Multi light source large view field spliced illumination system

An illumination system and a large field of view technology, applied in the field of integrated circuit equipment manufacturing, can solve the problems of decreased uniformity of the illumination field of view, unfavorable work of lithography equipment, etc., and achieve the effect of overcoming image surface unevenness and overcoming manufacturing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

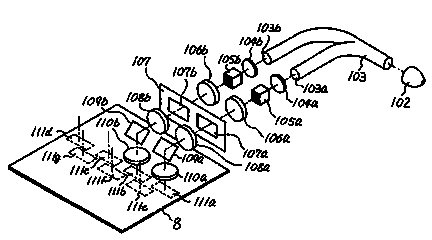

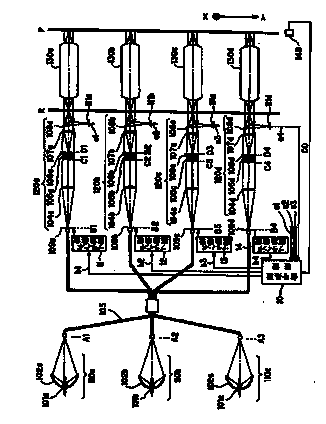

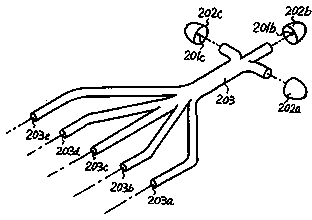

[0034] Such as Figure 5 As shown, the multi-light source and large field of view splicing lighting system of the present invention includes a plurality of light sources 1, and each light source 1 corresponds to a plurality of optical fibers 2, and the light passes through the plurality of optical fibers 2 and enters a plurality of coupling lens groups 3 respectively. The angle of the light coupled by the coupling lens group 3 is adjusted by the flat panel adjustment device 4, and then the light is uniformed by the uniform light device 5, and then passed through the relay lens group 6 to form the required illumination with a certain numerical aperture, size and uniformity on the mask plate 7 field of view. After passing through the projection objective lens 8 , a slit stop is set in the projection objective lens 8 , and a trapezoidal exposure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com