Slinging method

A sand bag and platform technology, which is applied in the field of scouring protection of base-type platforms, can solve problems such as platform emptying, and achieve the effects of meeting construction requirements, tight connection and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

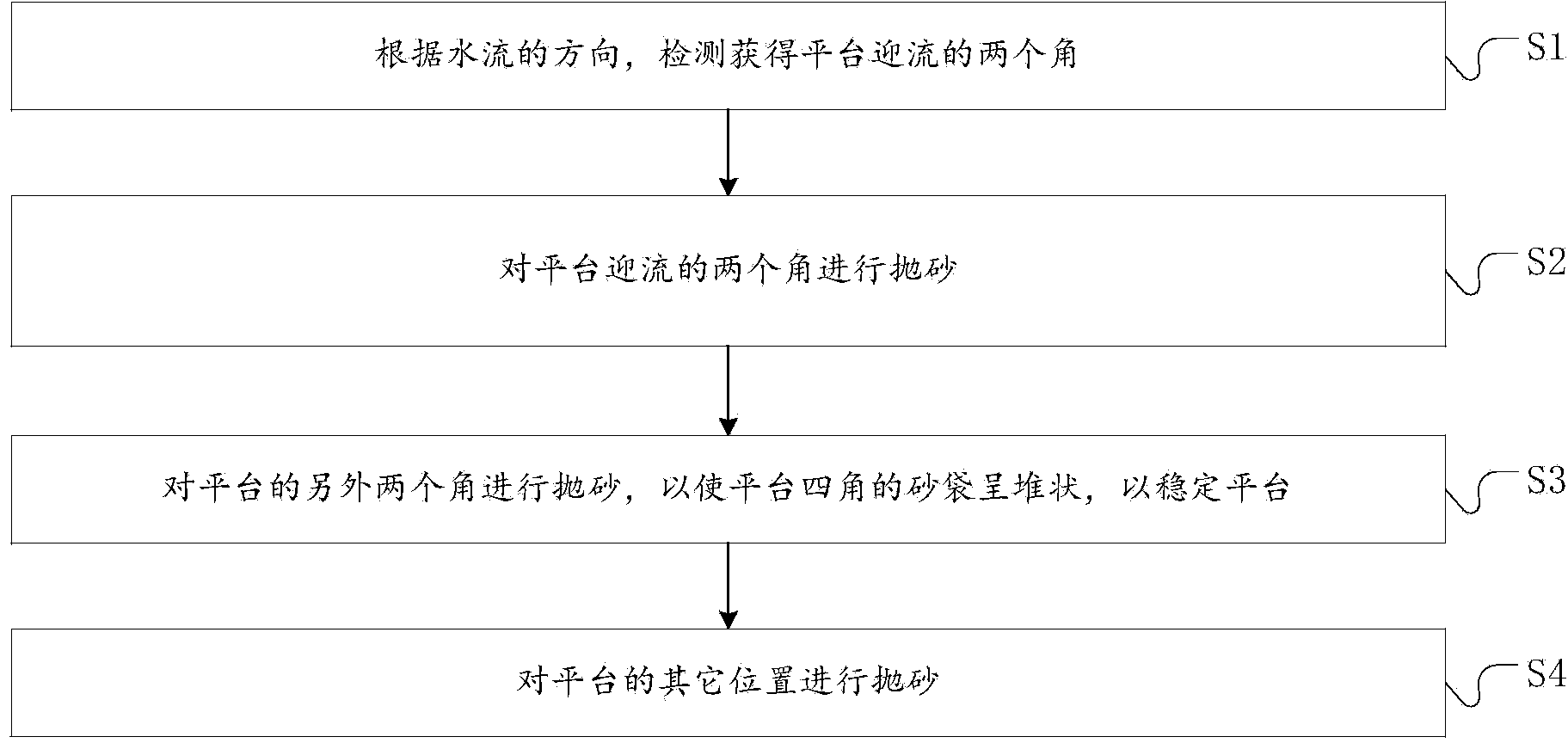

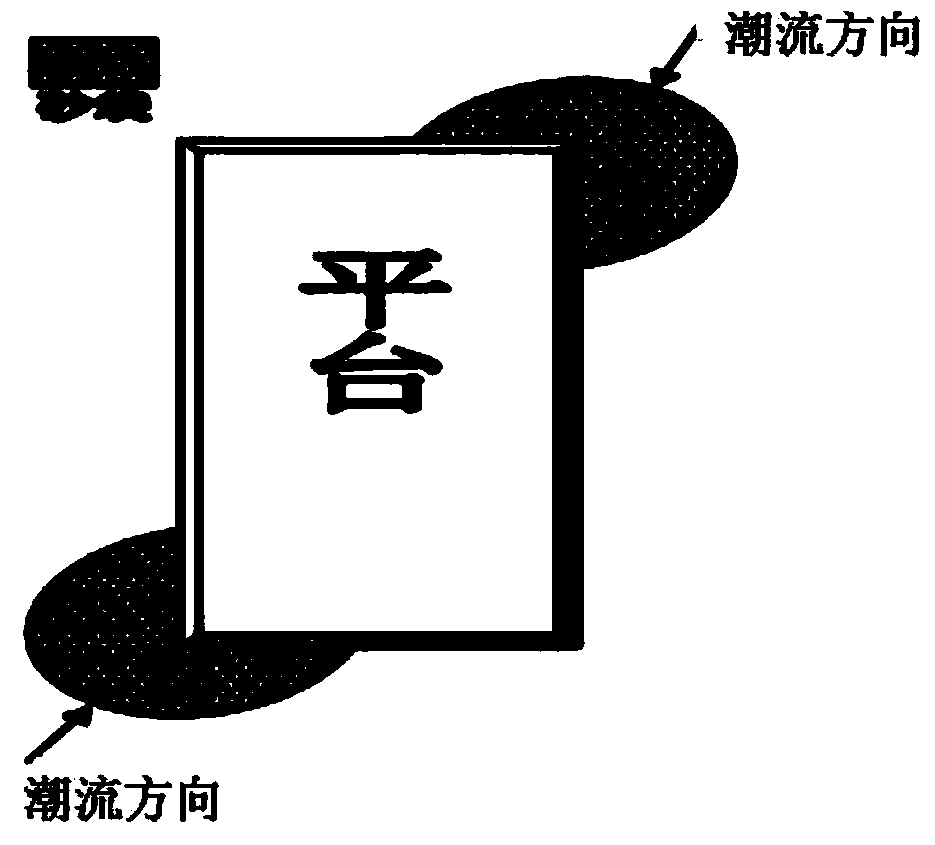

[0014] Embodiments of the present invention describe a sand blasting method for providing scour protection for a pedestal platform.

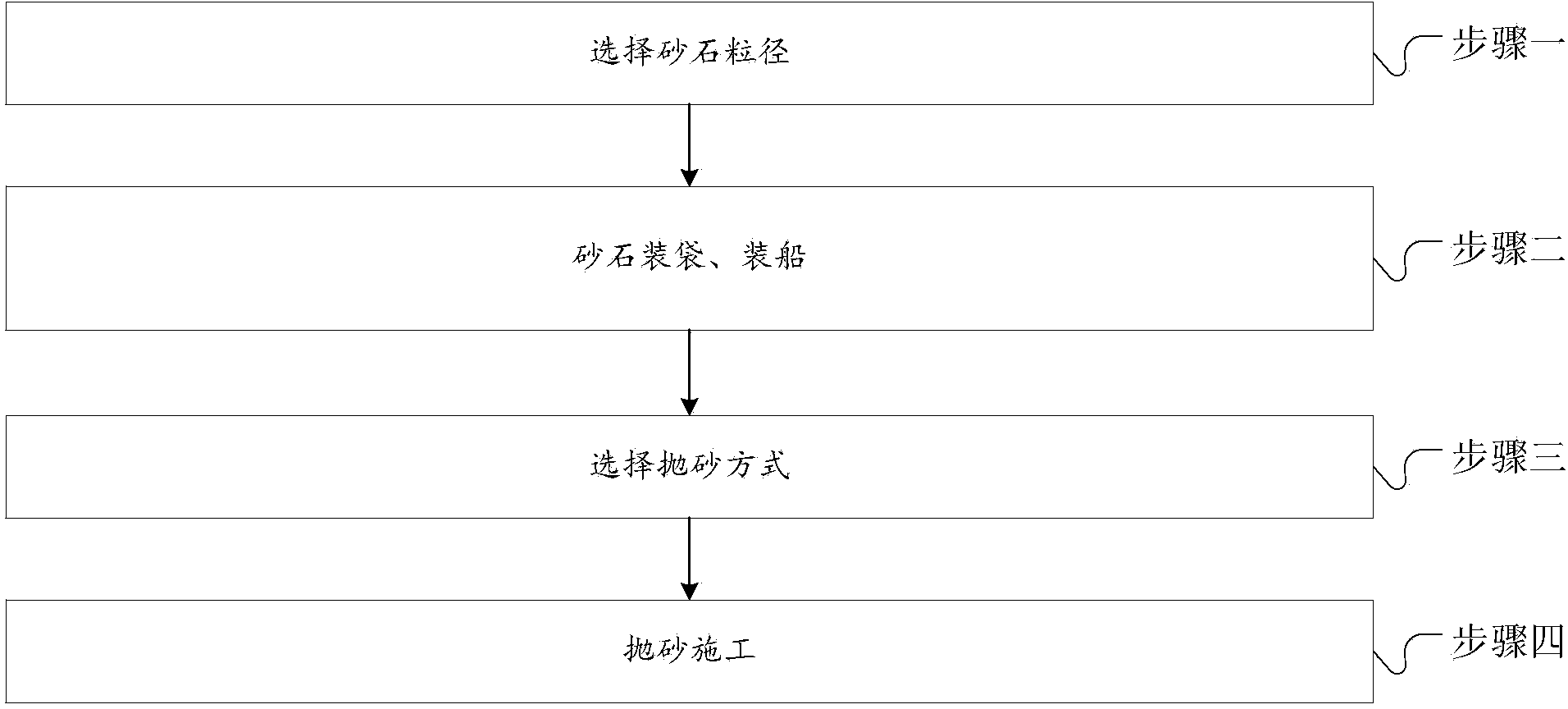

[0015] See below figure 1 , describing the whole process from sand selection to sand blasting.

[0016] Step 1: Select the particle size of the sand and gravel.

[0017] Detect the speed of water flow; determine the diameter of sand particles according to the speed of water flow.

[0018] Firstly, according to the actual measured water flow velocity at the well location, compared with the Urstron sand particle----flow velocity logarithmic curve, considering the sand blasting construction and the operation safety of the subsequent platform, the sand and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com