Fine dried noodles made of pure buckwheat flour and convenient to eat

A technology for buckwheat noodles and dried noodles, applied in application, food preparation, food science and other directions, can solve the problems of poor gas holding performance and lack of gluten elasticity, and achieve the effects of good curing, fragrant tendons and smooth and delicate taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

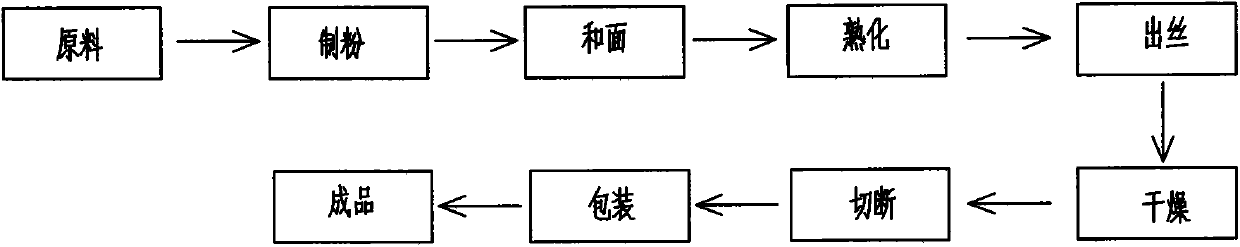

[0027] Embodiment 1: as figure 1 As shown, the instant edible pure buckwheat vermicelli is processed according to the following steps by 100 parts by weight of raw material buckwheat flour, an appropriate amount of salt, and an appropriate amount of water:

[0028] Step 1: Milling

[0029] The buckwheat is crushed into buckwheat flour, passed through an 80-mesh fine sieve, weighed according to the above parts for later use.

[0030] Step two: face to face

[0031] Put the weighed buckwheat flour into the noodle mixer, add 30 parts by weight of water and an appropriate amount of salt to 100 parts by weight of the buckwheat flour and mix well for 8 minutes.

[0032] Step 3: Ripening

[0033] Put the well-mixed noodles into the variable-pitch single-screw curing machine, and control the temperature of the jacket at the front part to 70°C, the middle part to 120°C, and the rear part to 140°C; the screw speed is controlled at 62r / min; The pressure is controlled at 3 / Cm 2 Extru...

Embodiment 2

[0040] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0041] Step two: face to face

[0042] Put the weighed buckwheat flour into the noodle mixer, add 33 parts by weight of water and an appropriate amount of salt to 100 parts by weight of the buckwheat flour and mix well for 10 minutes.

[0043] Step 3: Ripening

[0044] Put the well-mixed noodles into the variable-pitch single-screw curing machine, and control the temperature of the jacket at the front part at 80 °C, the middle part at 130 °C, and the rear part at 150 °C; the screw speed is controlled at 72 r / min; the working Pressure control at 4Kg / Cm 2 Extrude mature thick strips under certain conditions.

[0045] Step 3: Silk out

[0046] Put the mature thick strips directly into the single-screw extruder with variable pitch, and control the jacket temperature at 150°C; control the screw speed at 72r / min; control the working pressure at 6Kg / Cm 2 extruded into filaments.

[004...

Embodiment 3

[0048] Embodiment 3: Embodiment 3 is basically the same as Embodiment 1, and the difference is that in the aging process of the third step, the fully mixed noodles are put into the variable-pitch single-screw aging machine. The jacket temperature is controlled at 75°C in the front, 125°C in the middle, and 130°C in the rear; the screw speed is controlled at 67r / min; the working pressure is controlled at 3Kg / Cm 2 Extrude mature thick strips under certain conditions.

[0049] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com