In-store measuring device for porosity of grains

A measuring device and porosity technology, which is applied in the field of grain porosity measuring device, achieves the effects of simple structure, low cost and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

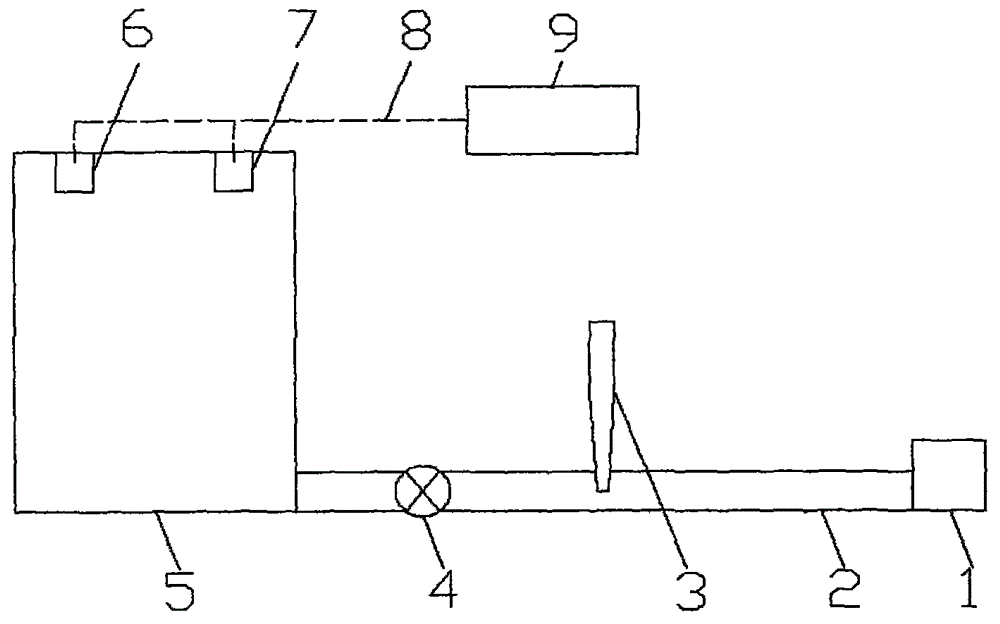

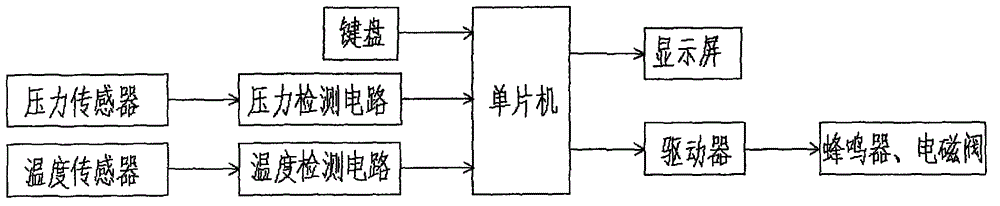

[0016] Fill the granary (5) with grain, measure the grain volume V T and pipe volume V 2 . Seal the granary (5), connect the pipeline, install the solenoid valve (4), pressure sensor (6), temperature sensor (7), insert the hot wire anemometer (3) into the pipeline vertically and open it. After confirming that the system connection is reliable, the detection circuit (9) is turned on and initialized, and the V T , V 2 , Grain variety and corresponding porosity reference range input single-chip microcomputer by keyboard, energize to electromagnetic valve (4), make it be in opening state. Turn on the blower fan (1) subsequently to blow air to the granary (5), and the pressure in the silo is changed from the atmospheric pressure P 0 up to peak P 1 , eventually tends to be stable, during which the single-chip microcomputer records the P measured by the sensor 0 ,P 1 , T 0 , T 1 value and pressure by P 0 up to P 1 elapsed time t 1 . The average flow q measured by the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com