A multi-cylinder opposed piston type oil-free compression device

A technology of opposing pistons and compression devices, which is applied to piston pumps, multi-stage pumps, variable displacement pump components, etc., and can solve problems such as lubricating oil protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

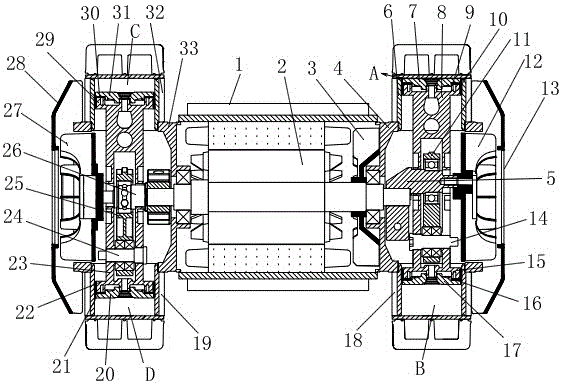

[0031] The multi-cylinder opposed piston type oil-free compression device includes a drive motor, a cylinder and an air guide cover. The output shaft of the drive motor is connected to a set of coaxially opposed piston assemblies that freely reciprocate in the cylinder. The piston assemblies are connected to the On the crankshaft connected to the output shaft of the drive motor, a crankcase is arranged between the crankshaft and the drive motor, and the piston assembly moves up and down regularly under the drive of the crankshaft.

[0032] Output shafts can be arranged on both sides of the drive motor, and the two output shafts of the drive motor are connected to a group of coaxially opposed piston assemblies that freely reciprocate in the cylinder. At this time, the crankshafts on both sides of the drive motor need They are staggered 90 degrees from each other, and the angles are staggered within one rotation cycle to achieve uniform compression.

[0033] The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com