A dark tea aroma-enhancing stacking processing device

A processing device and stacking technology, which is applied in the direction of pre-extraction tea treatment, etc., can solve the problems that the environmental sanitation conditions of stacking do not meet the clean production, insufficient fermentation at the stacking edge, and difficult to grasp the quality, so as to improve the taste and taste, and save energy. The effect of space, shortening cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

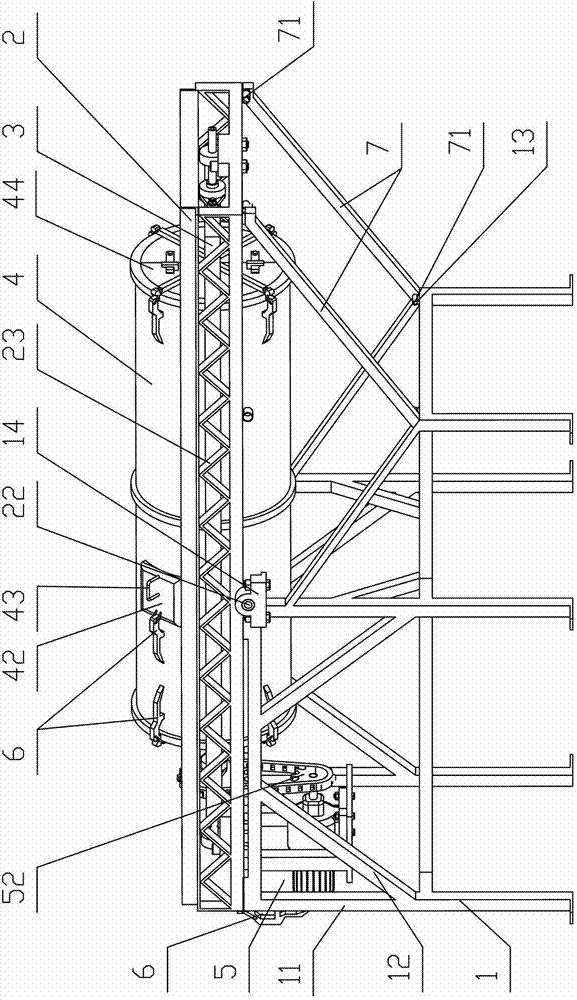

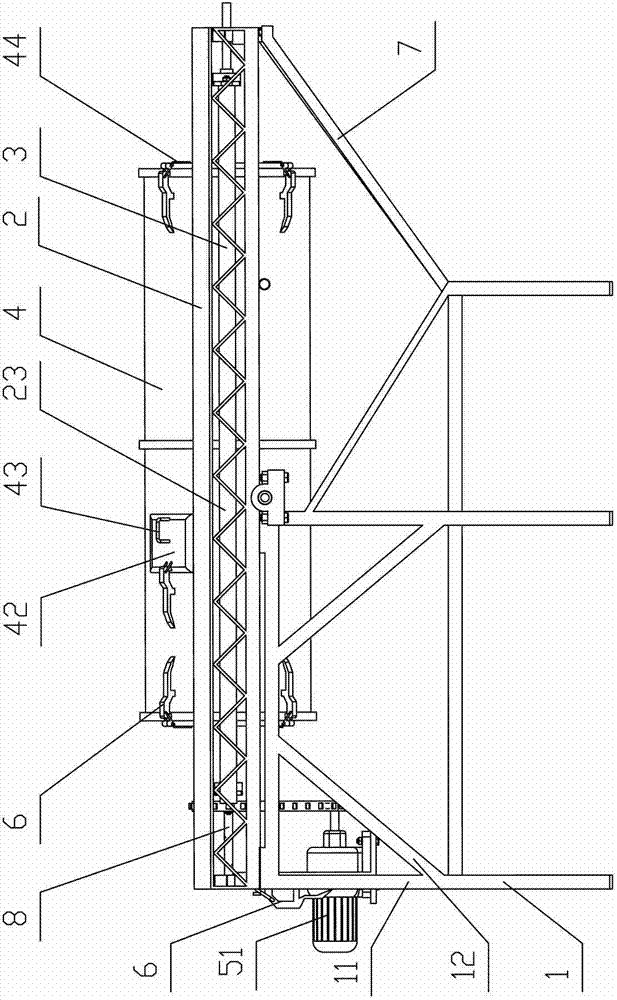

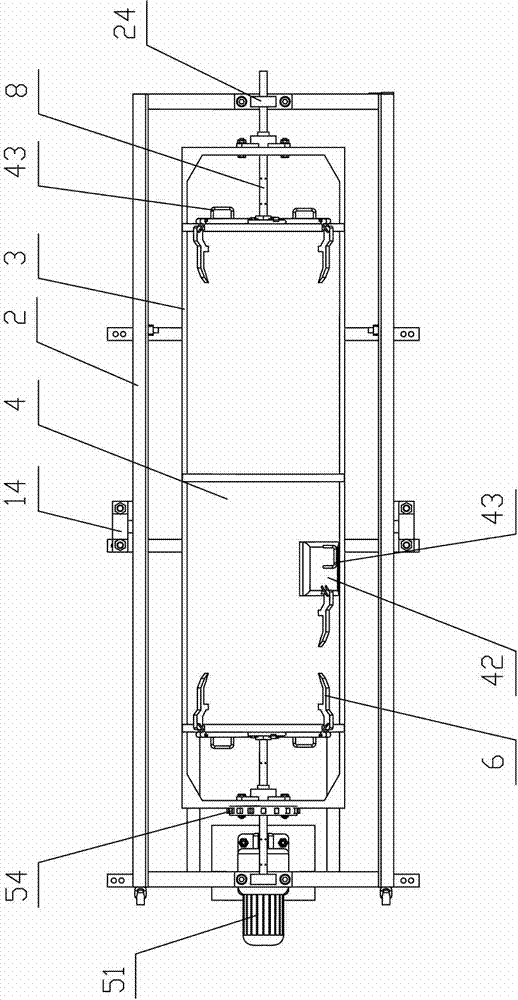

[0023] see Figure 1-Figure 4 Shown, the present invention is a kind of dark tea flavoring pile processing device, and it comprises frame 1, tilting frame 2, rotating frame 3, cylinder body 4 and power unit 5. in:

[0024] The frame 1 is an L-shaped frame body connected by several struts 11 , and several reinforcing rods 12 are arranged between the struts 11 .

[0025] The tilting frame 2 is placed horizontally above the frame 1, its front end is connected and fixed with the frame 1 through a hasp 6, and its rear end is fixed with the frame 1 through a support rod 7, and the two ends of the support rod 7 are respectively provided with inserting posts. 71, the rear ends of the frame 1 and the inclined frame 2 are respectively provided with sockets 13, 21 corresponding to the post 71, and the post 71 at both ends of the support rod 7 are respectively inserted into the sockets 13, 21 to fix the frame 1 with tilting frame 2. The middle part of the frame 1 and the tilting frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com