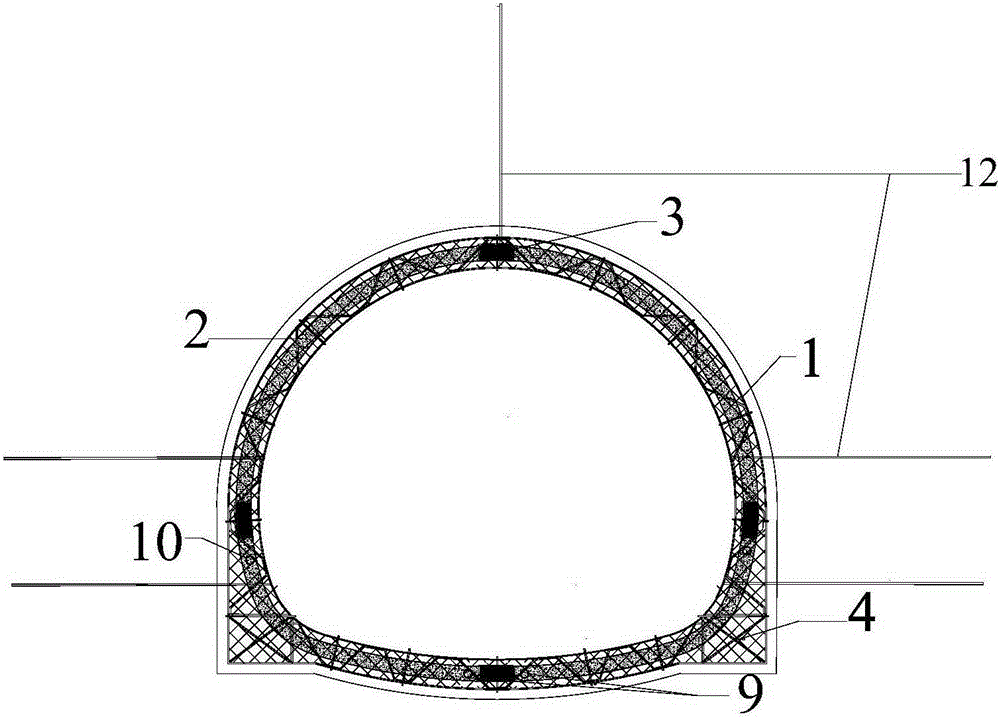

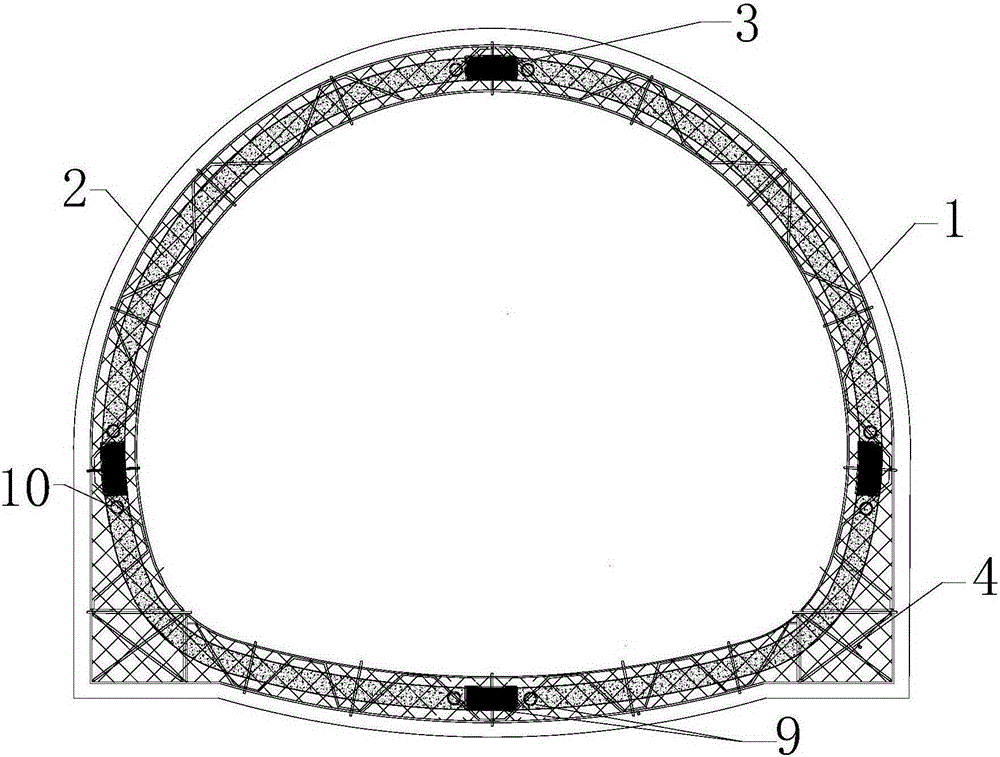

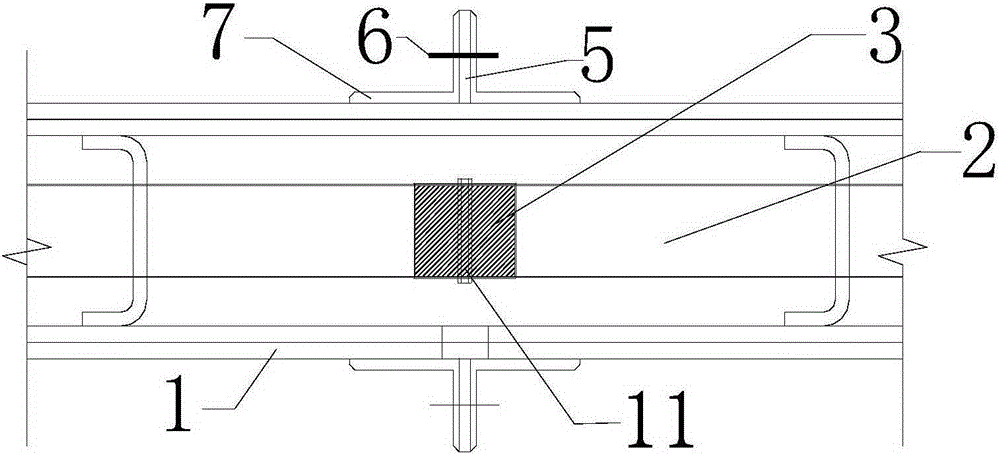

[0037] The device of the present invention mainly includes a grid steel frame 1, a concrete steel pipe 2, a casing 3, a longitudinal connecting beam 4, a rubber pad a5, a high-strength bolt 6, a grid connecting plate 7, an energy-absorbing pressure ring 8, a grouting hole 9, Exhaust port 10, rubber pad b11, prestressed anchor rod (cable) 12 and joists; the grid steel frame 1 is in the same shape as the tunnel section, and the structure is a closed structure, and the grid steel frame 1 is installed with concrete The steel pipe 2, the concrete steel pipe 2 and the grid steel frame 1 are connected through a sealed energy-absorbing pressure ring 8, and the combined bracket composed of the grid steel frame 1, concrete steel pipe 2 and the energy-absorbing pressure ring 8 is The tunnel is set at equal intervals, and the adjacent combined supports are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com