A Quick Clamping Device for Large Diameter Ultra-thin Plate

A clamping device and large-diameter technology, which is applied in installation, optics, instruments, etc., can solve the problems that it is difficult to ensure that the rotation axis passes through the center of the plate, it is difficult to provide a positioning reference, and it takes up a large space, so as to ensure high-precision measurement , simple operation, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

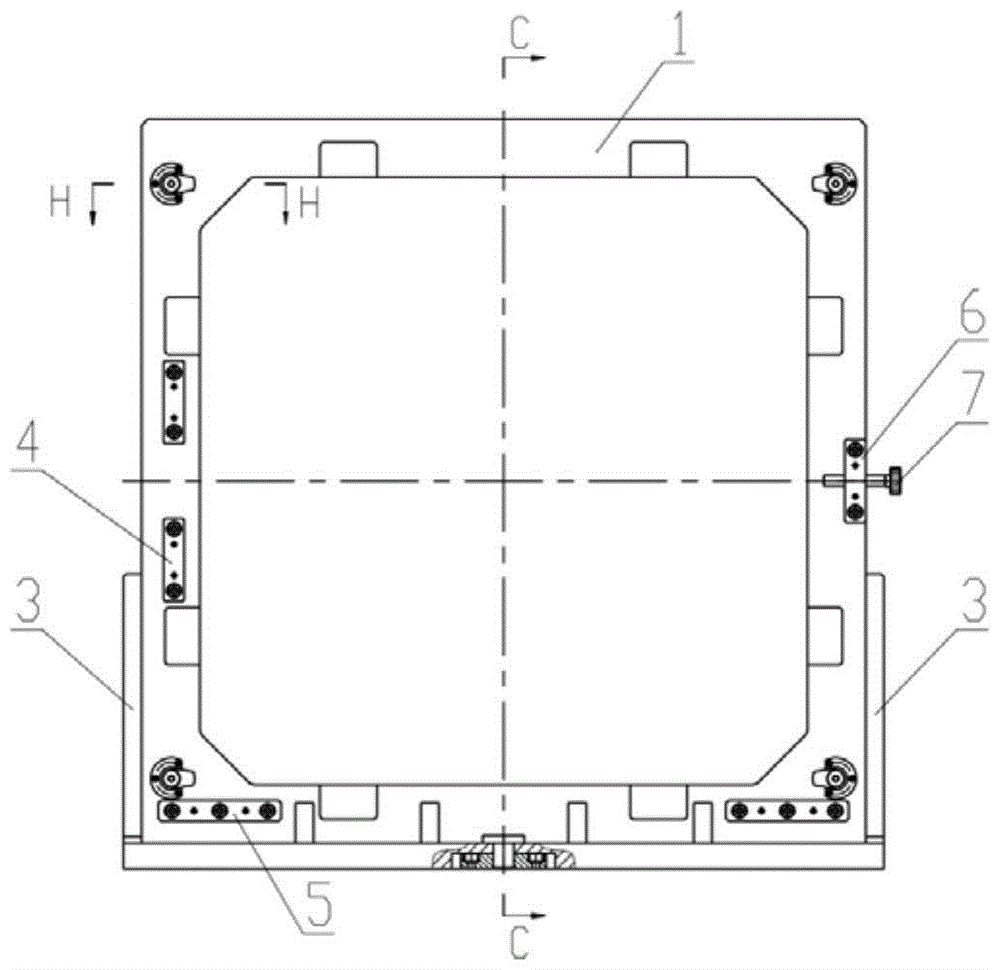

[0021] The present invention can quickly complete the positioning and locking of the plate group through the simple operation of "one leaning, two pushing, three pressing".

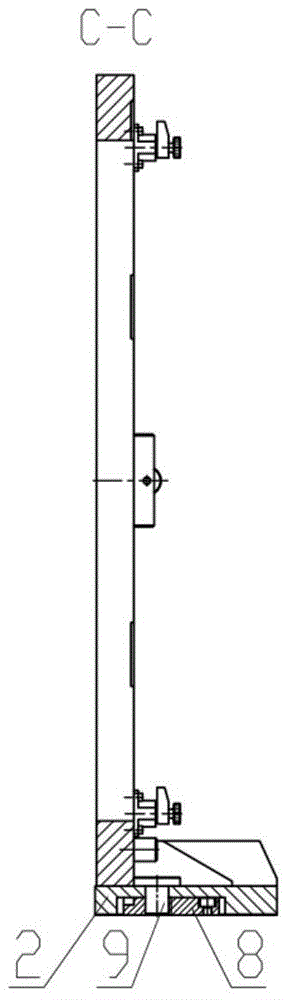

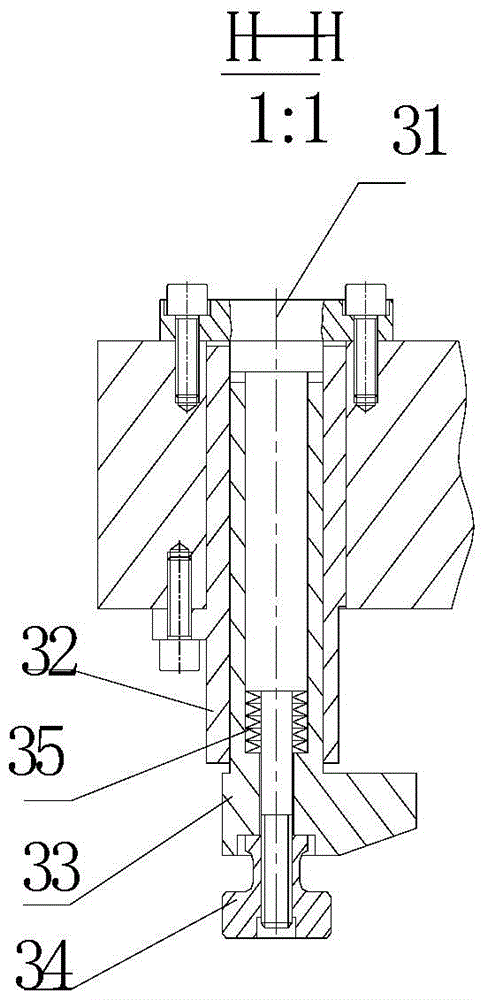

[0022] Such as figure 1 As shown, "one leaning" means that the three surfaces of the plate group are respectively supported on the main positioning plate, left positioning block and lower positioning block; ” is to rotate the compression knob to make the compression assembly support the plate group from the front. In order to ensure the positioning accuracy of the tooling, each positioning block is first installed on the positioning support, and then the positioning surface of the positioning block is trimmed to achieve the specified shape and position tolerance accuracy. The use of the disc spring ensures that the compression hook sleeve can slide up and down in the fixed bushing to achieve the purpose of compression or relaxation of the plate group.

[0023] Specifically, the fast clamping device for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com