Co2-facilitated transport membrane, and method for manufacturing same

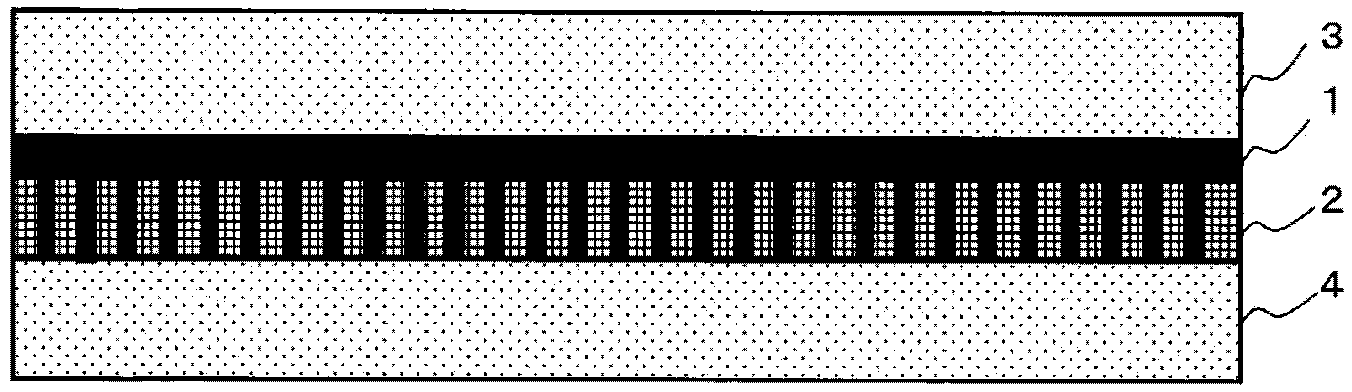

A manufacturing method and technology of porous membranes, applied in the field of CO2-facilitated transport membranes and their manufacture, capable of solving problems such as not exhibiting membrane characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

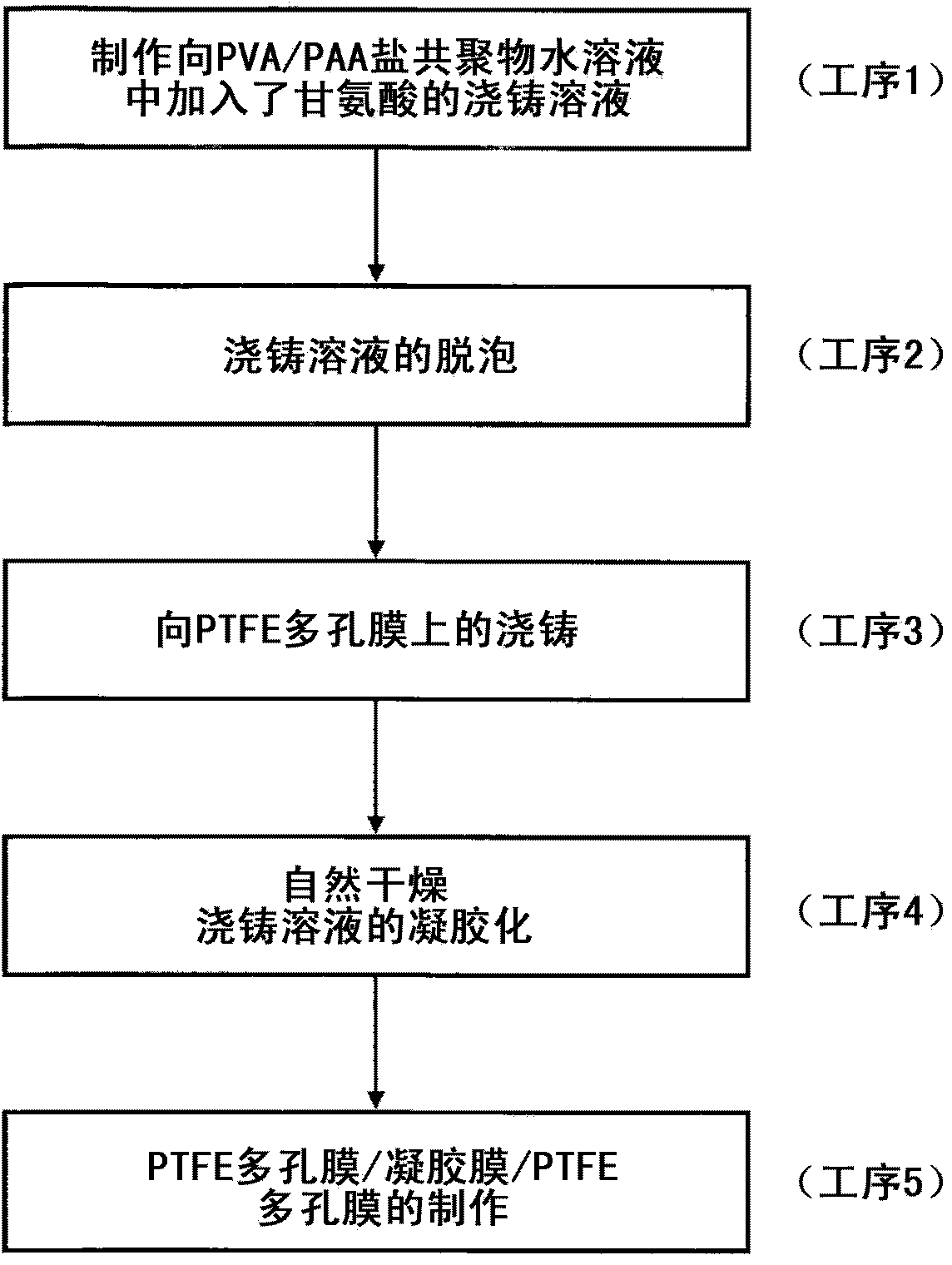

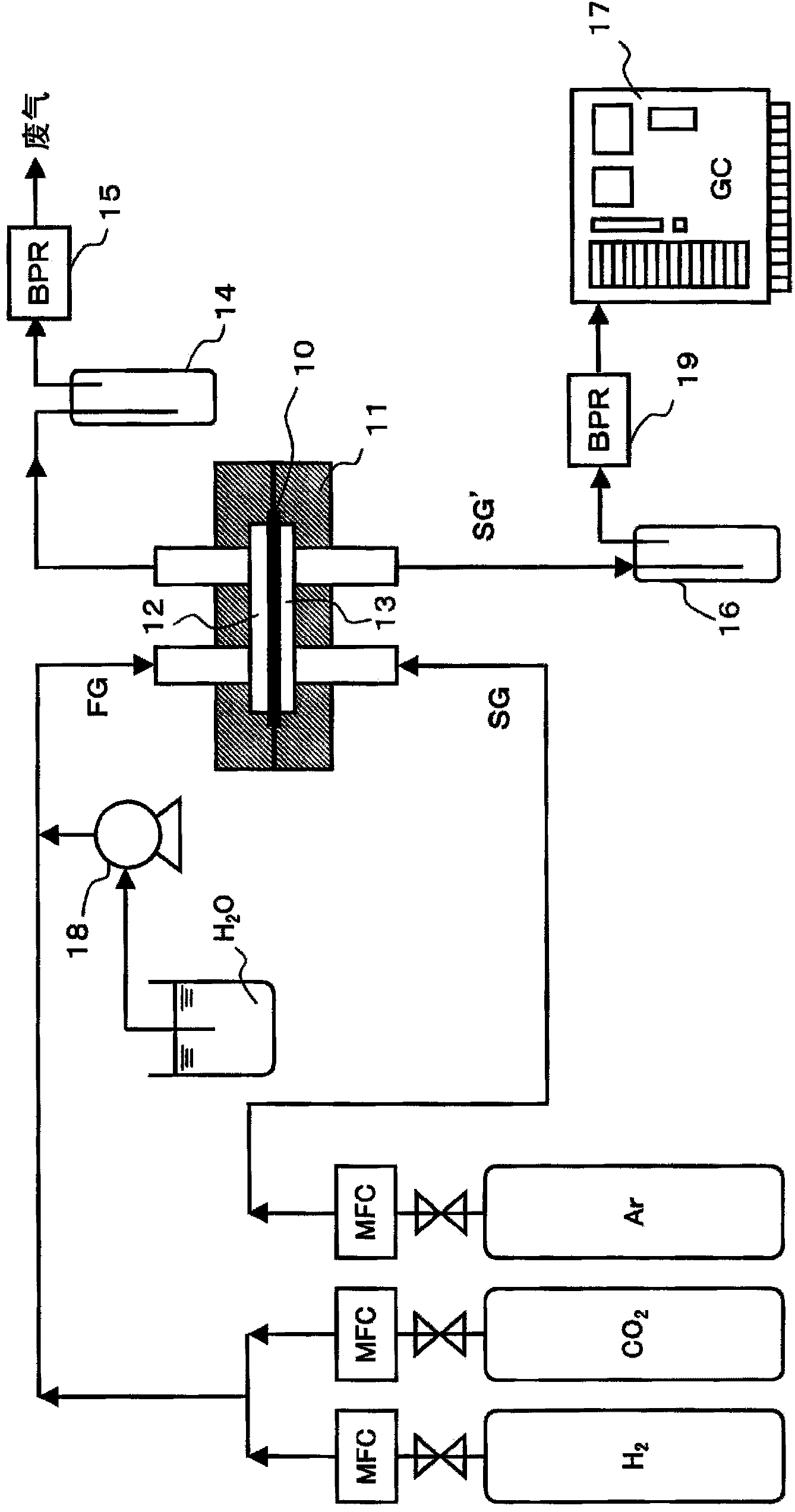

Method used

Image

Examples

Embodiment 1)

[0103] First, in Step 1 of preparing a casting solution, 0.366 g of glycine and 0.204 g of LiOH·H were added to 10 g of the PVA / PAA salt copolymer aqueous solution. 2 O, to obtain a casting solution. Hereinafter, the film of the present invention containing LiOH produced in this way is referred to as the film of the present invention of Example 1.

Embodiment 2)

[0105] Similarly, in the step 1 of preparing the casting solution, 0.366 g of glycine and 0.195 g of NaOH were added to 10 g of the PVA / PAA salt copolymer aqueous solution to obtain a casting solution. Hereinafter, the film of the present invention containing NaOH produced in this way is referred to as the film of the present invention of Example 2.

Embodiment 3)

[0107]Similarly, in the step 1 of preparing the casting solution, 0.366 g of glycine and 0.273 g of KOH were added to 10 g of the PVA / PAA salt copolymer aqueous solution to obtain a casting solution. Hereinafter, the film of the present invention containing KOH produced in this way is referred to as the film of the present invention of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com