Automatic feeding and blade coating integrated device of chocolate chips

An automatic feeding and chocolate technology, applied in the direction of transportation and packaging, conveyor objects, cocoa, etc., can solve the problem that the skill level of operators affects product quality and production speed, cannot meet the requirements of high quality and high speed, and has a large operating workload and other issues, to achieve the effect of improving production flexibility and production efficiency, simple structure, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

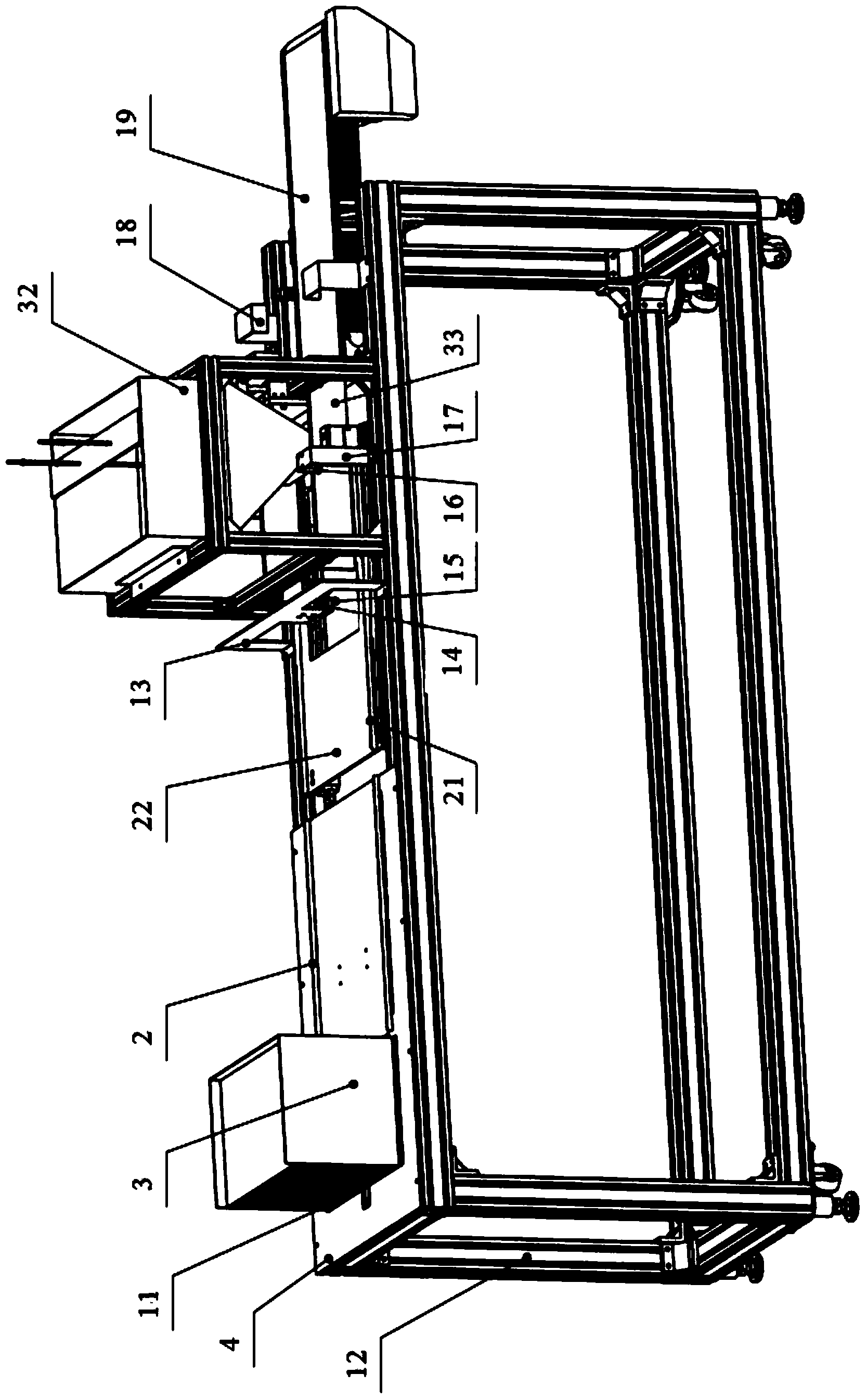

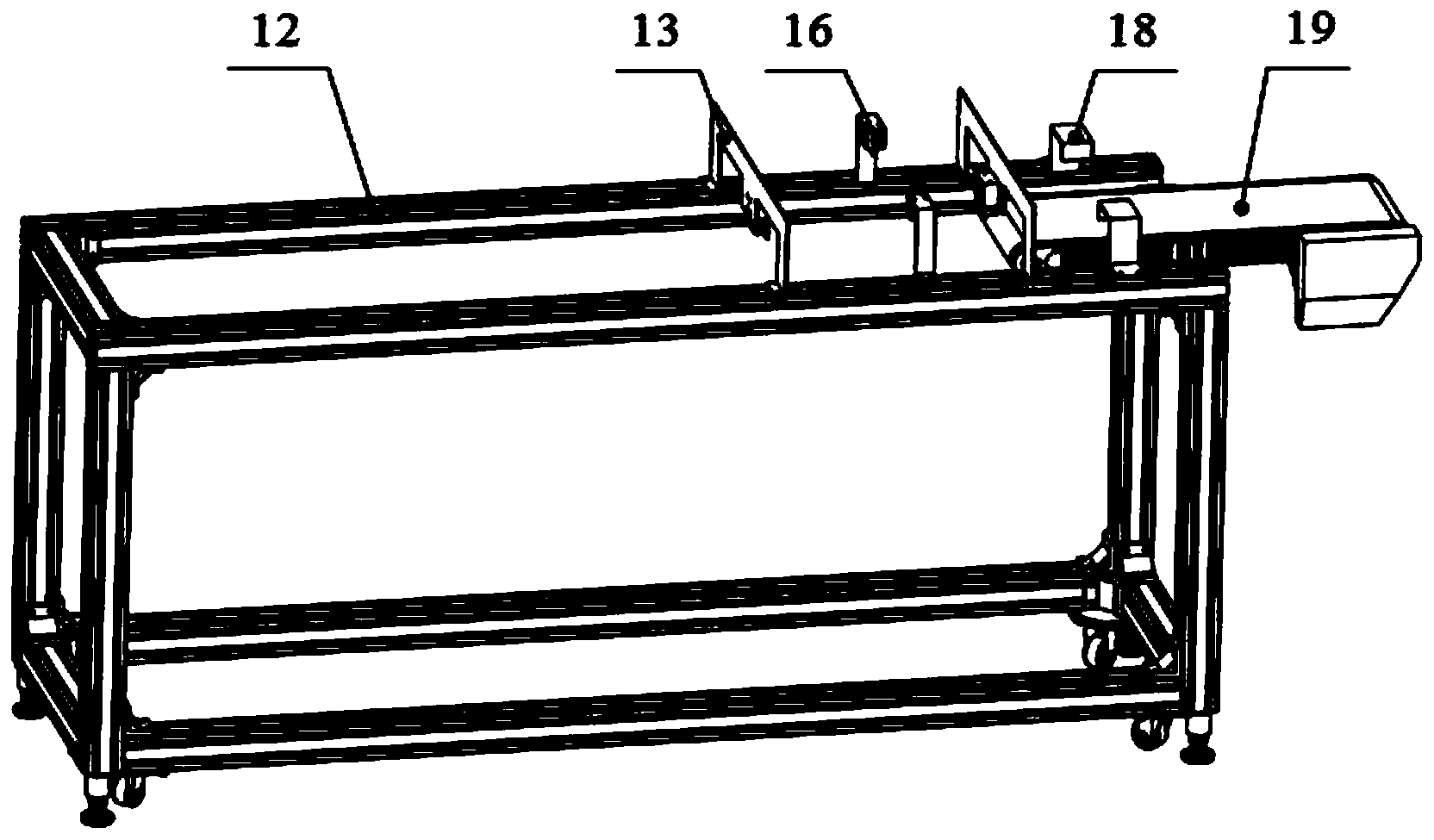

[0030] Please refer to the accompanying drawings, a kind of chip chocolate automatic feeding and scraping integrated device, including a frame 12 and a tray feeding mechanism, a workbench and a conveyor belt 19 arranged on the frame 12 in sequence, above the workbench there is A squeegee mechanism, the squeegee mechanism is installed on the frame 12 .

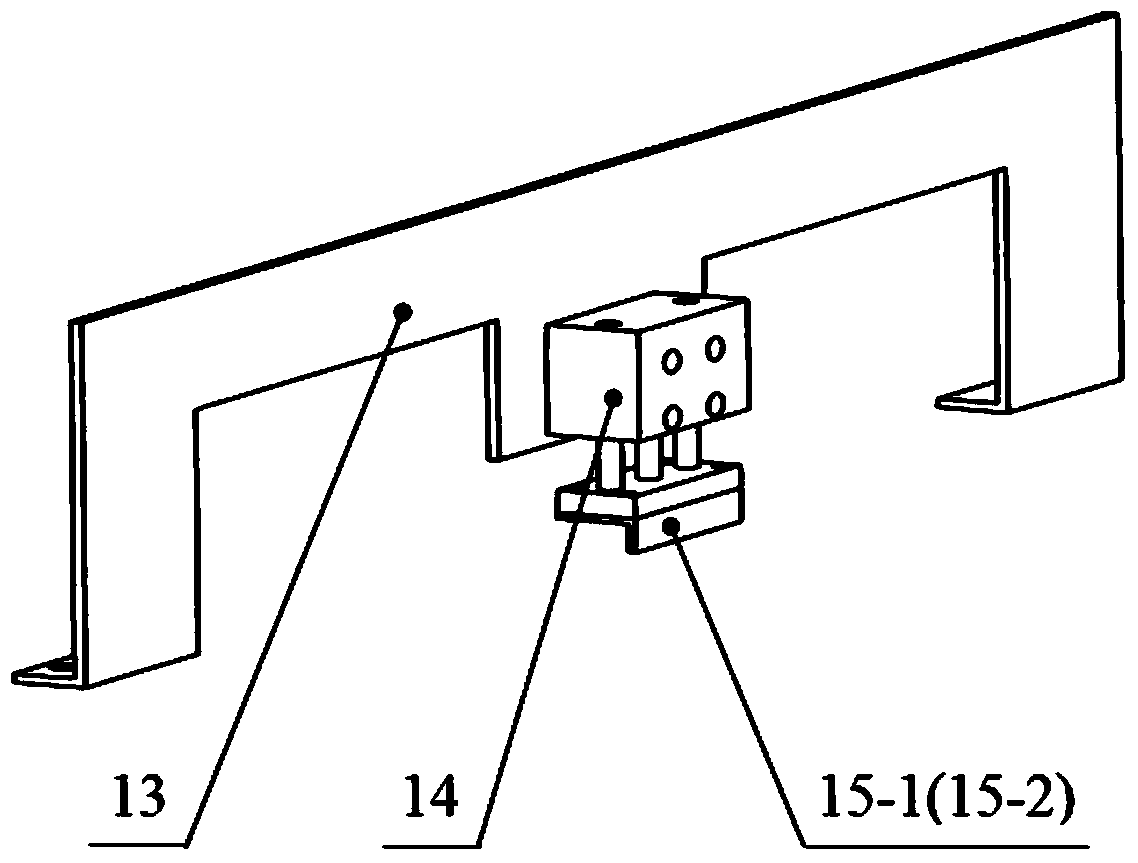

[0031] see figure 1 with Figure 5-1 to Figure 5-4 , the tray feeding mechanism includes a tray storage box 3, the tray storage box 3 is buckled on the bottom plate 4, the bottom plate 4 is fixed on the frame 12, and a tray transfer slot is provided on the bottom plate 4 And the tray guide side baffle I2, the tray guide side baffle I2 is located in front of the tray storage box 3, the tray 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com