Switch-on and switch-off mechanism of automatic transfer switching equipment

An automatic transfer switch, opening and closing technology, applied in the field of electromechanical manufacturing, can solve the problems of reduced use efficiency, shortened service life of static contact components, increased costs, etc., and achieves simple structure, strong opening and breaking capacity, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

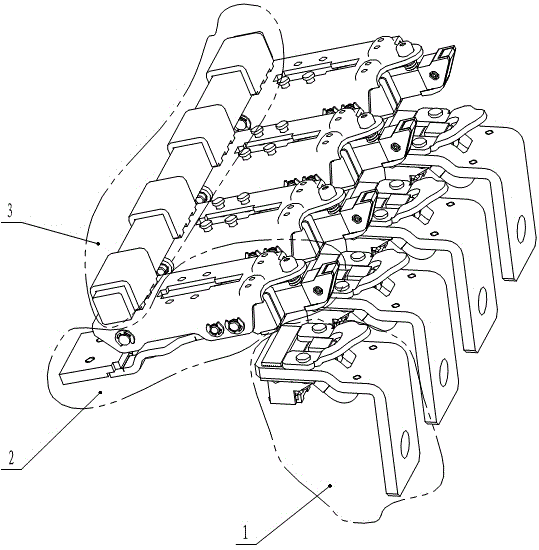

[0018] Such as figure 1 As shown, the opening and closing mechanism of the automatic transfer switching device of the present invention is composed of a static contact assembly 1 , a moving contact assembly 2 , and a square shaft assembly 3 . The opening and closing mechanism drives the moving contact assembly 2 to rotate through the rotation of the square shaft assembly 3 to complete the opening and closing of the static contact assembly 1 . figure 1 It is a 3D structural diagram showing the components of the opening and closing mechanism of the automatic transfer switch.

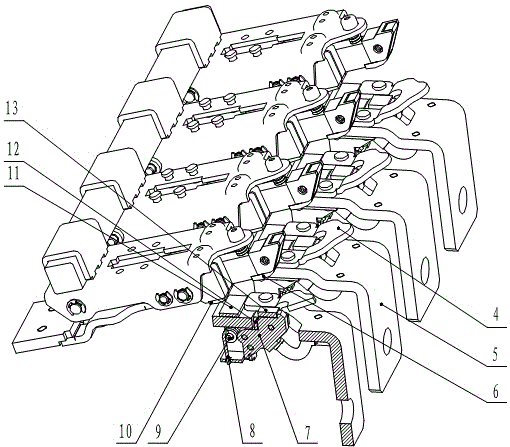

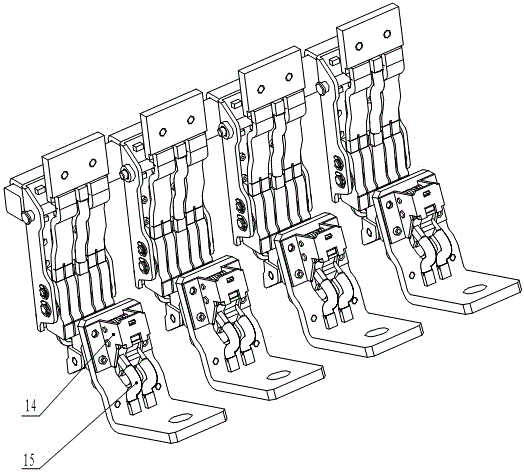

[0019] figure 2 It is the 3D structural diagram after sectioning of the partial static contact assembly; image 3 It is the 3D structural diagram of the bottom of the static contact assembly. Static contact assembly 1 is mainly composed of arc striker 4, AB power supply wiring board 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com