dispatch winch system

A technology for dispatching winches and hydraulic control systems, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of difficult maintenance of counterweight dispatching winch equipment, high risk factor of high-altitude operation, insufficient tension of wire rope, etc. Low requirements, light weight, complete intelligent protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

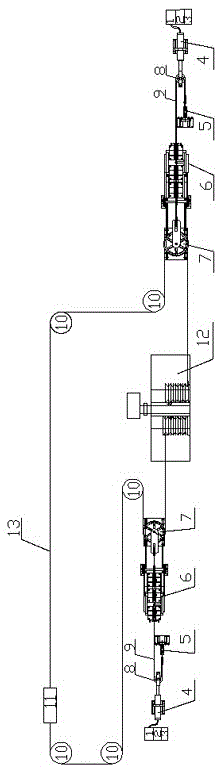

[0023] A dispatching winch system, comprising a dispatching winch 12 and an iron bull 11, the dispatching winch 12 passing through the steel wire rope II13 and the iron bull 11, the steel wire rope II13 is wound on the drum of the dispatching winch 12, and the two ends of the steel wire rope II13 respectively go around several guide wheels 10 and iron bulls. The connection between the forward end and the backward end of Niu 11 also includes the civil foundation and the hydraulic control system fixed on the civil foundation, of which there are two sets of hydraulic control systems, and the two sets of hydraulic control systems are respectively connected to the wire rope II13 located on both sides of the dispatching winch 12 .

[0024] The hydraulic control system includes a control box 1, a hydraulic device 2, a motor 3, a telescopic rod 4, a tension gauge 5, a counterweight 6 and a sports car wheel 7, the hydraulic device 2 is driven by the motor 3 and controlled by the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com