Real-time runoff sediment content measuring device and measuring method

A technology for real-time measurement and sediment content, applied in the field of measurement, which can solve the problems of sediment content error, difficulty in accurate measurement, and decreased measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

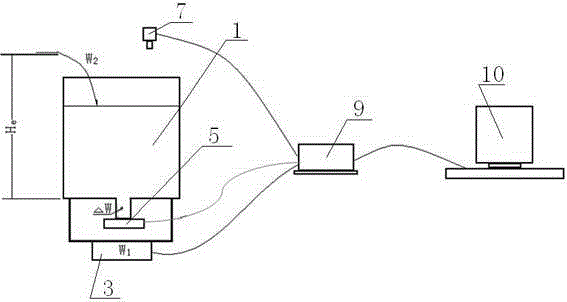

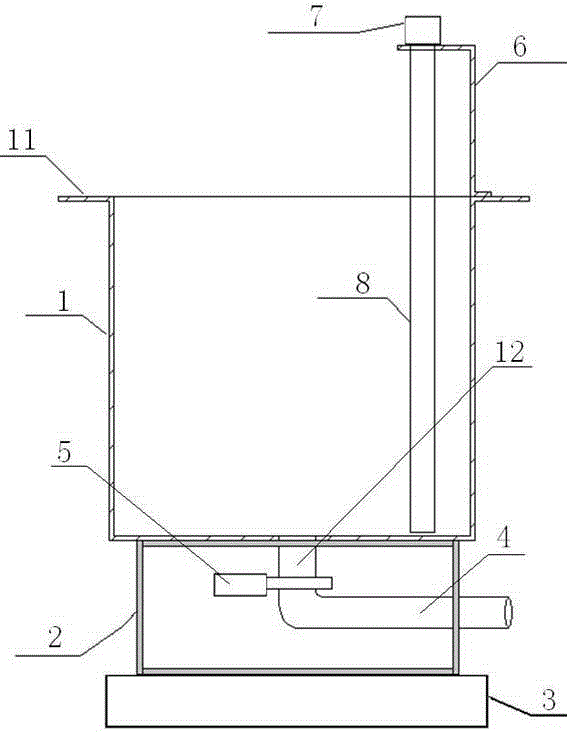

[0040] Example 1. The device of the present invention is composed of a measuring barrel 1, a load cell 3, a drain pipe 4, an electric valve 5, a liquid level sensor 7, a controller 9 and a processor 10. The measuring barrel 1 is placed on the load cell through the lower bracket 2. 3, the drain pipe 4 is connected to the bottom 1 of the measuring barrel, the electric valve 5 is installed on the drain pipe 4, the upper bracket 6 is fixed on the upper edge of the measuring barrel 1, the liquid level sensor 7 is installed above the measuring barrel 1 through the upper bracket 6, and the liquid The filter tube 8 of the level sensor 7 is in the measuring tank 1 , the controller 9 is respectively connected to the load cell 3 , the electric valve 5 and the liquid level sensor 7 , and the processor 10 is connected to the controller 9 . The top of the measuring barrel 1 is provided with a water tank that collects muddy water and injects it into the measuring barrel. There is a circle of...

example 2

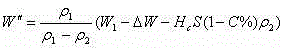

[0060] Example two, total runoff in device of the present invention and actual measurement process Same as Example 1, the actual effective sediment weight is:

[0061]

[0062] : The weight (Kg) of the runoff sediment in the bucket is considered to be measured by removing the residual muddy water in the bucket.

example 3

[0063] Example three, total runoff in the device of the present invention and the actual measurement process Same as Example 1, the actual effective sediment weight is:

[0064] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com