A processing method for a packaging substrate with a concave cavity structure

A technology for packaging substrates and processing methods, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing reliability, complex manufacturing process, and high cost, reducing processing costs, simplifying process, and improving The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

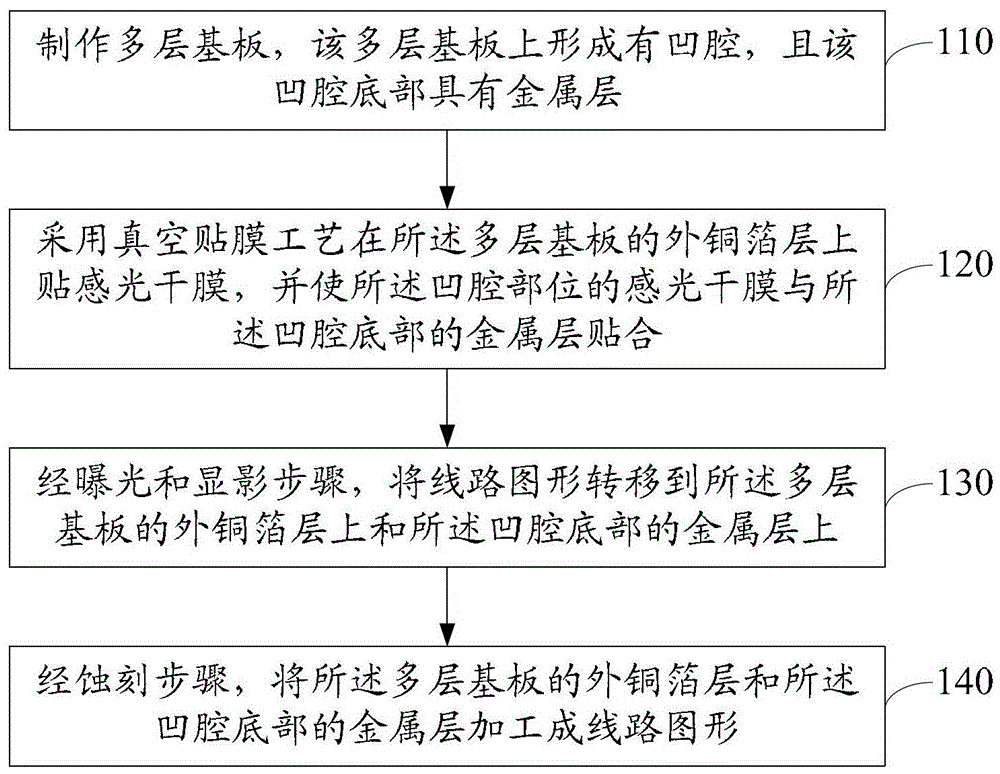

[0019] Please refer to figure 2 , an embodiment of the present invention provides a method for processing a packaging substrate with a cavity structure, including:

[0020] 110. Fabricate a multilayer substrate, where a cavity is formed on the multilayer substrate, and the bottom of the cavity is provided with a metal layer.

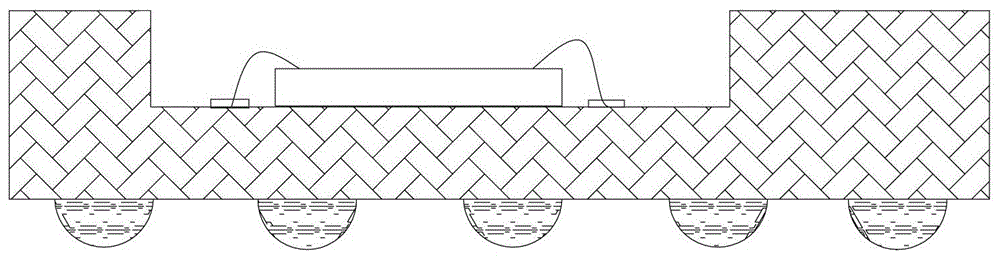

[0021] In this step, the bottom of the concave cavity formed on the multilayer substrate should at least reach the sub-outer circuit pattern of the multilayer substrate. In one embodiment, after the inner copper foil layer is processed into an inner layer circuit pattern, the outer insulating layer and the outer copper foil layer are sequentially laminated on the inner layer circuit pattern to make a multilayer substrate; It is mentioned that a concave cavity whose bottom reaches the inner circuit pattern is processed on the outer insulating layer and the outer copper foil layer. In another embodiment, after the inner copper foil layer can be processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com