Fire extinguishing protective system for passenger compartment of bus

A protection system and passenger cabin technology, applied in the field of fire protection systems, can solve the problems of difficult combustion, low combustion ratio, and fire extinguishers transporting fire extinguishers, so as to reduce casualties and property losses, reduce panic, and avoid high temperature injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

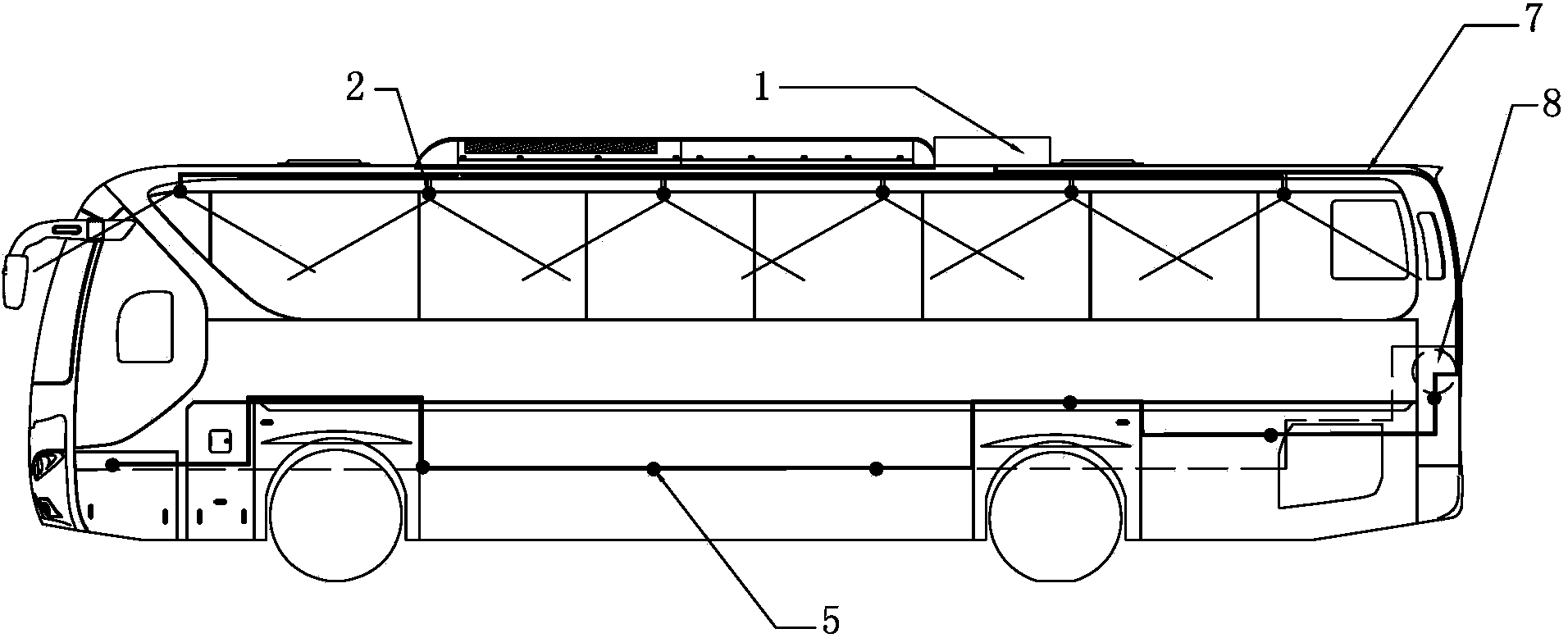

[0040] See Figure 1-Figure 5 As shown, a fire protection system for the passenger compartment of a passenger car of the present invention includes:

[0041] A water mist spraying device, which includes a water storage tank 1 installed on a passenger car and containing a water agent 1, a first conveying pipe 3 and a first water mist nozzle 2, the first water mist nozzle 2 being arranged on the top of the inner side of the passenger car, The water storage tank 1 is connected to the water storage tank 1 through the first conveying pipe 3; the water storage tank 1 is connected with a power mechanism; here, there are multiple first water mist nozzles 2 arranged in a row and arranged at intervals along the long axis direction of the top surface of the passenger car. Above the aisle in the center of the top of the passenger car;

[0042] Fire extinguishing device, the fire extinguishing device includes a gas fire extinguishing mechanism, the gas fire extinguishing mechanism includes a fi...

Embodiment 2

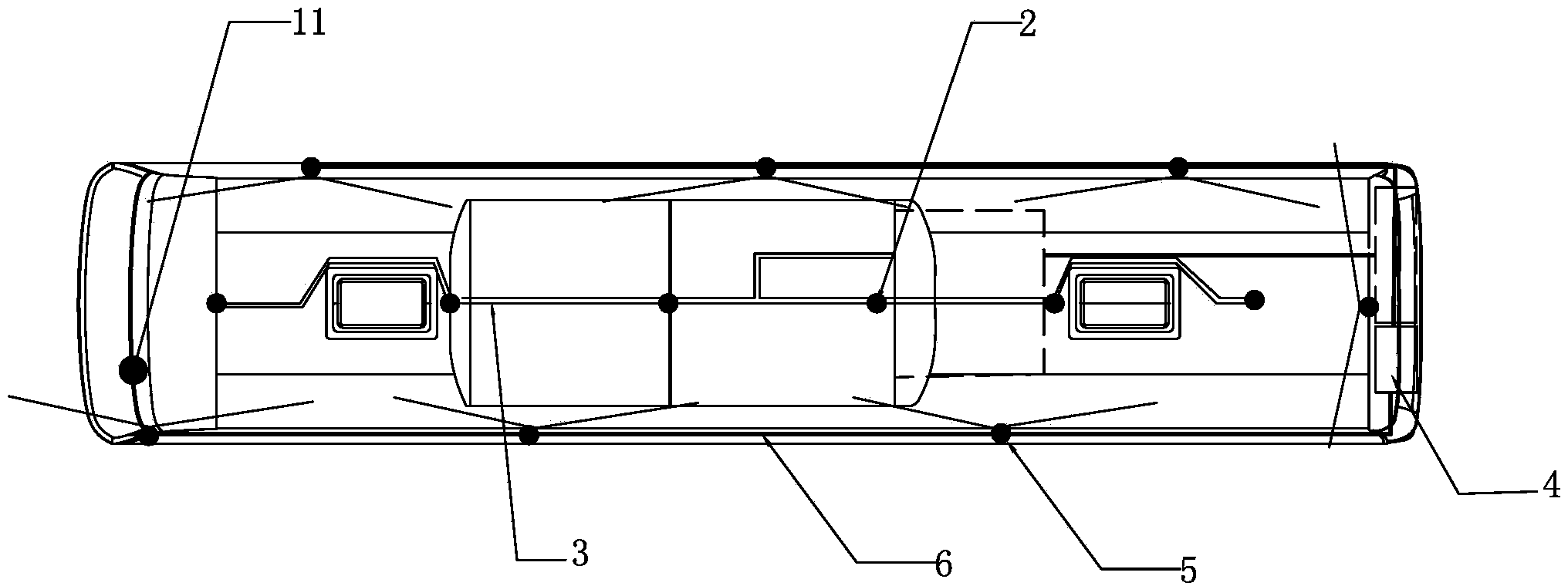

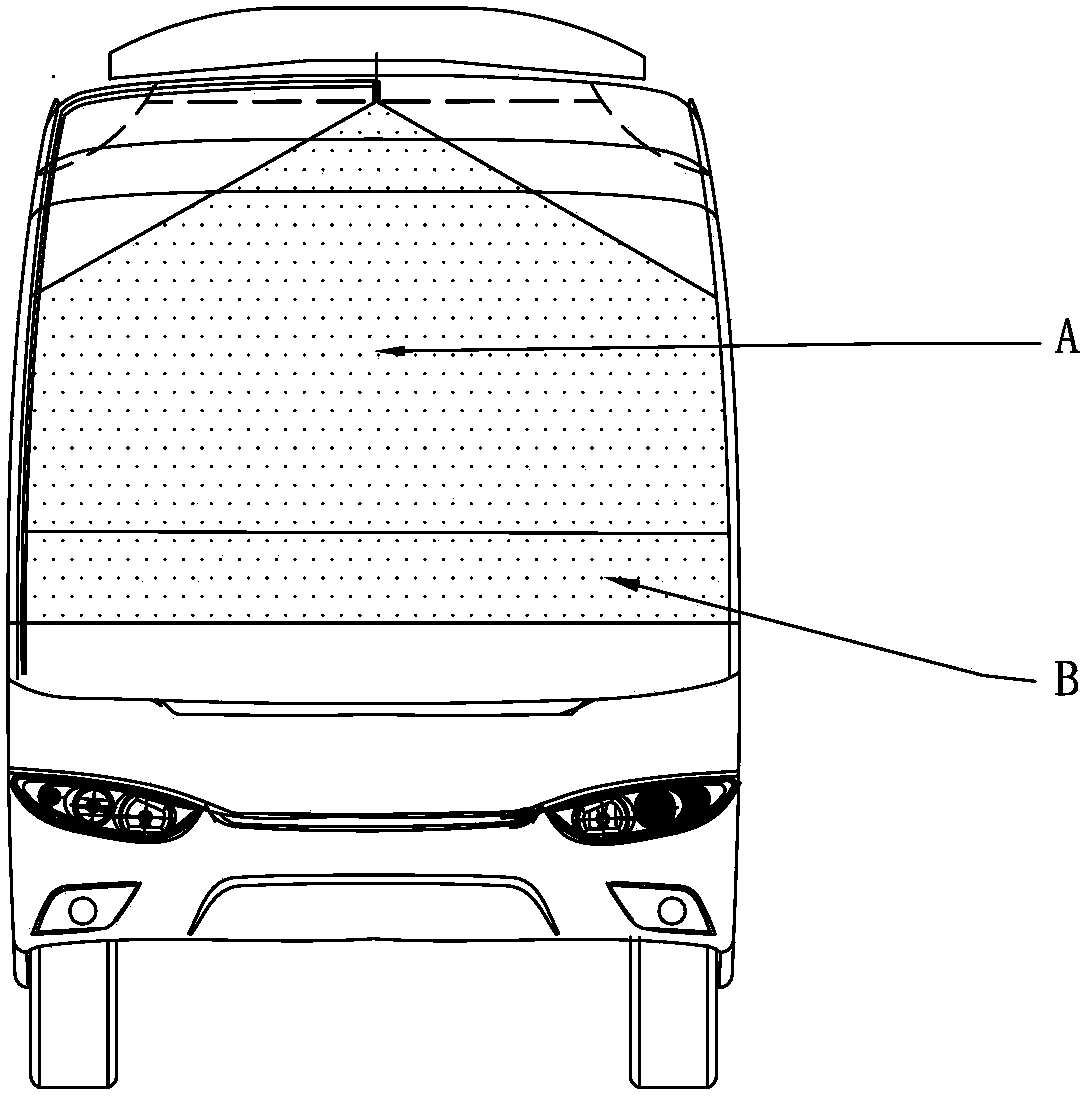

[0053] See Figure 6-Figure 8 As shown (the parts of the gas fire extinguishing mechanism and power mechanism in the figure are the same as above, omitted), the passenger car passenger compartment fire extinguishing protection system of the present invention is different from the first embodiment: the water mist spraying device The water storage tank 1 is installed on the front side of the bottom of the passenger car, and its multiple first water mist nozzles 2 are divided into two rows. The two rows of first water mist nozzles 2 are arranged side by side along the long axis of the passenger car and are respectively located in the two rows of the passenger car. The upper position of the chair; the two rows of first water mist spray nozzles 2 are connected by an annular first conveying pipe 3, and the first conveying pipe 3 extends downward to connect to the water storage tank 1. Such as Figure 8 As shown, the Figure 8 The middle part C indicates the spraying range of the first...

Embodiment 3

[0055] See Figure 9-11 As shown (the parts of the gas fire extinguishing mechanism and the power mechanism in the figure are the same as above, omitted), the difference from the first embodiment is that there are three rows of seats inside the passenger car, and the water storage tank 1 of the water mist spray device is installed On the rear side of the bottom of the passenger car, the plurality of first water mist nozzles 2 are divided into two rows, and the two rows of first water mist nozzles 2 are respectively arranged side by side along the long axis of the passenger car and are respectively located between two rows of adjacent seats of the passenger car Above the aisle; the two rows of first water mist nozzles 2 are connected by a ring-shaped first conveying pipe 3, and the first conveying pipe 3 extends downward to connect to the water storage tank 1. Such as Picture 11 As shown, the Picture 11 The middle part D represents the spraying range of the first water mist noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com