High-density labor-saving shaping cultivation method for grape vine

A cultivation method and high-density technology, applied in the field of high-density and labor-saving tree shaping cultivation of grapes, can solve the problems of complex tree arrangement, affecting fruit quality, and canopy closure on the canopy surface, so as to ensure ventilation and light, good ventilation and safety. Lighting, the effect of promoting reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] include:

[0025] 1. To level the land and raise ridges;

[0026] 2. Determine a reasonable planting density, preferably with a row spacing of 2.8m and a plant spacing of 1m;

[0027] 3. Variety selection: the present invention can select suitable heavy and short-cut grape varieties such as Golden Finger, Sunshine Rose, and Summer Black.

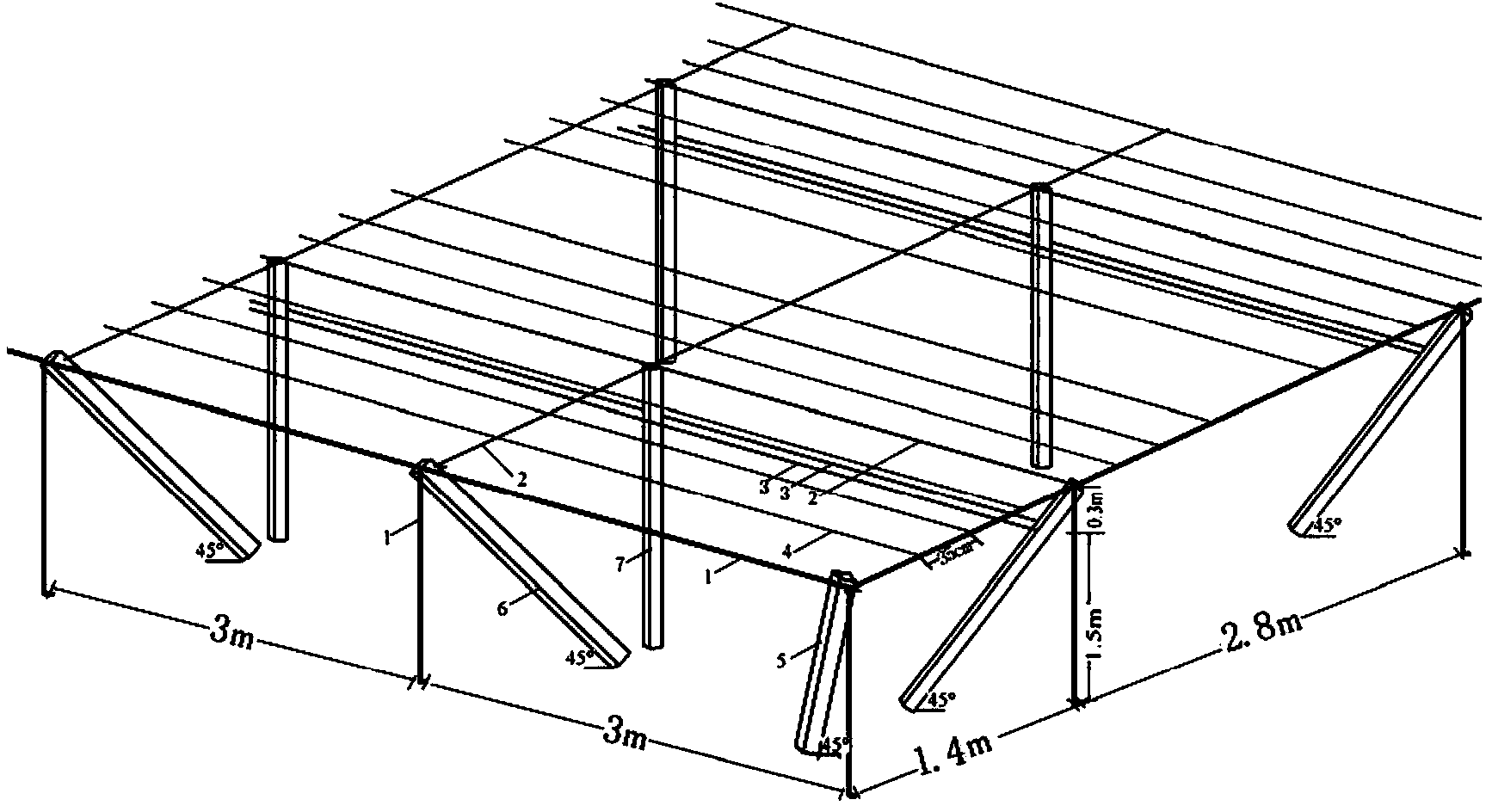

[0028] 4. Build a frame suitable for high-density and labor-saving cultivation of grapes. The height of the scaffold is 1.8-1.9m. It is built with cement columns. The horizontal spacing of the side columns is 2.8m, and the vertical spacing is 3m. Tilt outward, the top of the column is fixed with iron wire, No. 8 galvanized iron wire is used for the surrounding and side column stay wires, No. 10 galvanized wire is used for the side column pair of stay wires, and each intersection point of the pair of stay wires in the middle of the scaffold is vertically supported by the top column. (Along the row direction) Three No. 14 galvanized i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com