Gunship transparent part fastening structure with explosion preventing and buffering functions and fastening method

A technology for fastening structures and transparent parts, which is applied to the installation of aircraft accessories, aircraft parts, and window glass. It can solve problems such as gaps, maintenance work tests, and cracks in bolt holes, so as to avoid assembly stress and improve assembly. Interchangeability, the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with specific examples.

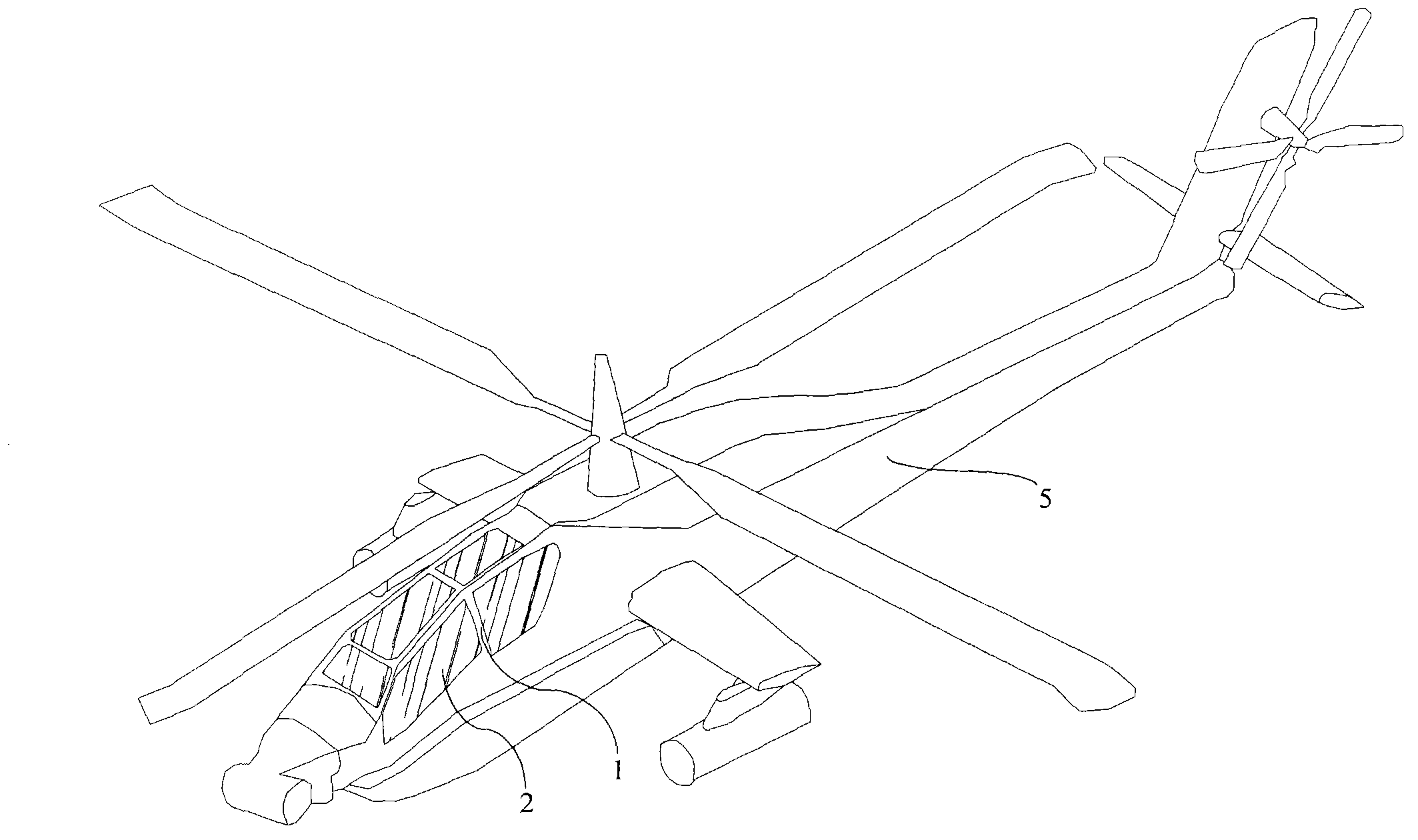

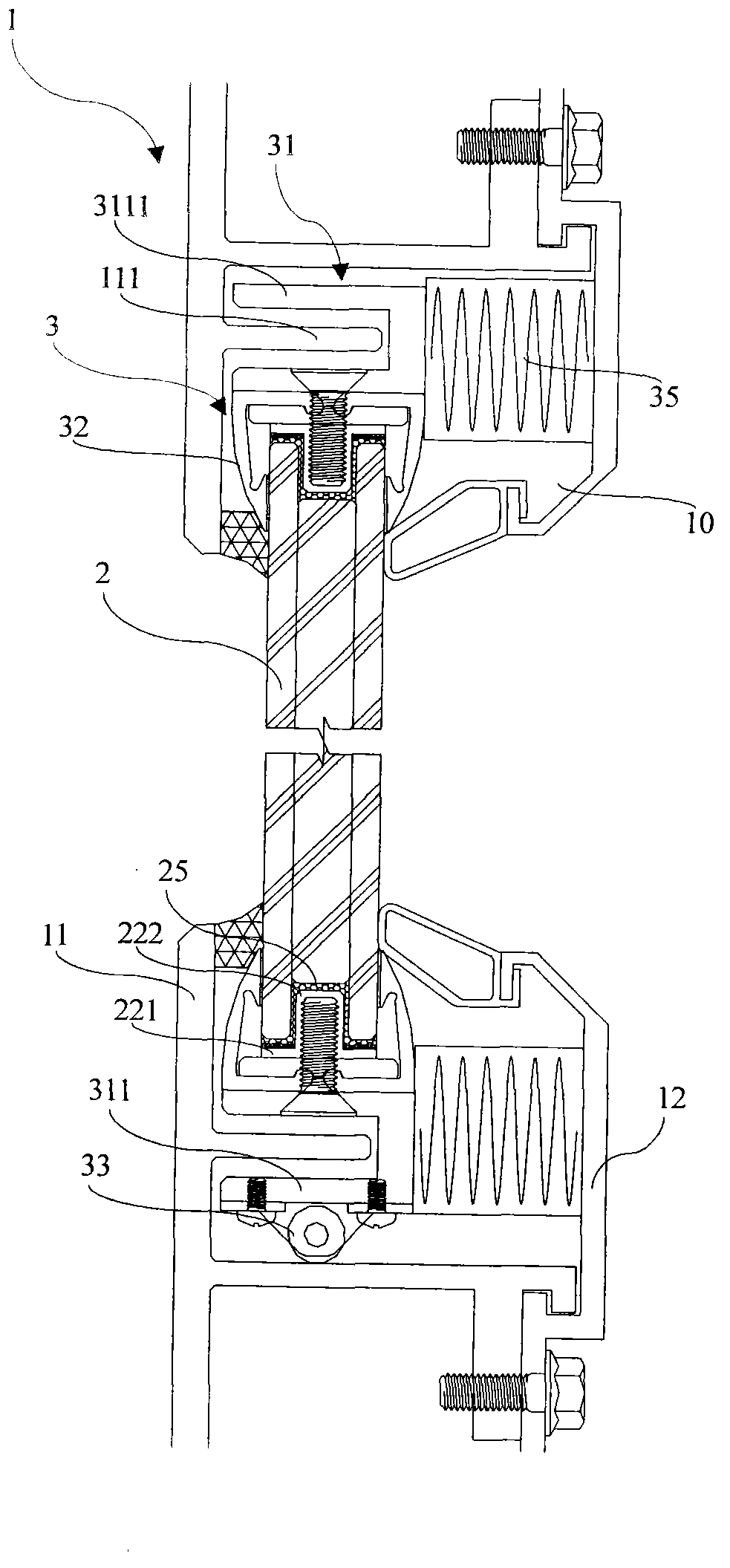

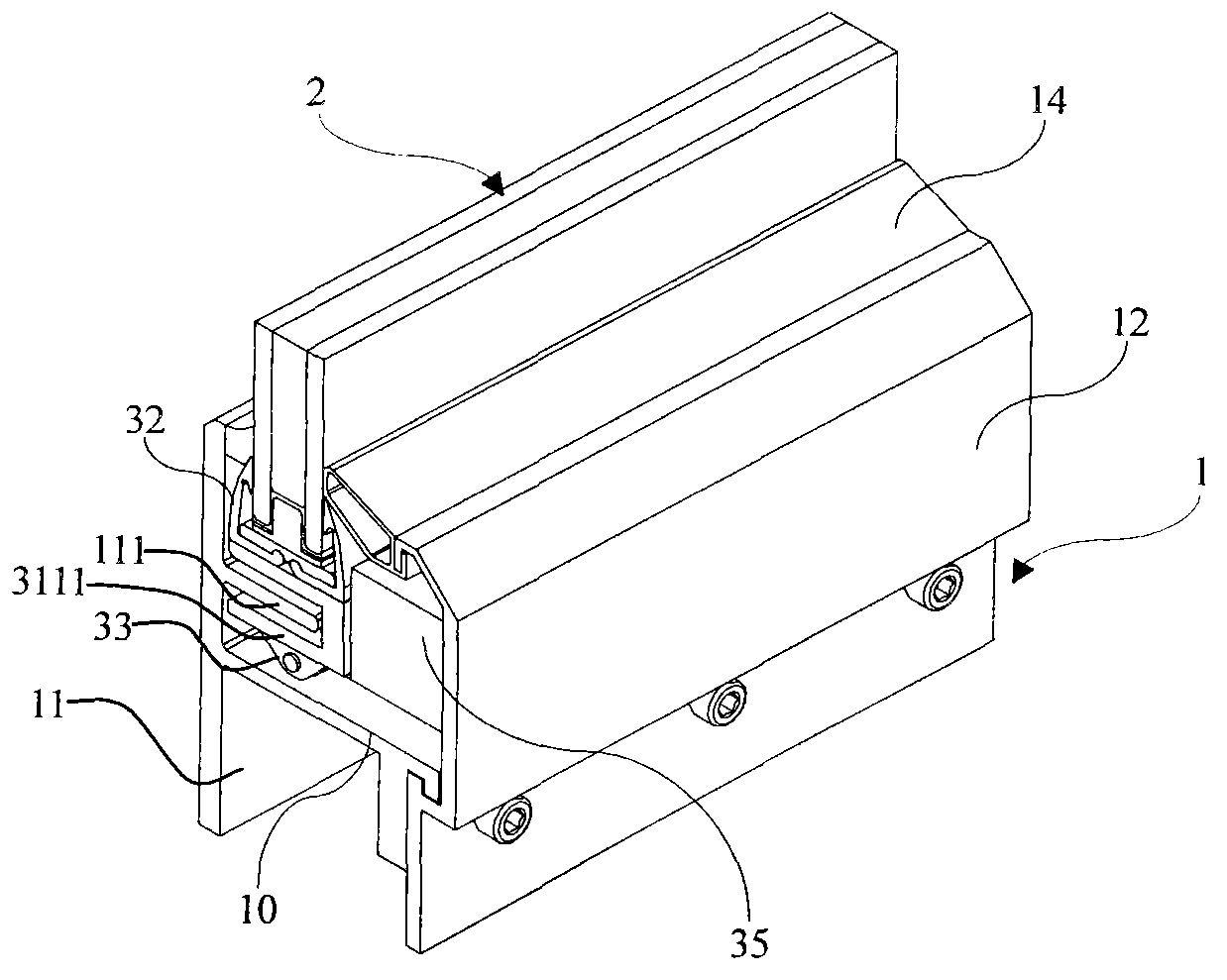

[0060] see Figure 1-2 , in the first preferred embodiment of the installation structure of a kind of helicopter cockpit transparent part of the present invention, comprise an installation frame body 1 and be fixed on the cockpit transparent part 2 of helicopter main body 5 by installation frame body 1 (can choose explosion-proof glass or bulletproof for use glass, etc., not limited); the installation frame body 1 is formed with a first installation groove 10, and the side of the cockpit transparent part 2 is inserted in the first installation groove 10; and the side of the cockpit transparent part 2 is combined with a frame 3. A cooperating installation structure is formed between the frame body 3 and the first installation groove 10. The frame body 3 includes a pressing component 31 and a fastening component 32, which are compressed and fastened through the cooperation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com