Wireless measuring device and method for measuring dynamic parameters of non-spherical particles in three-dimensional dense gas-solid system

A technology of non-spherical particles and dynamic parameters, which is applied in the field of multiphase flow measurement, and can solve problems such as inability to realize three-dimensional full-field measurement and disturbing flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

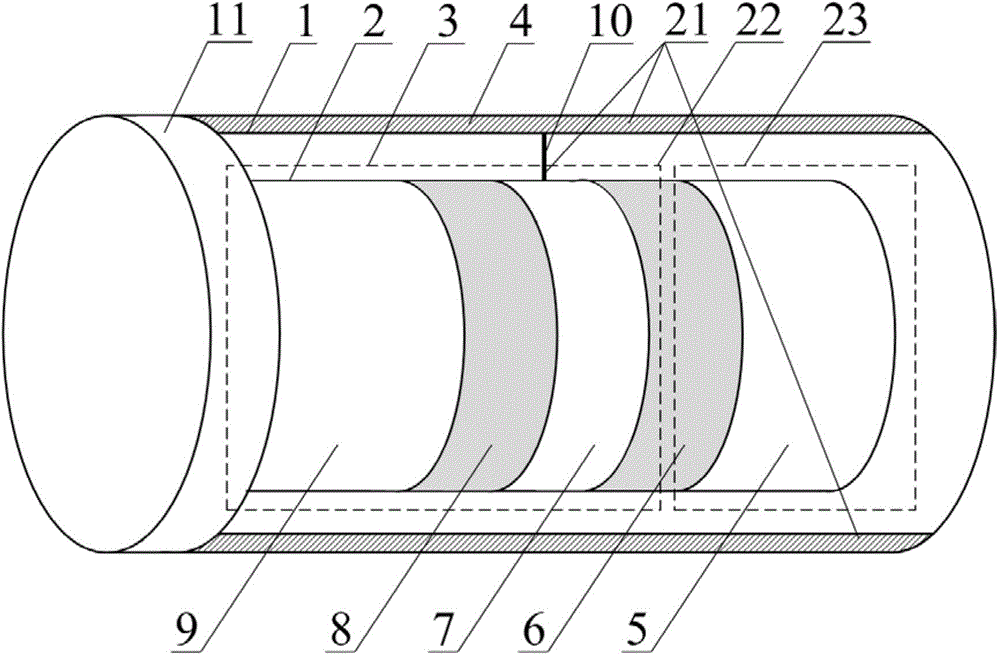

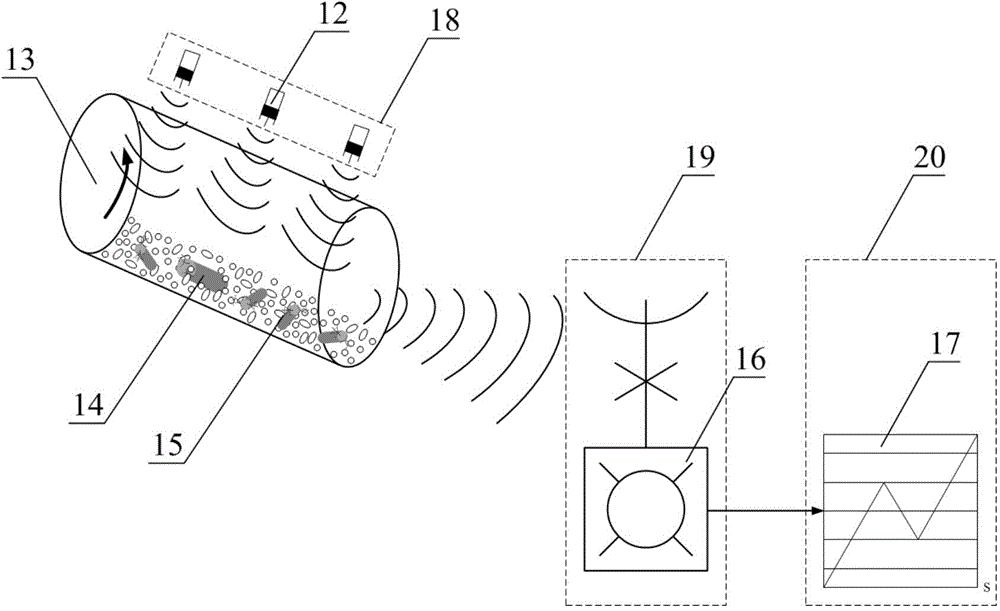

[0035] In this implementation, an experimental device is designed for the pyrolysis process of solid waste in a rotary kiln, which is used to measure the position change and impact force of solid waste under different operating parameters. The specific implementation steps are as follows:

[0036] (1) Prepare the experimental device and experimental materials. Take the rotary kiln (three-dimensional dense gas-solid system) as the experimental device, with a diameter of 500mm and a length of 1500mm. Experimental materials include spherical heat carriers and non-spherical materials. Quartz sand is used as heat carrier, and various solid wastes of different shapes are used as materials. A regular cylindrical material is selected from the non-spherical granular material to be detected, and the average diameter of the cylindrical material is 16 mm, and the average height is 48 mm.

[0037] (2) Make tracer particles. The shell and the core channel are respectively made of glass, ...

Embodiment 2

[0042] In this implementation, the experimental device is designed for the biomass fluidized bed combustion boiler, which is used to measure the collision force and corresponding position of the biomass particles during the fluidization process. The specific implementation steps are as follows:

[0043] (1) Prepare the experimental device and experimental materials. Take the fluidized bed (three-dimensional dense gas-solid system) as the experimental device, the cross-sectional area of the bed is 400mm×400mm, and the height is 2000mm. Experimental materials include spherical fluidized media and non-spherical materials. Quartz sand is used as the fluidized medium, and biomass straw particles of various shapes are used as materials. A regular cylindrical material is selected from the non-spherical granular material to be detected, and the average diameter of the cylindrical material is 15 mm, and the average height is 42 mm.

[0044] (2) Make tracer particles. The shell and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com