An automatic decoupling sling

A technology of automatic decoupling and lifting gear, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as difficulty in backfilling earthwork, large mechanical equipment, and inability to meet construction needs, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

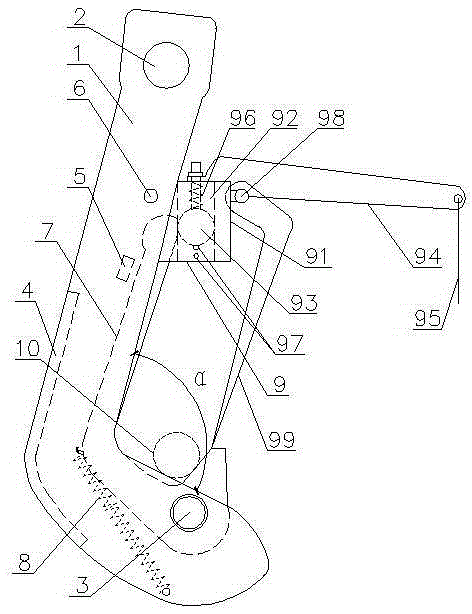

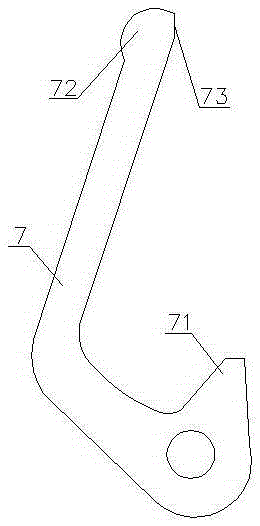

[0019] like figure 1 , figure 2 The shown automatic unhooking hanger includes two main hooks 1 whose lower parts are connected symmetrically by the auxiliary hook shaft 3, and a lifting hole 2 is provided on the upper end of the main hook 1, and the inner edge angle α of the main hook 1>90° , to meet the critical angle at which the weight is automatically slid. Hinged on the auxiliary hook shaft 3 is an auxiliary hook 7 positioned between the two main hooks 1, the upper end of the auxiliary hook 7 is provided with a contact 72, and the lower end is provided with a hook tip 71 protruding upwards from the inner edge of the main hook 1. One side of the head 72 is provided with a sliding section 73 tangent to the sliding part of the sliding pin 93 , and the sliding section 73 is located in the vertical plane. The outer edge of the auxiliary hook 7 is provided with a return extension spring 8, and the other end of the return extension spring 8 is fixed on the inner wall of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com