Friction pair temperature test method

A test method and technology of friction pairs, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of high measurement accuracy, fast measurement speed, and unavailability, and achieve the effects of high precision, reasonable step design, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

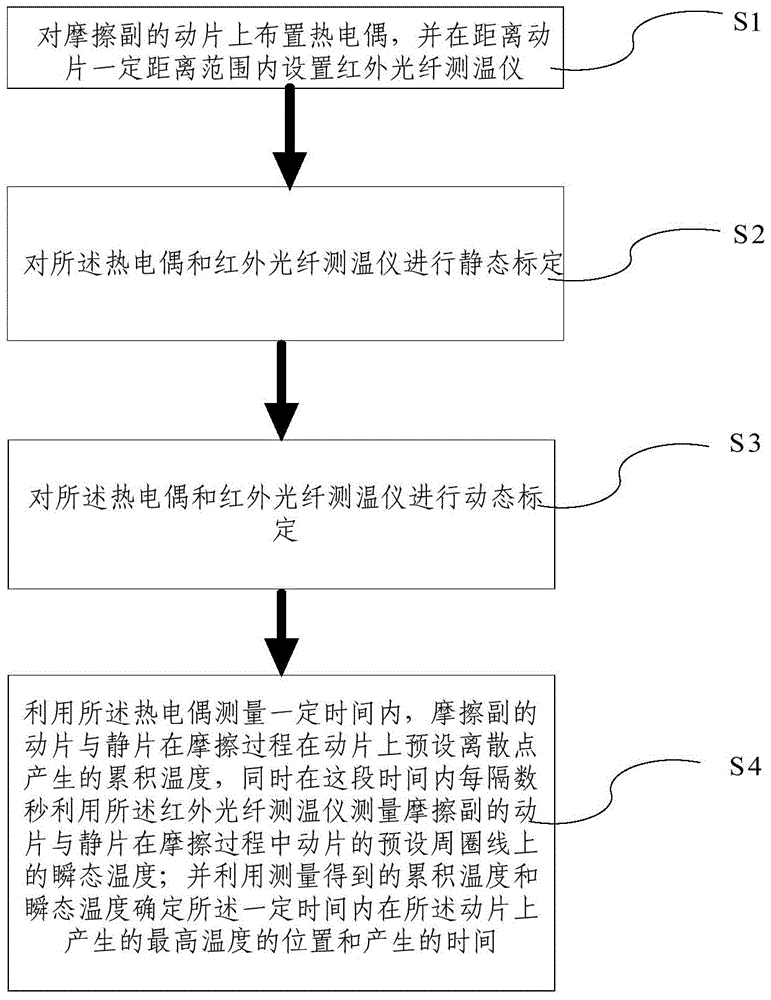

[0027] like figure 1 As shown, the present invention provides a friction pair temperature testing method, comprising the following steps:

[0028] S1. Arrange thermocouples on the moving plate of the friction pair, and install an infrared optical fiber thermometer within a certain distance from the moving plate;

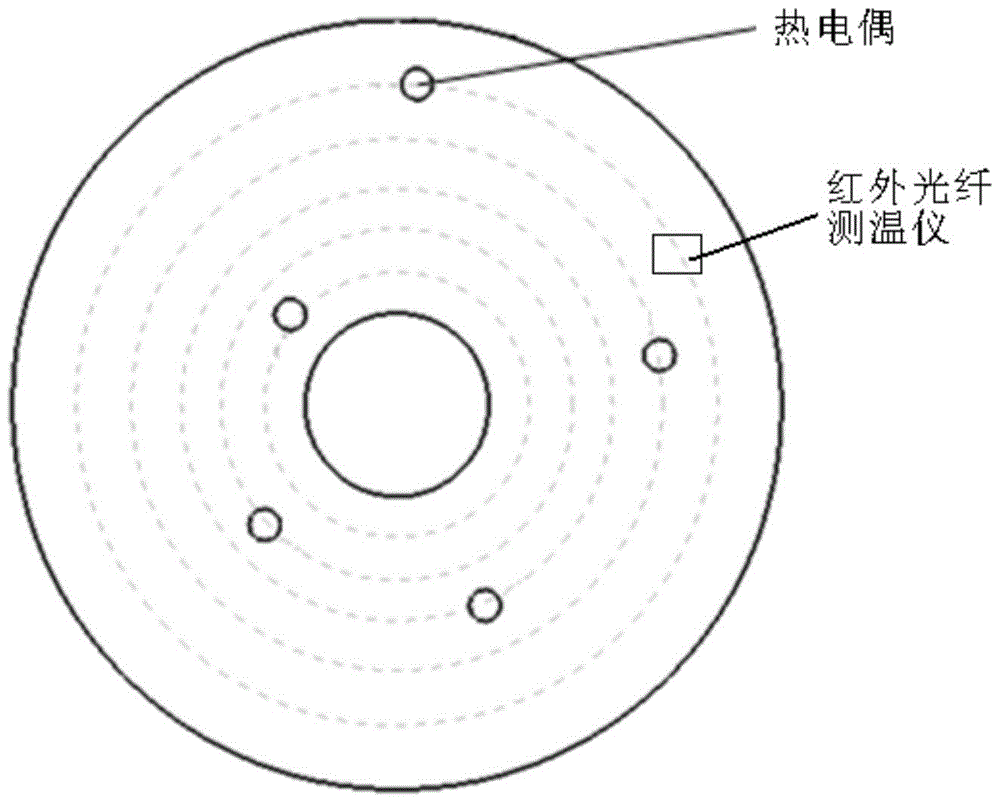

[0029] like figure 2 As shown, considering the size of thermocouples and strain gauges, and without affecting the friction effect, the way to arrange thermocouples is: open 5 slots on the moving plate, and each thermocouple is buried in 1 slot, so that To prevent the thermocouple from being damaged by friction, the 5 grooves are located at different positions with 5 different radii on the moving plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com