Thermal management system and method for power battery pack

A power battery pack and thermal management system technology, applied in the thermal management system field of power battery packs, can solve problems such as difficult maintenance, low heating efficiency, and high cost, and achieve the effects of simple structure, convenient installation, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

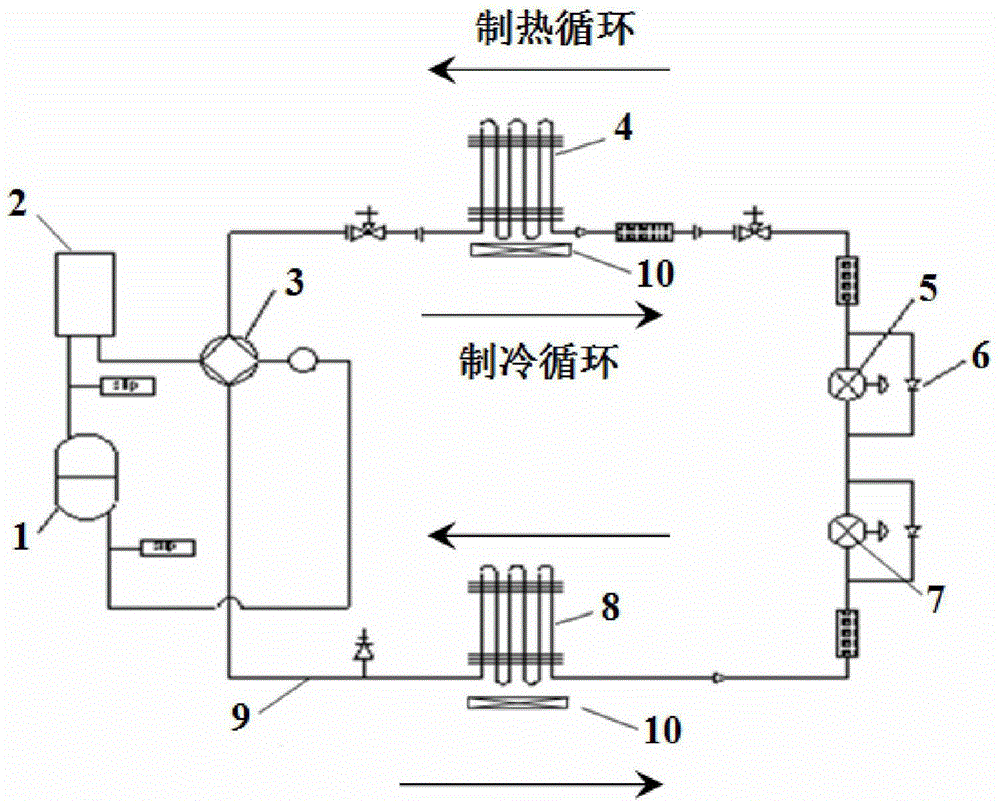

[0037] Heat pump technology is a new energy technology that obtains low-grade heat energy from natural air, water or soil, and provides high-grade heat energy through electricity. It has attracted much attention worldwide in recent years. coefficient), that is, the ratio of the heat transferred from a low-temperature object to a high-temperature object to the required power. The invention enables the power battery pack to work at a suitable ambient temperature by applying the heat pump technology to the thermal management of the power battery pack. The structure of the thermal management system of the power battery pack is as follows: figure 1 As shown, including heat pump device and thermal management unit, where:

[0038] The heat pump device includes a compressor 1, a closed loop formed by two of the four-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com