Random copolymerization polypropylene thermal forming special-use resin with wide molecular weight distribution and preparation method

A technology of wide molecular weight distribution and molecular weight distribution is applied in the field of producing random copolymer polypropylene resin with wide molecular weight distribution. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

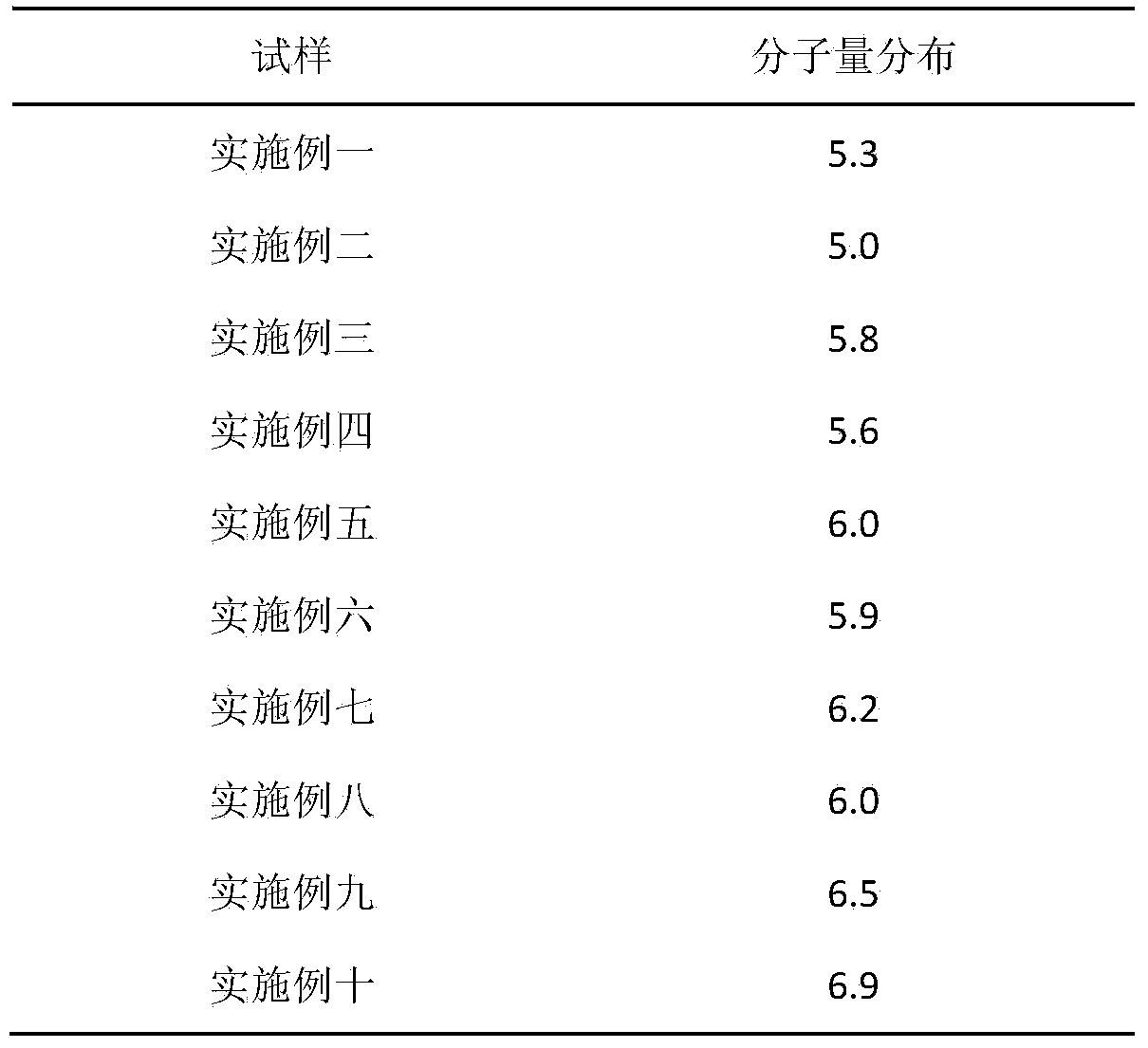

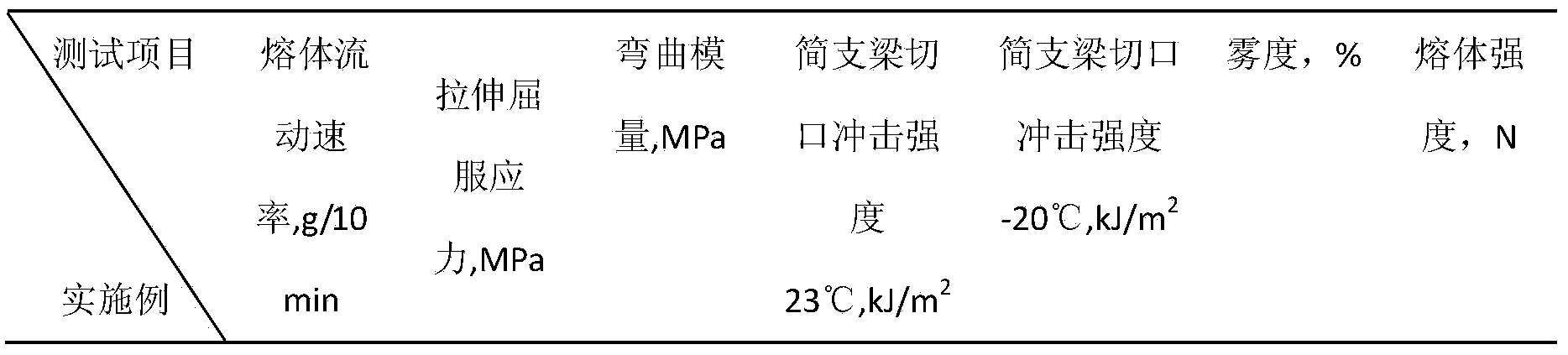

Examples

Embodiment 1

[0020] In the single-loop polypropylene unit of the Spheripol process of LBI Company, a new type of wide molecular weight distribution catalyst NDQ (activity of 21000g polypropylene / g catalyst) is used. The NDQ catalyst is provided by the Beijing Research Institute of Chemical Industry (the same below); the addition of liquid with a purity of 99.7% Propylene and ethylene with a purity of 99.9%, the addition of ethylene is 1.2%wt, to produce a random copolymerized polypropylene base resin with a wide molecular weight distribution (Mw / Mn=5.0-6.0), the melt index is 3-4g / 10min, and then passed A high-efficiency additive system is added to produce a special resin for random copolymerization polypropylene thermoforming. The high-efficiency additive system is expressed in parts by weight. The wide molecular weight distribution random copolymerized polypropylene resin raw material is 100 parts, and the auxiliary additives are 0.0244 parts of antioxidant 1010, 0.0489 parts of antioxida...

Embodiment 2

[0022]In the single-loop polypropylene device of LBI company Spheripol process, a wide molecular weight distribution catalyst NDQ is used, (the activity is 25000g polypropylene / g catalyst,) adding liquid propylene with a purity of 99.7% and ethylene with a purity of 99.9%, and the amount of ethylene added is 1.5 %wt, to produce random copolymer polypropylene resin with wide molecular weight distribution (Mw / Mn=5.0~6.0), the melt index is 3~4g / 10min, the high-efficiency additive system is expressed in parts by weight, and the wide molecular weight distribution is random The raw material of copolymerized polypropylene resin is 100 parts, and the auxiliary additives are 0.0269 parts of antioxidant 1010, 0.0538 parts of antioxidant 168, 0.0269 parts of calcium stearate, 0.1344 parts of GMS, and 0.0538 parts of organic carboxylate nucleating agent , added to a high-speed mixer and fully mixed, mixed at a low speed of 300r / min for 1.5 minutes and then mixed at a high speed of 1500r / m...

Embodiment 3

[0024] In the single-loop polypropylene unit of LBI company Spheripol process, a wide molecular weight distribution catalyst NDQ is used, (the activity is 28000g polypropylene / g catalyst,) adding liquid propylene with a purity of 99.7% and ethylene with a purity of 99.9%, and the amount of ethylene added is 1.8 %wt, to produce random copolymer polypropylene resin with wide molecular weight distribution (Mw / Mn=5.0~6.0), the melt index is 3~4g / 10min, the high-efficiency additive system is expressed in parts by weight, and the wide molecular weight distribution is random The raw material of copolymerized polypropylene resin is 100 parts, and the auxiliary additives are 0.0293 parts of antioxidant 1010, 0.0587 parts of antioxidant 168, 0.0293 parts of calcium stearate, 0.1467 parts of GMS, and 0.0293 parts of organic carboxylate nucleating agent , added to a high-speed mixer and fully mixed, mixed at a low speed of 300r / min for 1.5 minutes and then mixed at a high speed of 1000r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com