Method for calculating wear shape of slide plate corresponding to rigid catenary design model

A rigid contact, design model technology, applied in the field of rail transit, can solve the problems of high installation and maintenance costs, high costs, and inability to realize locomotive detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

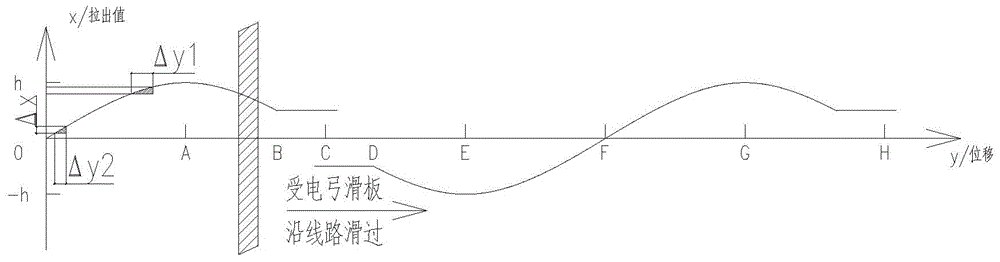

[0028] The layout model of overhead rigid catenary busbars and contact lines is regarded as a periodic function of pull-out value versus displacement mileage. Taking the commonly used "sine wave" model in China as an example, the trend of the overhead rigid catenary busbar and contact line in an anchor section is as follows: figure 1 , to study the function characteristics in a periodic OF interval, which can be expressed as

[0029] x = f ( y ) = a · sin ωy , y ∈ [ O , B ] k 1 y ...

Embodiment 2

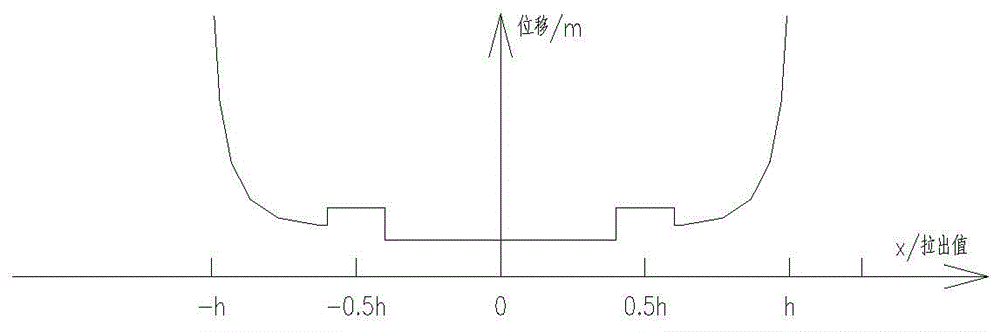

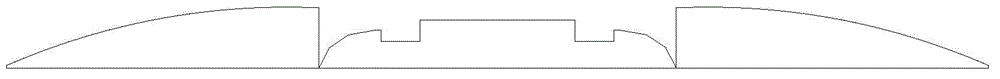

[0043] The layout model of overhead rigid catenary busbars and contact lines is regarded as a periodic function of pull-out value versus displacement mileage. Taking the "broken line" model obtained after the above analysis and solution as an example, the trend of the overhead rigid catenary busbar and contact line in an anchor section is as follows: Figure 5 , to study the function characteristics in a periodic OF interval, use the inverse function derivative method to solve such as Figure 5 The accumulated velocity waveform of the pull-out value corresponding to the arranged rigid catenary, such as Figure 6 ,right Figure 6 Mirroring and considering the waveform discrete, etc. to get the wear situation of the slide, such as Figure 7 . The corresponding skateboard wear is relatively smoother and more uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com