A four-lift self-assembly method for mobile formwork brackets

A technology for moving formwork and mounting frames, which is applied in erecting/assembling bridges, bridges, buildings, etc., to achieve the effects of reducing construction costs, simplifying installation work, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is a detailed description in conjunction with the drawings:

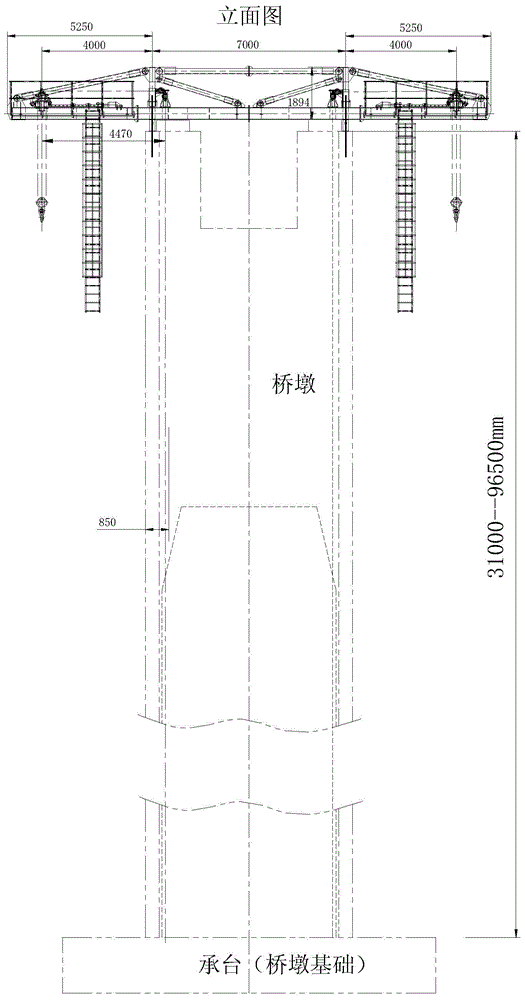

[0036] Such as figure 1 As shown, the construction process of the four-lifting self-assembly method of the mobile formwork bracket of the present invention, the specific construction process steps are:

[0037] The first step: Firstly, during the construction of the bridge pier structure, pre-embedded steel pipe legs, fixed small simple hoisting and hoisting equipment on the legs, and reserved thin steel wire ropes and safety ropes;

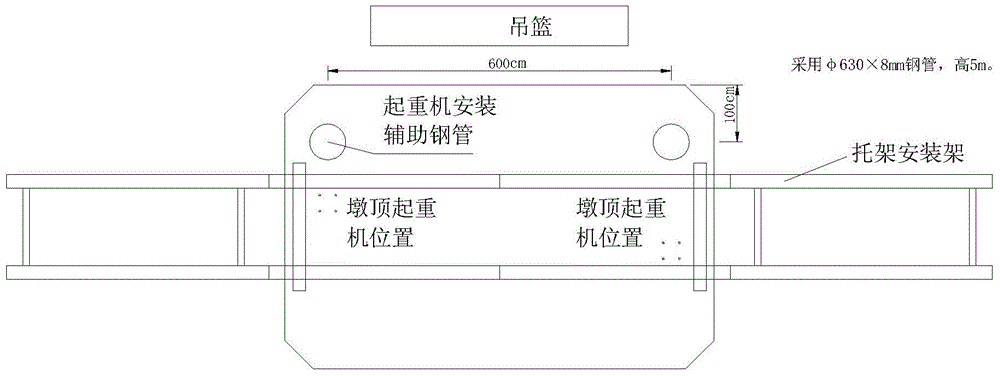

[0038] The second step: by reserving thin steel wire ropes and safety ropes, installing and using the construction hanging basket, the construction personnel and small accessories can go up and down the top of the pier (the first level of lifting);

[0039] Step 3: Lift and install the simple crane (second-level lifting) through the gondola and pier top profile steel cantilever system;

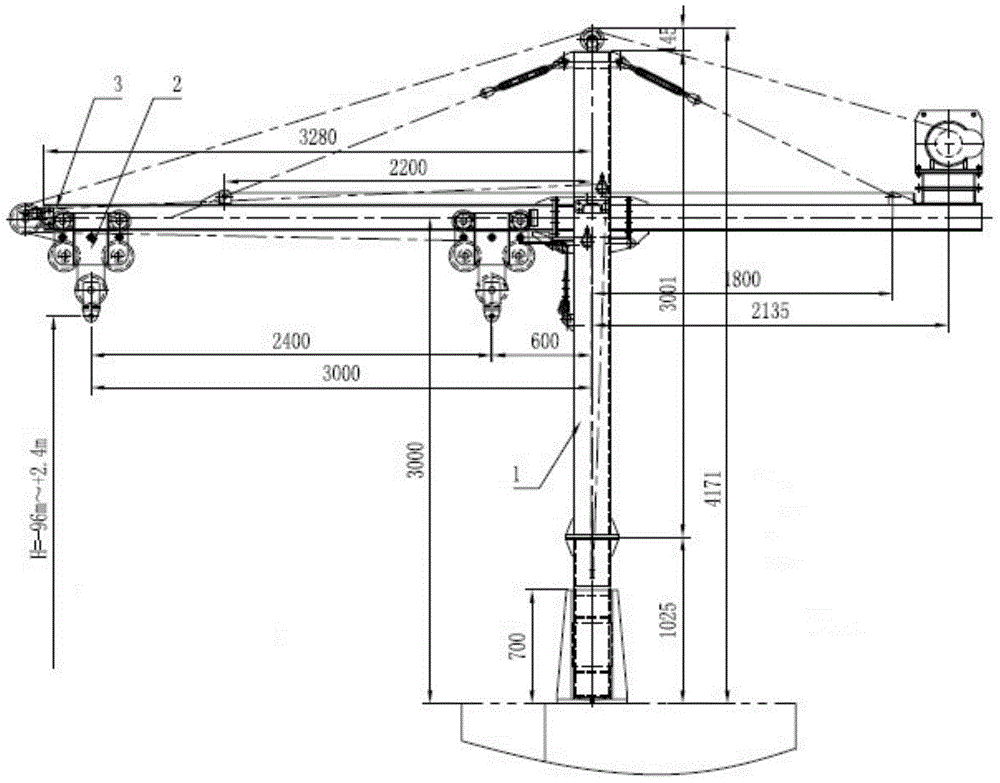

[0040] The fourth step: Lift and install the bracket mounting frame parts by a simple cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com