Energy saving control method for hydraulic unit drive system

A hydraulic unit, energy-saving control technology, applied in the direction of presses, manufacturing tools, etc., can solve the difficult problem of idle running of the motor pump unit in standby and small flow demand, and the difficulty in matching the installed power of the hydraulic machine with the actual power demand, etc. Achieve the effects of improving implementation flexibility, improving time utilization, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

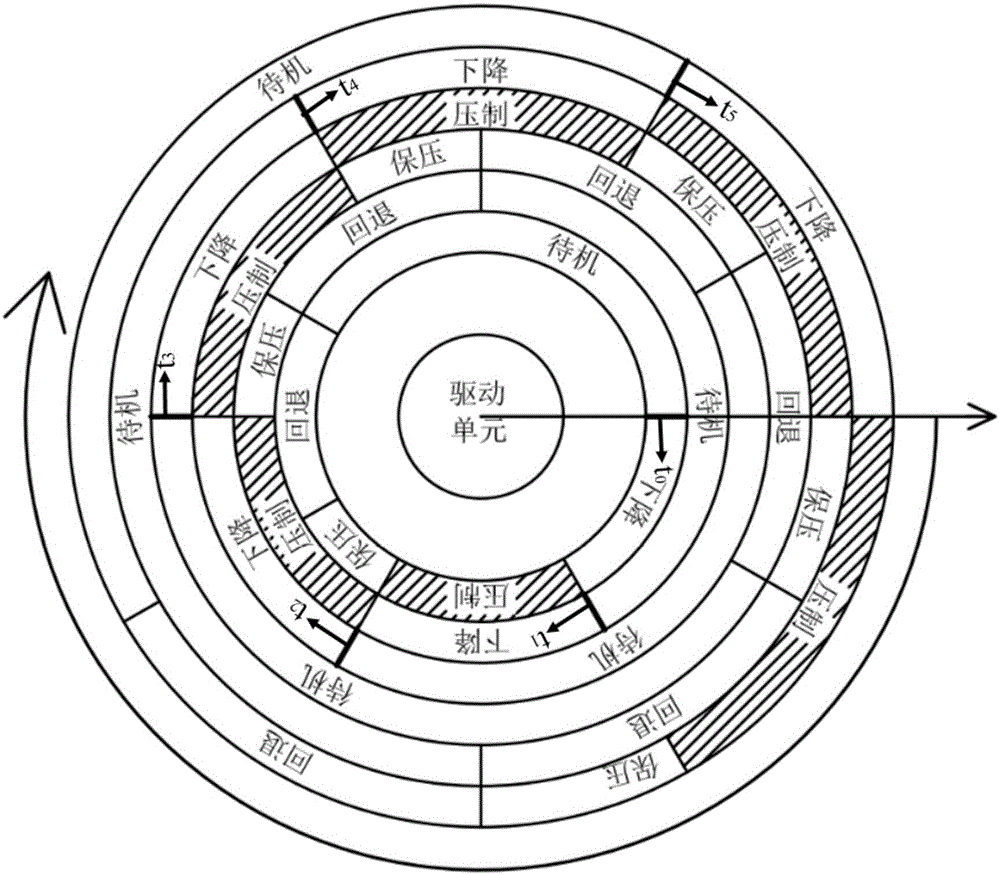

[0019] The energy-saving control method for the drive system of the hydraulic unit in this embodiment is as follows: centrally arrange multiple hydraulic machines with the same installed power, establish a clustered hydraulic unit, set the only pump station as the power source of the hydraulic unit, Divide a pumping station into different power areas, and the different power areas are: descending area, pressing area, holding pressure area, return area and auxiliary area; the descending area is used to provide the required flow and pressure for the hydraulic press to go down ;The pressing area is used to provide the flow and pressure required for the forming and pressing function of the hydraulic press; the holding area is used to provide the flow and pressure required for maintaining the pressure of the hydraulic press; the return area is used to provide the flow and pressure required to realize the return of the hydraulic press; the auxiliary area is used to provide The flow a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com