Composite warm-mixing regenerant and preparation method thereof

A technology of warm-mix regenerant and regenerant, which is applied in building insulation materials, building components, climate change adaptation, etc., to achieve the effects of cost reduction, utilization rate improvement, and good road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

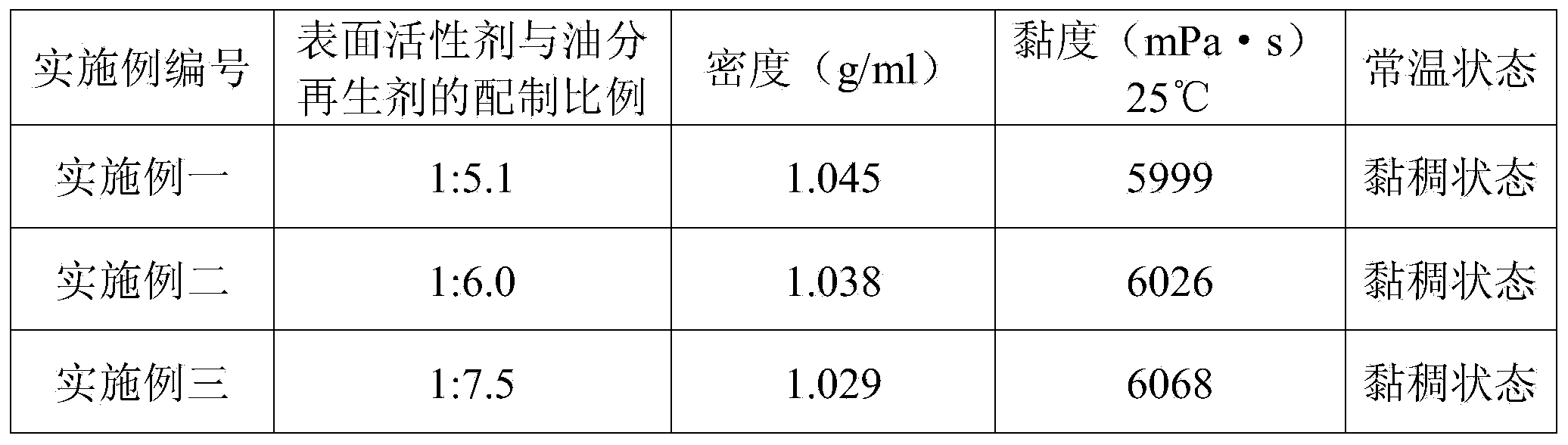

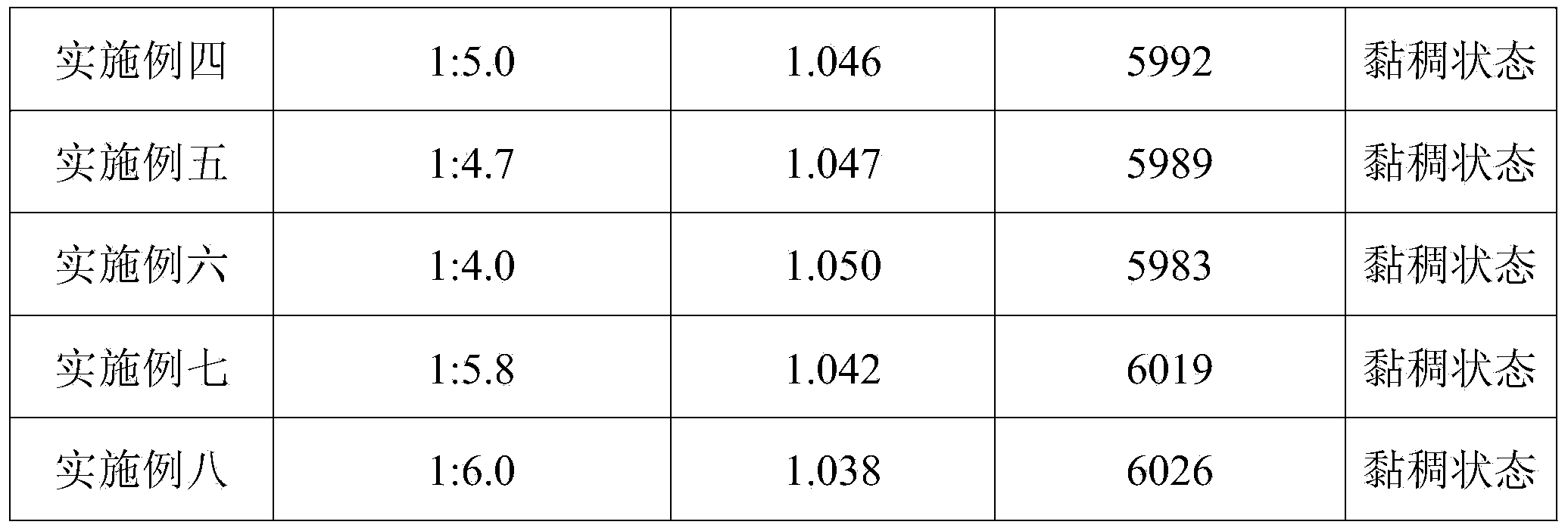

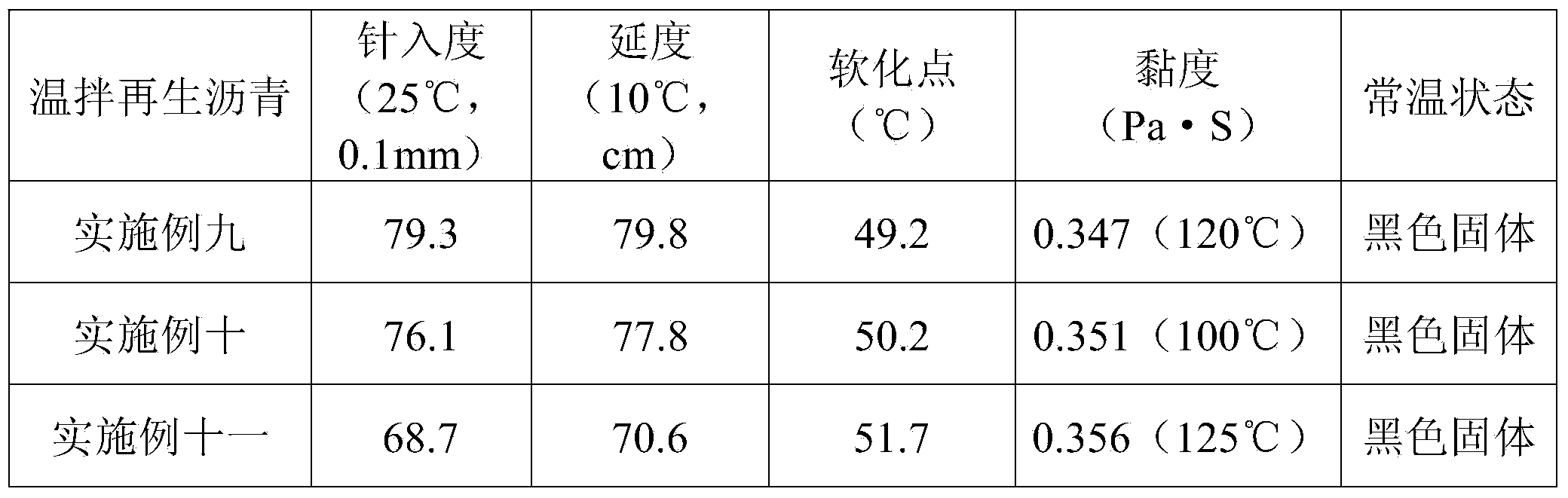

Embodiment 1

[0077] A composite warm-mix rejuvenator, which is composed of a surfactant and an oil rejuvenator. Among them, the surfactant is fatty acid glyceride, which is a yellow, transparent, liquid substance at room temperature, and the oil regeneration agent is the extracted oil from refined lubricating oil, which is a dark yellow, viscous liquid substance at room temperature.

[0078] Taking 5000g of asphalt binder as an example, the mass ratio of new asphalt to aged asphalt is 7:3, that is, the mass of new asphalt is 3500g, and the mass of aged asphalt is 1500g. The preparation method of above-mentioned composite warm mixing regeneration agent is as follows:

[0079] (1) Take fatty acid glyceride and the extracted oil when refining lubricating oil according to a certain ratio.

[0080] The amount of fatty acid glyceride added is 0.5% of the mass of asphalt binder, that is, P 脂肪酸甘油酯 =(P 1 +P 2 ) × A = 5000 × 0.5% = 25g; when the aged asphalt is regenerated to asphalt of the same...

Embodiment 2

[0084] A composite warm-mix rejuvenator, which is composed of a surfactant and an oil rejuvenator. The surfactant is sorbitan fatty acid, which is a yellow, transparent, liquid substance at normal temperature, and the oil regeneration agent is lubricating oil, which is a dark yellow, viscous liquid substance at normal temperature.

[0085] Taking 5000g of asphalt binder as an example, the mass ratio of new asphalt to aged asphalt is 7:3, that is, the mass of new asphalt is 3500g, and the mass of aged asphalt is 1500g. The preparation method of above-mentioned composite warm mixing regeneration agent is as follows:

[0086] (1) Sorbitan fatty acid and lubricating oil are weighed according to a certain ratio.

[0087] The amount of fatty acid sorbitan added is 0.3% of the mass of asphalt binder, that is, P 脂肪酸山梨坦 =(P 1 +P 2) × A = 5000 × 0.3% = 15g; when the aged asphalt is regenerated to asphalt of the same grade as the new asphalt, the amount of oil regeneration agent adde...

Embodiment 3

[0091] A composite warm-mix rejuvenator, which is composed of a surfactant and an oil rejuvenator. Among them, the surfactants are fatty acid glycerides and polysorbates, which are yellow, transparent, and liquid substances at room temperature, and the oil regeneration agent is lubricating oil and heavy oil, which are dark yellow and viscous liquid substances at room temperature.

[0092] Taking 5000g of asphalt binder as an example, the mass ratio of new asphalt to aged asphalt is 6:4, that is, the mass of new asphalt is 3000g, and the mass of aged asphalt is 2000g. The preparation method of above-mentioned composite warm mixing regeneration agent is as follows:

[0093] (1) The mixture of fatty acid glyceride and polysorbate and the mixture of lubricating oil and heavy oil are weighed according to a certain ratio.

[0094] The addition amount of fatty acid glyceride and polysorbate is 0.4% of the mass of asphalt binder, that is, P 脂肪酸甘油酯+聚山梨酯 =(P 1 +P 2 ) × A = 5000 × 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com